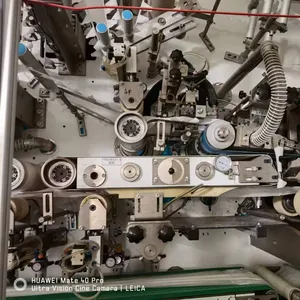

Automatic Papad Making Machine With Dryer

CN

CN

1/16

1/16

1/17

1/17

1/11

1/11

1/14

1/14

1/12

1/12

1/22

1/22

1/3

1/3

1/12

1/12

About automatic papad making machine with dryer

Where to Find Automatic Papad Making Machine with Dryer Suppliers?

China remains the central hub for industrial food processing equipment manufacturing, with key suppliers of automatic papad making machines with integrated dryers concentrated in Shandong, Henan, and Zhejiang provinces. These regions host vertically integrated production ecosystems that combine sheet metal fabrication, electrical control systems assembly, and food-grade surface treatment under one supply chain. Shandong and Zhejiang are particularly notable for specializing in automated food machinery, where proximity to stainless steel mills and component manufacturers reduces material lead times by 15–20% compared to offshore alternatives.

The industrial clusters support rapid prototyping and scalable production, enabling suppliers to fulfill both small-batch custom orders and high-volume exports efficiently. Facilities typically integrate CNC machining, welding automation, and final-line testing for continuous operation validation. Buyers benefit from localized access to technical engineers, third-party inspection services, and multimodal logistics networks—ensuring average delivery windows of 30–45 days for standard configurations. The ecosystem also supports customization in drying temperature range, output capacity (500–10,000 pcs/h), and compliance with international food safety standards.

How to Choose Automatic Papad Making Machine with Dryer Suppliers?

Selecting a reliable supplier requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to ISO 9001 quality management systems as a baseline. For export to regulated markets (EU, USA, GCC), confirm CE marking or equivalent conformity assessments covering electrical safety (IEC 60204) and food contact materials (FDA 21 CFR). Request documentation on motor efficiency ratings, thermostat calibration reports, and conveyor belt material certifications (e.g., FDA-approved silicone or PTFE).

Production Capability Assessment

Evaluate core infrastructure indicators:

- Minimum factory area exceeding 3,000m² to ensure dedicated assembly lines

- In-house engineering team capable of modifying roller die designs, drying chamber airflow dynamics, and PLC control interfaces

- Stainless steel processing capability (SUS304/SUS316) with polishing to Ra ≤ 0.8μm for hygienic surfaces

Cross-reference claimed capabilities with verified on-time delivery rates above 95% and response times under 4 hours to assess operational reliability.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services until post-arrival performance verification. Prioritize suppliers offering sample units for functional testing—particularly for drying uniformity and dough feeding consistency. Conduct virtual audits via live video walkthroughs of CNC workshops and final testing bays. Confirm inclusion of user manuals, spare parts kits, and remote troubleshooting support in quoted terms.

What Are the Best Automatic Papad Making Machine with Dryer Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shandong Huake Machinery Technology Co., Ltd. | Shandong, CN | $30,000+ | 100% | ≤2h | <15% | Color, size, logo, packaging, label, graphic | 1–5 sets | $8,500–36,000 |

| Anhui Vsee Optoelectronic Technology Co., Ltd. | Anhui, CN | $50,000+ | 25% | ≤3h | 50% | Limited (indirect product alignment) | 1 set | $18,000–45,000 |

| Hangzhou Bear Machinery Co., Ltd. | Zhejiang, CN | $520,000+ | 100% | ≤4h | 100% | Power, color, capacity, material, logo, modular design, solar-powered options | 1 set | $3,000–26,800 |

| Zhengzhou Yugong Construction Machinery Co., Ltd. | Henan, CN | $860,000+ | 100% | ≤2h | 37% | Color, material, size, logo, packaging, label | 1 set | $3,299–7,580 |

| Shijiazhuang Zengtuo Trading Co., Ltd. | Hebei, CN | $10,000+ | 100% | ≤1h | 33% | Fuel type, configuration, shapes, output options, pulp capacity | 1 set | $14,500–185,000 |

Performance Analysis

Hangzhou Bear Machinery stands out with the highest reorder rate (100%) and extensive customization depth, indicating strong customer satisfaction despite longer response cycles. Shandong Huake offers competitive entry-level pricing starting at $8,500 with full customization, backed by perfect on-time delivery. Zhengzhou Yugong presents cost-effective solutions below $7,600 but focuses primarily on egg tray machinery, suggesting limited specialization in food processing. Anhui Vsee shows a high reorder rate yet lacks direct papad machine listings, raising concerns about product relevance. Shijiazhuang Zengtuo commands premium pricing up to $185,000, likely reflecting large-scale or fully integrated production lines suitable for industrial clients. Prioritize suppliers with documented food machinery experience, clear technical specifications, and verifiable after-sales service channels.

FAQs

How to verify supplier credibility for papad making machines?

Cross-check ISO or CE claims with certification databases. Request test videos demonstrating dough rolling consistency, dehydration levels (target: ≤10% moisture content), and PLC interface functionality. Analyze customer reviews focusing on uptime, spare parts availability, and technician responsiveness.

What is the typical lead time for customized machines?

Standard units ship within 30 days. Customized configurations involving modified drying tunnels, multi-tier conveyors, or special voltage requirements require 45–60 days, including pre-shipment testing.

Can suppliers accommodate low MOQs for trial runs?

Yes, multiple suppliers offer single-set orders, especially for initial market testing. Units priced between $3,000–$9,500 typically support MOQ = 1, providing flexibility for SMEs and startups.

Do manufacturers provide installation and training support?

Most suppliers include basic setup guides and video tutorials. On-site commissioning and operator training are often available at additional cost—confirm availability and associated travel fees before order placement.

What drying technologies are used in these machines?

Common methods include electric-heated convection dryers, LPG spray systems, and microwave-assisted dehydration. Selection depends on desired throughput, energy efficiency targets, and final product texture requirements.