Automation Production System

Top sponsor listing

Top sponsor listing

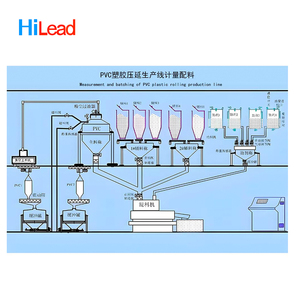

About automation production system

Where to Find Automation Production System Suppliers?

China remains the global epicenter for automation production system manufacturing, with key industrial hubs in Shandong, Guangdong, and Henan provinces driving innovation and scale. Shandong’s Qingdao region hosts integrated packaging and material handling equipment clusters, where suppliers benefit from proximity to steel and control system component manufacturers, reducing input costs by 15–20%. Guangdong’s Shenzhen and Foshan zones specialize in precision linear motion and robotic integration technologies, supported by dense electronics supply chains and advanced CNC fabrication networks.

These regional ecosystems enable vertically aligned production—from sheet metal processing to full-system assembly—within compact geographic radii. This integration supports rapid prototyping, shorter lead times (typically 30–45 days for customized systems), and scalability for both small-batch and high-volume orders. Buyers gain access to mature technical infrastructures, including in-house R&D departments, automated testing facilities, and export-compliant quality management frameworks, ensuring consistent delivery performance across complex automation projects.

How to Choose Automation Production System Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm ISO 9001 certification as a baseline for quality management. For international deployments, ensure compliance with CE or relevant regional safety standards. Request documentation on control system architecture (e.g., PLC brands, HMI interfaces), motor specifications, and software integration protocols. Validate engineering capacity through design submissions, 3D modeling capabilities, and prior project portfolios involving multi-axis automation or conveyor synchronization.

Production Infrastructure Assessment

Evaluate supplier facility maturity using these benchmarks:

- Minimum 3,000m² factory area for system-level assembly

- In-house engineering team capable of customizing control logic, sensor integration, and human-machine interfaces

- Proven experience with modular automation platforms (e.g., linear modules, articulated robots, batch control systems)

Cross-reference declared production capacity with on-time delivery rates (target ≥98%) and reorder frequency to assess reliability under volume pressure.

Customization and Transaction Safeguards

Require detailed proposals outlining material options (e.g., stainless steel, aluminum alloys), dimensional tolerances, load ratings, and interface compatibility. Insist on milestone-based payment structures with partial escrow protection until site acceptance testing is completed. Prioritize suppliers offering pre-shipment inspection reports, remote commissioning support, and post-installation technical follow-up.

What Are the Best Automation Production System Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Revenue Tier | Customization Scope |

|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Shandong, CN | Packaging Line (817) Conveyors (158) Sealing Machines (206) | 100.0% | ≤2h | 20% | US $1.3M+ | Material, size, control system, packaging layout |

| Shenzhen Jufeng Jingke Automation Technology Co., Ltd. | Guangdong, CN | Linear Robots (123) Linear Guides (104) | 100.0% | ≤1h | 22% | US $10K+ | Stroke length, motor type, guide rail configuration |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Henan, CN | Assembly Line (547) Metal Processing Line (18) | 100.0% | ≤8h | - | - | Full automotive and industrial assembly line design |

| Foshan City Excellent Guan Can Electromechanical Co., Ltd. | Guangdong, CN | Packaging Line (161) Articulated Robots (49) | 100.0% | ≤9h | - | - | Electronic control systems, batching logic, sensor integration |

| Huizhou Zhenji Automation Technology Co., Ltd. | Guangdong, CN | Assembly Line (97) Linear Guides (78) | 100.0% | ≤1h | 50% | US $10K+ | Curved conveyors, low-friction guides, custom ring diameters |

Performance Analysis

Qingdao Ausense leads in packaging automation volume with over 800 listed packaging line configurations, backed by strong revenue performance and broad customization options. Shenzhen Jufeng Jingke and Huizhou Zhenji stand out for responsiveness (≤1h average reply time) and high reorder rates (22% and 50%, respectively), indicating strong customer satisfaction in precision motion component supply. Zhengzhou Duoyuan specializes in large-scale automotive assembly systems with six-figure unit pricing, reflecting deep engineering integration capability. While some suppliers lack disclosed financial metrics, consistent 100% on-time delivery records across all five indicate robust production planning and export logistics execution. For mission-critical deployments, prioritize vendors with documented control system programming experience and proven integration with SCADA or MES environments.

FAQs

How to verify automation production system supplier reliability?

Audit quality management systems for ISO 9001 certification and request evidence of product testing, such as load cycle validation or electrical safety checks. Analyze historical transaction data, focusing on delivery consistency and post-sale technical support. Conduct virtual factory tours to confirm in-house machining, assembly, and testing capacities.

What is the typical lead time for customized automation systems?

Standard configurations ship within 20–30 days. Fully customized systems require 45–60 days, depending on complexity. Projects involving PLC programming, vision system integration, or non-standard mechanical designs may extend to 75 days. Prototypes are typically available within 3–4 weeks upon final specification approval.

Do suppliers support OEM branding and private labeling?

Yes, most suppliers offer OEM services including logo imprinting, custom color schemes, branded HMI interfaces, and proprietary software labeling. Minimum order quantities for branding vary but typically start at one unit for electronic labeling and five units for physical engraving or packaging customization.

What are common MOQ and pricing structures?

Minimum order quantities are frequently set at one unit for system-level products, though pricing decreases significantly at 5+ units. Unit prices range from $1,500 for basic control modules to over $80,000 for fully automated assembly lines. Bulk discounts of 10–15% apply for container-load orders (10+ systems).

How to initiate a customization request?

Submit detailed technical requirements including dimensions, throughput rate, load capacity, environmental conditions, power supply, and communication protocols (e.g., Modbus, EtherCAT). Reputable suppliers respond with feasibility assessments, 3D layouts, and control system schematics within 72 hours. Prototype development follows within three weeks after deposit confirmation.