Automation And Robotics In Manufacturing

CN

CN

About automation and robotics in manufacturing

Where to Find Automation and Robotics in Manufacturing Suppliers?

China's industrial automation sector is concentrated in the Pearl River Delta and Yangtze River Delta regions, with Guangdong and Jiangsu provinces emerging as core hubs for robotics manufacturing. Guangdong, home to Shenzhen and Dongguan, hosts over 70% of China’s collaborative robot (cobot) suppliers, supported by mature electronics and precision component ecosystems. Jiangsu’s Suzhou industrial zone specializes in high-precision motion control systems and end-effectors, benefiting from proximity to semiconductor and automotive assembly clusters.

These regions offer vertically integrated supply chains—encompassing servo motors, controllers, sensors, and structural components—within a 50km radius, reducing lead times by 25–40% compared to fragmented production networks. Suppliers leverage localized R&D centers and automated assembly lines to achieve scalable output, with average monthly production capacities ranging from 200 to 1,500 units depending on complexity. Buyers benefit from rapid prototyping capabilities, flexible batch sizing, and integration-ready solutions tailored for electronics, metalworking, and logistics applications.

How to Choose Automation and Robotics in Manufacturing Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Expertise and Product Range

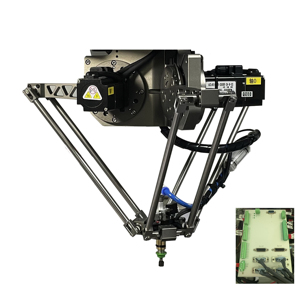

Prioritize suppliers offering articulated robots, collaborative robots (cobots), and end-of-arm tooling (e.g., electric grippers) with documented payload ranges (3kg–110kg) and repeatability tolerances (±0.02mm to ±0.1mm). Verify compatibility with common industrial protocols (Modbus, CANopen, EtherCAT) and integration support for CNC, welding, or palletizing workflows.

Production and Quality Assurance

Assess infrastructure maturity through key indicators:

- Minimum factory area exceeding 3,000m² for stable volume output

- In-house design and testing facilities for robotic kinematics and force feedback systems

- Compliance with ISO 9001 standards and product-level CE certification for export readiness

Cross-reference on-time delivery performance (target ≥95%) and response time (≤3 hours) as proxies for operational reliability.

Procurement and Risk Mitigation

Utilize secure transaction mechanisms such as escrow payment systems to align financial release with delivery milestones. Request sample units to validate performance against defined metrics—such as cycle time accuracy, grip force consistency, and software interface usability. For customized configurations, confirm firmware adaptability and technical documentation availability prior to full-scale ordering.

What Are the Best Automation and Robotics in Manufacturing Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order Value | Product Range |

|---|---|---|---|---|---|---|---|---|

| Guangdong Borunte Robot Technology Co., Ltd. | Guangdong, CN | Articulated Robots, Collaborative Robots, Electric Grippers | US $20,000+ | 66% | ≤3h | 100% | $999/set | 5 models (6-axis arms, flexible grippers) |

| SWJD LIMITED | Jiangsu, CN | Articulated Robots, Palletizers, Welding Robots | US $10,000+ | 100% | ≤3h | 66% | $5,999/set | 5 models (up to 30kg payload) |

| Shenzhen Era Automation Co., Ltd. | Guangdong, CN | Collaborative Robots, AGVs, Composite Systems | US $350,000+ | 100% | ≤2h | 50% | $3,600/set | 5 models (integrated AMR solutions) |

| Ae Robotics Co., Ltd. | Zhejiang, CN | Industrial Robots (Kawasaki, Fanuc, ABB replicas) | US $40,000+ | 100% | ≤4h | 20% | $8,500/set | 5 models (6-axis arms up to 110kg) |

| Changingtek Robotics Technology (Suzhou) Co., Ltd. | Jiangsu, CN | Electric Grippers, Servo Fingers, Cobot Accessories | US $6,000+ | 100% | ≤2h | 33% | $643/piece | 5 gripper variants (force-controlled) |

Performance Analysis

Shenzhen Era Automation stands out with the highest online revenue (US $350,000+) and fastest response time (≤2h), indicating strong market demand and operational responsiveness. SWJD LIMITED and Ae Robotics demonstrate perfect on-time delivery records (100%), making them reliable for time-sensitive deployments. Guangdong Borunte achieves a 100% reorder rate despite moderate delivery performance, suggesting high product satisfaction in niche applications like electronic assembly. Changingtek focuses on modular components with sub-$1,000 pricing, ideal for retrofitting existing robotic cells. Buyers seeking turnkey cobot systems should prioritize suppliers with integrated AGV or CNC coordination capabilities, while those requiring high-payload industrial arms should evaluate Ae Robotics’ Fanuc- and ABB-compatible models.

FAQs

How to verify automation and robotics supplier credibility?

Validate certifications (ISO 9001, CE) through official registries. Request test reports for critical parameters such as positioning accuracy, mean time between failures (MTBF), and overload endurance. Review transaction history, including reorder rates and dispute resolution outcomes, as indicators of long-term reliability.

What are typical MOQ and lead times?

Standard minimum order quantities start at 1 set or piece, with average lead times of 15–30 days post-payment confirmation. Complex configurations or bulk orders (≥10 units) may extend lead times to 45 days. Expedited builds are available from select suppliers within 7–10 days at a premium.

Can suppliers customize robots for specific applications?

Yes, most suppliers offer customization in color, labeling, firmware logic, and mechanical interfaces. Full OEM/ODM services—including custom payloads, reach extensions, and proprietary communication protocols—are available upon technical review and NDA agreement.

Do suppliers provide technical support and documentation?

Leading suppliers deliver comprehensive documentation (user manuals, API guides, CAD drawings) and remote troubleshooting support. Some offer on-site commissioning assistance or training programs for integration teams, particularly for large-volume or mission-critical installations.

Are samples available before bulk procurement?

Sample availability depends on product type. Basic grippers and low-payload arms can be sampled at partial cost recovery (30–70% of unit price). High-end robotic arms (>$10,000) typically require full payment for initial units, which may be credited toward future orders exceeding five units.