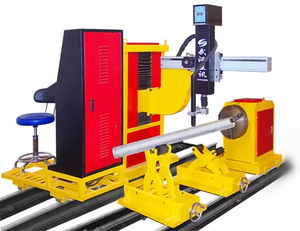

Automatic Pipe Cutting Machine Price In India

CN

CN

About automatic pipe cutting machine price in india

Where to Find Automatic Pipe Cutting Machine Suppliers?

China remains the dominant hub for automatic pipe cutting machine manufacturing, with key industrial clusters in Henan, Shandong, and Qingdao offering specialized production ecosystems. Henan province hosts advanced CNC and laser equipment manufacturers, leveraging Zhengzhou’s strategic logistics network for efficient export distribution. Shandong's machinery corridor supports integrated metalworking supply chains, enabling cost-optimized fabrication of high-torque cutting systems. Qingdao specializes in plastic and HDPE pipe processing machinery, serving infrastructure and utility sectors with custom automation solutions.

These regions feature vertically integrated facilities capable of end-to-end production—from raw material processing to final assembly—reducing lead times by up to 30% compared to decentralized models. Buyers benefit from concentrated technical expertise, localized component sourcing, and scalable output capacities. Typical advantages include MOQ flexibility (1 set for standard models), 20–35% lower unit costs versus Western suppliers, and rapid prototyping capabilities for customized configurations. Lead times for standard orders range from 25–45 days, depending on complexity and automation level.

How to Choose Automatic Pipe Cutting Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify ISO 9001 certification as a baseline for quality management systems. For international compliance, ensure CE marking for electrical safety and mechanical regulation adherence. Laser-based pipe cutters must meet IEC 60825 standards for laser radiation safety. Request documentation on motor efficiency ratings, control system specifications (e.g., Siemens or Delta PLCs), and cutting accuracy under load conditions.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum factory area of 3,000m² for sustained volume output

- In-house CNC machining, welding, and automation integration capabilities

- Dedicated R&D teams focused on motion control, feeding mechanisms, and software interface development

Cross-reference on-time delivery rates (target ≥98%) and response times (≤2 hours) as indicators of operational reliability.

Transaction Security & Quality Assurance

Utilize secure payment methods such as escrow services to mitigate risk until post-delivery inspection. Prioritize suppliers with verifiable reorder rates and documented after-sales support frameworks. Conduct pre-shipment inspections to validate dimensional accuracy, surface finish quality, and alignment precision. Sample testing should assess cycle time consistency, kerf width tolerance (±0.1mm), and thermal distortion control in laser-cut sections.

What Are the Best Automatic Pipe Cutting Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Product Range (USD) | Min. Order | Customization |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Chenxing Intelligent Equipment Co., Ltd. | Laser Cutting Machines, CNC Plasma Cutters, Laser Welders | 100% | ≤1h | $20,000+ | - | $4,600–6,240 | 1 set/piece | Standard models only |

| INDER INDUSTRIES | Pipe Cutters, Tube Bending Machines, Hand Tools | - | ≤6h | - | - | $1.86–110 | 100 pieces | OEM/ODM available |

| Qingdao Polyfusion Machinery Co., Ltd. | Plastic Pipe Cutting, HDPE Processing, Portable Units | 100% | ≤2h | $60,000+ | 29% | $260–45,000 | 1 set | Color, size, logo, packaging |

| Shandong Bondway Machinery Co., Ltd. | Pipe Cutting Machines, Agricultural Sprayers, Harvesters | 98% | ≤2h | $60,000+ | <15% | $210–620 | 1 set/acre | Limited customization |

| Anji Qingyun Intelligent Equipment Co., Ltd. | CNC Laser Pipe Cutters, Automatic Feeding Systems | 100% | ≤1h | $300,000+ | <15% | $25,888–79,999 | 1 set | Full engineering customization |

Performance Analysis

Zhengzhou Chenxing and Anji Qingyun represent premium-tier suppliers focusing on high-precision CNC fiber laser systems, with price points reflecting advanced motion control and feeding automation. Anji Qingyun’s $300,000+ annual online revenue indicates strong export performance and scalability. Qingdao Polyfusion stands out for plastic pipe applications, offering broad customization and competitive pricing for mid-range buyers. Shandong Bondway provides cost-effective semi-automatic solutions but shows limitations in order scalability and customization depth. INDER INDUSTRIES targets low-cost manual and silicone hose cutting segments, unsuitable for industrial-grade automation needs.

FAQs

How to verify automatic pipe cutting machine supplier reliability?

Confirm ISO 9001 or CE certifications through official registries. Request factory audit reports, video walkthroughs of production lines, and client references. Analyze transaction history, focusing on consistent on-time delivery and responsive communication. Third-party inspection agencies can conduct pre-shipment quality audits.

What is the typical lead time for automatic pipe cutting machines?

Standard models ship within 25–35 days after order confirmation. Customized CNC or laser systems require 40–60 days for design validation, component procurement, and testing. Expedited builds may reduce timelines by 10–15% at additional cost.

Do suppliers offer customization options?

Yes, leading suppliers like Qingdao Polyfusion and Anji Qingyun provide full customization including pipe diameter range (e.g., 75–800mm), feeding mechanism type (manual, semi-auto, servo-driven), control interface language, and branding elements. Engineering modifications require technical drawings and feasibility assessment.

What are common materials processed by these machines?

Automatic pipe cutting machines handle carbon steel, stainless steel, aluminum, copper, PVC, HDPE, and PPR. Laser models excel in metal tubes with wall thicknesses up to 12mm, while mechanical cutters are preferred for thermoplastic piping due to clean, burr-free cuts.

Are samples available before bulk ordering?

Most suppliers offer sample units for evaluation, typically charged at 30–50% above wholesale price, which may be credited toward future orders. Sample lead time ranges from 15–25 days, depending on configuration complexity.