Automatic Production Line Producer

1/18

1/18

1/18

1/18

1/14

1/14

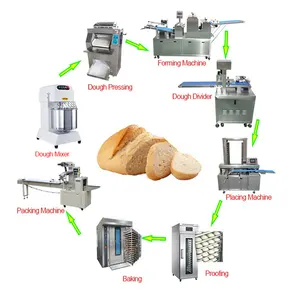

About automatic production line producer

Where to Find Automatic Production Line Producer Suppliers?

Global sourcing for automated production systems centers on specialized manufacturing hubs offering infrastructure and supply chain advantages. China’s Yangtze River Delta (Shanghai, Jiangsu) hosts precision engineering clusters with integrated electronics and robotics ecosystems, while the Pearl River Delta (Guangdong) provides cost-efficient high-volume solutions. Europe’s German Mittelstand excels in bespoke, high-precision automation, particularly for automotive and pharmaceutical sectors. North American suppliers in the U.S. Great Lakes region specialize in resilient, tech-forward systems with shorter lead times. Key advantages include localized component networks reducing logistics costs, regional certifications like CE or UL compliance, and sector-specific expertise—Guangdong’s consumer electronics focus versus Jiangsu’s chemical/packaging specializations. Industry exhibitions (Hannover Messe, IMTS) and verified B2B platforms facilitate direct access to these clusters.

How To Choose Automatic Production Line Producer Suppliers?

Prioritize technical capability alignment with your production requirements. Assess scalability through historical project portfolios—suppliers handling automotive-grade volumes (50,000+ units/month) typically demonstrate robust quality control. Mandatory certifications include ISO 9001 for process consistency and ISO 45001 for workplace safety compliance. For industry-specific needs:

- Food/pharma: Validate FDA or EHEDG-certified material handling

- Automotive: Require IATF 16949 documentation

- Electronics: Confirm ESD-safe assembly protocols

Quality verification should involve on-site audits examining:

- In-process testing stations for real-time defect detection

- Maintenance logs for equipment uptime history

- Third-party validation reports (e.g., SGS throughput accuracy tests)

Demand failure mode analysis documentation and benchmark response times for technical support—leading suppliers resolve 95% of line issues within 48 hours.

What Are the Best Automatic Production Line Producer Suppliers?

Top manufacturers demonstrate excellence across performance metrics critical for B2B procurement:

| Supplier | Review Score | Response Time | Online Revenue | Reorder Rate |

|---|---|---|---|---|

| Wuxi Yingrun Machinery Technology | 5.0/5.0 | ≤3h | $780,000+ | 100% |

| Zhengzhou Lonkia Machinery | 5.0/5.0 | ≤2h | $750,000+ | 53% |

| Guangdong Chaomai Automation Technology | 5.0/5.0 | ≤3h | $290,000+ | 50% |

| Zhangjiagang Bievo Machinery | 5.0/5.0 | ≤4h | $610,000+ | 100% |

| Shanghai SIEHE Mechanical | 5.0/5.0 | ≤10h | $74,000+ | <15% |

Wuxi Yingrun leads in client retention (100% reorder rate) and operational scale ($780K+ revenue), ideal for high-volume sectors. Zhengzhou Lonkia offers exceptional responsiveness (≤2h) and competitive pricing. Guangdong Chaomai balances rapid deployment with mid-volume flexibility. Zhangjiagang Bievo achieves perfect reliability scores for mission-critical applications. Shanghai SIEHE suits specialized low-volume projects with 100% on-time delivery.

FAQs

What is an automatic production line?

An automated production line is a manufacturing system with automated machines and equipment to produce efficiently and quickly. The automated production line is designed to perform a specific function or series of functions in a production process.

What is an automated assembly line manufacturer?

Assembly line automation involves using technology and machines to perform tasks that were traditionally done by humans. The goal is to boost all aspects of the line to produce goods faster, more accurately and at a lower cost, while maintaining high standards.

What is an example of automated production?

One of the most popular automated production systems used in modern manufacturing is industrial robots for tasks such as welding, painting, assembling, and packaging. These robots are programmed to perform specific tasks with high precision and accuracy.

What does it mean to automate production?

Automated production is a process of manufacturing finished products, such as consumer goods, without any human intervention. Production processes can either be fully automated, or with the use of cobot technology, parts of the production or manufacturing line can be replaced with automated robots.

How to verify automatic production line producer reliability?

Conduct virtual or on-site factory audits examining ISO certification validity, real-time production monitoring systems, and third-party quality reports. Cross-reference client testimonials for throughput consistency and after-sales support responsiveness.

What is the typical lead time for production samples?

Industry standard sample delivery ranges 15-45 days depending on complexity. Reputable suppliers provide project-managed sampling with documented testing protocols and iterative refinement options before full-scale production.