Automatic Numbering Machine Distributor

1/21

1/21

CN

CN

1/18

1/18

1/9

1/9

1/23

1/23

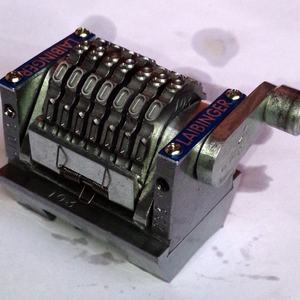

About automatic numbering machine distributor

Where to Find Automatic Numbering Machine Distributors?

China remains the global epicenter for automatic numbering machine manufacturing, with key production hubs concentrated in Shanghai, Zhejiang, and Guangdong provinces. These regions host vertically integrated supply chains that combine precision engineering, electronics assembly, and post-press machinery expertise. Shanghai and Hangzhou serve as innovation centers, producing high-speed digital control systems and smart paper processing units. Meanwhile, Dongguan and Ningbo specialize in cost-efficient mass production of mechanical and semi-automatic models, leveraging localized metal stamping and inkpad component suppliers.

The industrial clusters enable economies of scale, with many facilities operating under 5,000m²+ plants equipped for both standard and customized builds. Proximity to port infrastructure—such as Ningbo-Zhoushan and Shenzhen ports—reduces export lead times by 10–15% compared to inland manufacturers. Buyers benefit from rapid prototyping capabilities, modular design options, and flexible MOQs ranging from single units to multi-thousand-piece batches, depending on model complexity and automation level.

How to Choose Automatic Numbering Machine Suppliers?

Selecting reliable distributors requires a structured evaluation of technical, operational, and transactional indicators:

Technical & Production Capabilities

Prioritize suppliers with documented experience in precision mechanical assembly and electromechanical integration. Look for companies offering full-cycle development—from servo-driven numbering heads to touch-screen interface controls. Key benchmarks include:

- In-house R&D teams focused on paper feeding mechanisms, digit wheel calibration, and print consistency

- Integration of programmable logic controllers (PLCs) or industrial touch displays for batch numbering

- Production lines capable of handling A3 to A5 paper formats and up to 6-digit sequential printing

Quality Assurance and Compliance

While formal ISO 9001 certification is not universally listed, consistent performance metrics suggest robust internal quality systems. Top-tier suppliers maintain on-time delivery rates exceeding 98%, with response times under 3 hours. Verify compliance with international electrical safety standards where applicable, especially for motorized feeding systems. For office-grade self-inking models, assess durability through inkpad lifespan and housing material (typically zinc alloy or reinforced ABS).

Order Flexibility and Customization

Suppliers vary significantly in minimum order quantity (MOQ) and customization scope. Industrial-grade machines typically require 1-unit MOQs priced between $3,000–$5,000, while manual or desktop models are available in bulk quantities (1,500–2,000 pieces) at unit prices below $6. Customization options include digit count (4–8 digits), color coding, logo imprinting, packaging configuration, and software interface localization. Confirm whether firmware supports sequence reset, reverse numbering, or skip functions based on application needs.

Transaction Security and Verification

Leverage verifiable performance data such as reorder rates and online revenue volume. Suppliers reporting US $1M+ annual online turnover demonstrate market validation and logistical reliability. Cross-reference product listings with detailed specifications, including voltage requirements (AC/DC), power consumption, and dimensions. When possible, request sample testing to evaluate print clarity, paper jam frequency, and long-term mechanical wear.

What Are the Leading Automatic Numbering Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Shanghai Xsheen Machine Electron Technology Co., Ltd. | Paper Processing Machinery, Post-Press Equipment, Offset Printers | US $260,000+ | 100% | ≤12h | 50% | $3,000–$5,000 | 1 unit/set |

| Ningbo Emda Import And Export Co., Ltd. | Manual & Self-Inking Numbering Machines, Office Supplies | US $40,000+ | 100% | ≤4h | 16% | $3.99–5.45 | 1,500–2,000 pcs |

| Hangzhou Fuyang Sigo Office Supplies Co., Ltd. | Smart Paper Counting, Digital Creasing, Numbering Machines | US $1,500,000+ | 98% | ≤2h | 15% | $18–$3,200 | 1–20 units |

| Dongguan Nanbo Mechanical Equipment Co., Ltd. | Heavy-Duty Automatic Paper Numbering Machines | US $10,000+ | 100% | ≤3h | <15% | $3,500–$5,000 | 1 set |

Performance Analysis

Shanghai Xsheen stands out with a 50% reorder rate—the highest among listed suppliers—indicating strong customer retention, likely driven by consistent quality in industrial-grade equipment. Hangzhou Fuyang Sigo reports the highest online revenue (US $1.5M+), suggesting extensive market reach and diversified product offerings, including hybrid numbering and creasing solutions. Despite lower reorder rates, Dongguan Nanbo maintains perfect on-time delivery and fast response cycles, positioning it as a reliable choice for urgent procurement. Ningbo Emda specializes in low-cost, high-volume manual models suitable for office supply distribution networks.

FAQs

What is the typical lead time for automatic numbering machines?

Standard orders are fulfilled within 15–30 days after confirmation. Custom configurations involving PLC integration or specialized feeding mechanisms may extend lead times to 45 days. Air freight adds 5–7 days for international delivery, while sea shipping takes 25–35 days depending on destination.

Can suppliers provide machine samples?

Yes, most suppliers offer sample units for evaluation. Sample costs typically range from 1.5x to 2x the unit price for industrial models, with partial refunds upon full-order placement. For bulk manual units, sampling fees may be waived for orders exceeding 2,000 pieces.

Are automatic numbering machines compatible with international voltage standards?

Industrial models are commonly built for 220V/50Hz operation but can be adapted to 110V/60Hz upon request. Confirm voltage compatibility and request CE-marked power components if exporting to North America or Europe.

Do suppliers support OEM/ODM services?

Yes, multiple suppliers—including Ningbo Emda and Hangzhou Fuyang Sigo—explicitly list customization options for color, logo, packaging, and graphic design. For ODM projects, expect a development cycle of 3–6 weeks for prototype submission and testing.

What are the common applications of these machines?

Automatic numbering machines are primarily used in printing houses, banks, government offices, and educational institutions for serializing documents, invoices, certificates, and forms. Industrial variants integrate into offset printing lines, while desktop models serve small-scale administrative environments requiring high print accuracy and durability.