Automatic Stacking Machine Supplier

Top sponsor listing

Top sponsor listing

0

0

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/25

1/25

CN

CN

1/12

1/12

1/3

1/3

1/14

1/14

1/3

1/3

1/14

1/14

1/3

1/3

1/5

1/5

0

0

1/3

1/3

1/3

1/3

About automatic stacking machine supplier

Where to Find Automatic Stacking Machine Suppliers?

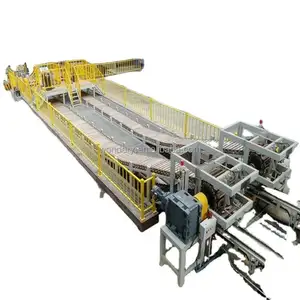

China remains the global epicenter for automatic stacking machine manufacturing, with key production hubs concentrated in Jiangsu, Hebei, and Shandong provinces. These regions host vertically integrated industrial ecosystems specializing in material handling automation, packaging systems, and woodworking machinery. Jiangsu’s Suzhou and Wuxi zones are known for high-precision robotic integration, leveraging proximity to semiconductor and electronics supply chains to enhance control system reliability. Hebei's packaging equipment corridor supports specialized carton and corrugated board stackers, while Shandong excels in heavy-duty timber and lumber stacking solutions.

The clustering effect enables suppliers to achieve economies of scale through co-located component manufacturers, CNC fabrication workshops, and logistics networks. Facilities typically operate 5,000–24,000+ m² production areas with monthly output capacities ranging from 20 to 100 units depending on complexity. This infrastructure supports lead times averaging 30–45 days for standard configurations, with localized sourcing reducing material costs by 15–25% compared to Western alternatives. Buyers benefit from flexible MOQs—often as low as one set—and rapid prototyping capabilities for customized automation workflows.

How to Choose Automatic Stacking Machine Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001 for quality management systems. For exports to Europe or North America, confirm CE marking compliance to meet safety, health, and environmental requirements. Request documentation on motor efficiency ratings (IEC 60034), structural load testing, and electrical panel design (IEC 60204-1). Robotics-integrated models should include functional safety assessments for emergency stops, light curtains, and PLC interlocks.

Production Capability Assessment

Evaluate core manufacturing competencies through the following indicators:

- Minimum factory area of 3,000m² to ensure scalable production capacity

- In-house engineering teams capable of customizing gripper types, conveyor interfaces, pallet formats, and HMI programming

- Integrated machining capabilities including CNC cutting, welding, and surface treatment processes

Cross-reference delivery performance (target ≥98%) with response time metrics (ideally ≤3 hours) to assess operational responsiveness and order prioritization.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services to mitigate financial risk until post-delivery inspection. Prioritize suppliers offering remote diagnostics, bilingual technical manuals, and video-assisted commissioning. Analyze reorder rates as a proxy for customer satisfaction—suppliers exceeding 60% indicate strong reliability and service consistency. Request references for field installations in your region to validate export experience and after-sales responsiveness.

What Are the Best Automatic Stacking Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|

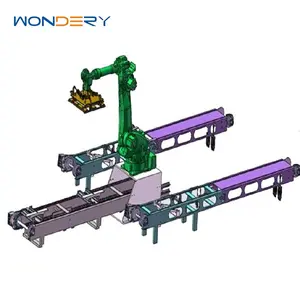

| Wuxi Wondery Industry Equipment Co., Ltd. | Industrial Furnaces, Metal Casting Machinery, Punching Machines | US $260,000+ | 100% | ≤3h | 60% | Color, material, size, logo, weight, ingot weight, packaging, label, graphic, capacity | Not specified |

| Suzhou YangBang Machinery Co., Ltd. | Palletizers, Packaging Lines, Filling & Sealing Machines | US $480,000+ | 100% | ≤3h | 72% | Carton size, speed, integration interface | $7,500–$8,200 |

| Jinan Alwi Machinery Co., Ltd. | Wood Saw Machines, Board Stackers, Forestry Equipment | US $40,000+ | 100% | ≤2h | 20% | Board length, thickness, stacking pattern | $2,000–$6,000 |

| Hebei Huazhu Carton Equipment Manufacturing Co., Ltd. | Corrugated Cardboard Stackers, Paper Processing Machinery | US $20,000+ | 100% | ≤3h | - | Stack height, feed rate, control system | $1,700–$6,000 |

| Luohe Ruihao Intelligent Equipment Co., Ltd. | Automatic Palletizers, Dry Mortar Machines, Packaging Robots | US $10,000+ | 100% | ≤2h | 25% | Pick-and-place logic, product type (bags, cases, cartons) | $6,500–$18,100 |

Performance Analysis

Suzhou YangBang leads in customer retention with a 72% reorder rate, indicating high satisfaction in packaging automation applications and consistent delivery of robotic palletizing systems. Wuxi Wondery demonstrates robust customization depth across multiple parameters, making it suitable for niche industrial applications requiring precise configuration. Jinan Alwi offers the most cost-competitive entry point ($2,000 minimum) for wood processing operations, supported by fast response times (≤2h), though its lower reorder rate suggests room for improvement in long-term client engagement. Hebei Huazhu targets mid-tier corrugated box producers with competitively priced stackers at $1,700 per unit, ideal for small-to-medium enterprises seeking basic automation. Luohe Ruihao commands premium pricing up to $18,100 for intelligent bag and case palletizers, reflecting advanced sensor integration and motion control capabilities. All listed suppliers maintain perfect on-time delivery records, underscoring reliable logistical execution despite varying company sizes and revenue scales.

FAQs

How to verify automatic stacking machine supplier reliability?

Cross-check ISO and CE certifications with official registries. Request factory audit reports or video walkthroughs showing CNC machining lines, assembly stations, and final testing procedures. Review transaction history for consistent order fulfillment and analyze customer feedback focusing on durability, ease of integration, and technical support responsiveness.

What is the typical lead time for automatic stacking machines?

Standard units are typically delivered within 30–45 days after order confirmation. Customized systems with PLC programming, special conveyors, or robot arms may require 50–70 days. Expedited production can reduce timelines by 10–15 days for urgent deployments, subject to supplier capacity.

Do suppliers offer customization options?

Yes, most suppliers provide extensive customization including load capacity (50–1,500 kg), stacking patterns (cross-bond, inline, rotated), conveyor interfaces, control panels (Siemens, Mitsubishi, Omron), and communication protocols (Modbus, Profibus, Ethernet/IP). High-end models support integration with warehouse management systems (WMS) and SCADA platforms.

What are common materials handled by these machines?

Automatic stacking machines process diverse materials including wood planks, corrugated cardboard boxes, cement bags, gypsum boards, metal ingots, plastic containers, and food/beverage cases. Material-specific grippers (vacuum, mechanical, belt-driven) and alignment systems must be matched to product characteristics such as weight, fragility, and dimensional variance.

Can suppliers handle global shipping and installation?

Established manufacturers manage international freight via FOB or CIF terms and provide disassembly/packaging suitable for containerized shipping. Many offer optional on-site installation supervision, operator training, and commissioning support—critical for complex robotic systems. Confirm whether electrical components are configured for local voltage (e.g., 380V/50Hz vs. 480V/60Hz) prior to shipment.