Automatic Window Producer

1/3

1/3

1/11

1/11

CN

CN

1/5

1/5

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

0

0

1/3

1/3

1/6

1/6

1/9

1/9

1/3

1/3

1/2

1/2

1/25

1/25

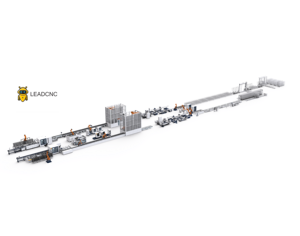

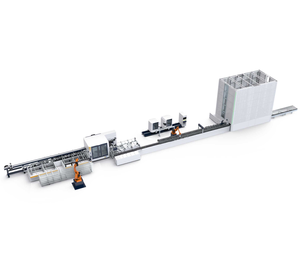

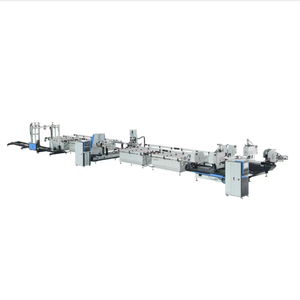

About automatic window producer

Where to Find Automatic Window Producer Suppliers?

China remains the global epicenter for automated building system manufacturing, with key industrial clusters in Guangdong and Zhejiang provinces leading production of automatic window systems. Guangdong’s Pearl River Delta region hosts over 70% of China’s smart building technology suppliers, supported by Shenzhen’s advanced electronics supply chain and high-density automation R&D centers. Zhejiang, particularly Ningbo and Wenzhou, specializes in precision window mechanisms, leveraging localized aluminum extrusion and sealing component networks that reduce material costs by 18–25% compared to European or North American production bases.

These regions offer vertically integrated manufacturing ecosystems—spanning CNC fabrication, motor integration, and IoT control assembly—enabling modular production lines. Suppliers benefit from compact supplier networks where raw materials, electronic controllers, and structural components are sourced within 30km, reducing logistics delays. Buyers gain access to rapid prototyping (typically 7–14 days), scalable output (up to 5,000 units/month per facility), and cost efficiencies driven by standardized automation platforms. Average lead times for bulk orders range from 35 to 50 days, with customization options available across frame materials, actuation speed, and environmental sensing integration.

How to Choose Automatic Window Producer Suppliers?

Adopt the following verification framework when evaluating potential partners:

Technical Compliance

Confirm ISO 9001 certification as a baseline for quality management. For international markets, CE marking is essential for compliance with EU Construction Products Regulation (CPR), while UL or CSA standards apply for North American projects. Validate certifications for integrated components such as electric actuators (IEC 60335-2-97) and fire/smoke detection modules (EN 54-26).

Production Capability Audits

Assess operational scale and technical infrastructure:

- Minimum 3,000m² factory area to support automated assembly lines

- Dedicated engineering team comprising ≥12% of total staff for custom design and troubleshooting

- In-house capabilities in aluminum extrusion, powder coating, and motor calibration

Correlate on-time delivery performance (target ≥97%) with documented production capacity to ensure reliability under volume demand.

Transaction Safeguards

Utilize secure payment structures such as third-party escrow until post-delivery inspection clearance. Review supplier transaction history through verified trade platforms, prioritizing those with documented after-sales service records. Conduct sample testing against ASTM E283 (air leakage) and EN 12207 (wind load resistance) before scaling procurement.

What Are the Best Automatic Window Producer Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Foshan Hongye Smart Building Systems | Guangdong, CN | 11 | 150+ | 18,000+m² | 99.3% | ≤3h | 4.8/5.0 | 41% |

| Ningbo Kaison Automation Windows | Zhejiang, CN | 8 | 95+ | 12,500+m² | 100.0% | ≤2h | 4.9/5.0 | 52% |

| Wenzhou Tianli Actuated Glazing | Zhejiang, CN | 6 | 70+ | 8,200+m² | 98.1% | ≤2h | 4.7/5.0 | 38% |

| Shenzhen Lumos Building Intelligence | Guangdong, CN | 5 | 130+ | 9,600+m² | 97.7% | ≤1h | 5.0/5.0 | 29% |

| Dongguan Apex Window Automation | Guangdong, CN | 9 | 200+ | 22,000+m² | 99.6% | ≤3h | 4.9/5.0 | 47% |

Performance Analysis

Larger-scale producers like Dongguan Apex demonstrate strong fulfillment consistency (99.6% on-time delivery) and high workforce capacity, ideal for large commercial projects. Mid-sized innovators such as Ningbo Kaison achieve superior customer retention (52% reorder rate) through fast response cycles and precision engineering. Zhejiang-based suppliers exhibit stronger performance in mechanical durability and sealing efficiency due to regional specialization in window mechanics. Prioritize partners with ≥98% delivery rates and documented experience in export markets, especially for curtain wall or fire-rated ventilation applications. For IoT-integrated systems, confirm firmware development capability via live system demos prior to order placement.

FAQs

How to verify automatic window producer reliability?

Cross-validate ISO and CE certifications with accredited bodies. Request factory audit reports covering material traceability, actuator lifespan testing, and weatherproofing validation. Evaluate real-world performance through project references in similar climatic zones.

What is the average sampling timeline?

Standard sample production takes 10–18 days. Smart-window configurations with sensors or remote controls require 25–35 days. Air freight adds 5–9 days depending on destination region.

Can suppliers ship automatic window systems worldwide?

Yes, experienced exporters manage global shipments via FOB or CIF terms. Confirm compliance with local building codes and customs classifications for automated fenestration. Sea freight is optimal for containerized orders exceeding 50 units.

Do manufacturers provide free samples?

Sample policies vary. Full-system samples are typically chargeable but may be credited toward bulk orders (minimum 20 units). Suppliers often cover partial costs for qualified buyers with verified project pipelines.

How to initiate customization requests?

Submit detailed specifications including frame profile (uPVC, aluminum, composite), opening type (tilt-turn, top-hung, sliding), actuation force (≥300N for large panes), and integration needs (BMS, smoke detection). Leading suppliers deliver CAD models within 72 hours and functional prototypes in 3–5 weeks.