Automation Robotics And Future Factories

CN

CN

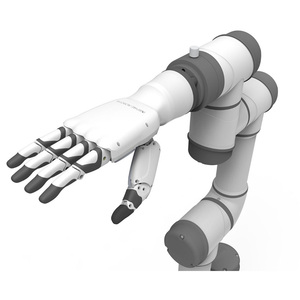

About automation robotics and future factories

Where to Find Automation Robotics and Future Factories Suppliers?

China remains a central hub for automation robotics manufacturing, with key supplier clusters concentrated in Fujian, Guangdong, and Zhejiang provinces. Xiamen and Guangzhou host advanced industrial ecosystems specializing in articulated robots, collaborative systems (cobots), and integrated smart factory solutions. These regions benefit from proximity to semiconductor, electronics, and automotive supply chains, enabling rapid deployment of automated assembly, welding, labeling, and material handling systems tailored for future-ready production environments.

Suppliers in these zones operate within vertically integrated networks that include precision machining, control system development, and robotic integration services. This infrastructure supports scalable production—from single-unit educational robot arms to full-line automated SMT and labeling systems—reducing lead times by up to 30% compared to decentralized models. Buyers gain access to mature technical ecosystems where firmware development, vision systems (CCD), and IoT-enabled monitoring are standard features across mid-to-high-end offerings.

How to Choose Automation Robotics and Future Factories Suppliers?

Effective supplier selection requires structured evaluation across three critical domains:

Technical Capability Verification

Confirm expertise in core robotic technologies: 6-axis articulation, payload capacity (ranging from 5kg to 16kg in sampled data), and integration readiness with CNC, AGVs, or soldering/welding modules. Prioritize suppliers offering CE compliance and ISO 9001-certified processes, particularly for deployments in EU or North American facilities. Request validation of motion precision, repeatability ratings, and cycle testing logs for high-utilization applications.

Production and R&D Infrastructure Assessment

Evaluate operational scale and innovation capacity through the following indicators:

- Facility size supporting dedicated R&D units and pilot testing lines

- In-house engineering teams capable of custom programming and PLC integration

- On-site prototyping capabilities for application-specific end-of-arm tooling

Cross-reference response times (as low as ≤1h) and on-time delivery performance (100% reported across multiple suppliers) as proxies for operational discipline and resource availability.

Transaction and Quality Assurance Protocols

Utilize secure payment frameworks such as escrow services to mitigate risk during initial procurement. Insist on pre-shipment inspections and functional testing—especially for fully automated lines priced above $65,000. Analyze reorder rates (<15% to 20%) and online transaction volume (up to US $40,000+) as indicators of market acceptance and post-sales support effectiveness. For customized integrations, verify packaging, labeling, and branding modification options prior to order finalization.

What Are the Best Automation Robotics and Future Factories Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Xiamen Device Technology Co., Ltd. | Fujian, CN | Articulated Robots, Collaborative Robots | $2,850–7,250 | 1 piece | Not specified | ≤4h | 100% | US $6,000+ |

| Xiamen Future Att Technology Co., Ltd. | Fujian, CN | SMT Machines, Smart Storage Systems | $65,000–390,000 | 1 set | 100% | ≤6h | Not specified | Not specified |

| Guangzhou Koza Robot Engineering Technology Co., Ltd. | Guangdong, CN | 6-Axis Robots, Laser Welders, Manipulators | $11,331–18,522.53 | 1 piece | 100% | ≤1h | Not specified | Not specified |

| Shenzhen Shengxinhuaye Environmental Protection Co., Ltd. | Guangdong, CN | Collaborative Robots, Industrial Arms | $3,488–8,888 | 1 set | 100% | ≤4h | <15% | US $20,000+ |

| Ae Robotics Co., Ltd. | Not specified | Cobots, CNC Integration, AGV Systems | $8,420–36,500 | 1 set | 100% | ≤4h | 20% | US $40,000+ |

Performance Analysis

Suppliers like Guangzhou Koza demonstrate strong technical responsiveness (≤1h average reply time) and focus on high-payload industrial arms, positioning them for demanding automation tasks. Xiamen-based firms specialize in complete smart factory lines, with system-level pricing reflecting integration complexity. Ae Robotics stands out in customization breadth, offering color, material, logo, and packaging modifications—critical for OEM integrators. Reorder rates suggest moderate customer retention outside top-tier service performers, indicating room for differentiation through after-sales support and software updates. Prioritize partners with documented delivery reliability and verifiable revenue activity when sourcing mission-critical robotic cells.

FAQs

How to verify automation robotics supplier credibility?

Validate certifications (ISO 9001, CE) through official registries. Request factory audit reports or video tours confirming CNC machining, assembly, and testing capabilities. Assess technical communication quality during inquiry stages as an indicator of integration support competence.

What is the typical lead time for robotic arm orders?

Standard configurations ship within 15–30 days. Customized cobots or integrated systems may require 45–60 days depending on software development and testing requirements. Confirm production scheduling before order placement.

Can suppliers provide global shipping for heavy automation systems?

Yes, experienced exporters manage international logistics via sea freight, particularly for large-scale installations. Clarify FOB/CIF terms, customs documentation, and import compliance for machinery in destination markets, especially for electrical safety and robotic safety standards (e.g., ISO 10218).

Do suppliers offer free samples or trial units?

Sample policies vary. Some suppliers waive fees for qualified bulk orders (e.g., 5+ units). Trial deployments of educational or entry-level robotic arms may be available at reduced cost. Full-scale automation lines typically require paid prototypes.

How extensive is customization for industrial robotics?

Leading suppliers support configuration adjustments including payload tuning, reach extension, gripper type, control interface (teach pendant/UI), and communication protocols (Modbus, Ethernet/IP). Full OEM branding and enclosure design changes are available upon request, subject to MOQ agreements.