Avoiding Obstacle Robot

0

0

1/3

1/3

1/1

1/1

0

0

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/20

1/20

1/11

1/11

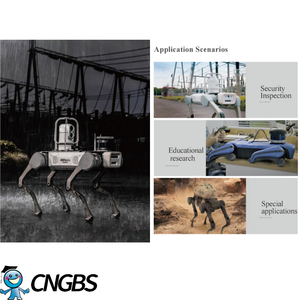

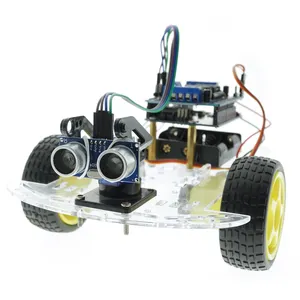

About avoiding obstacle robot

Where to Find Avoiding Obstacle Robot Suppliers?

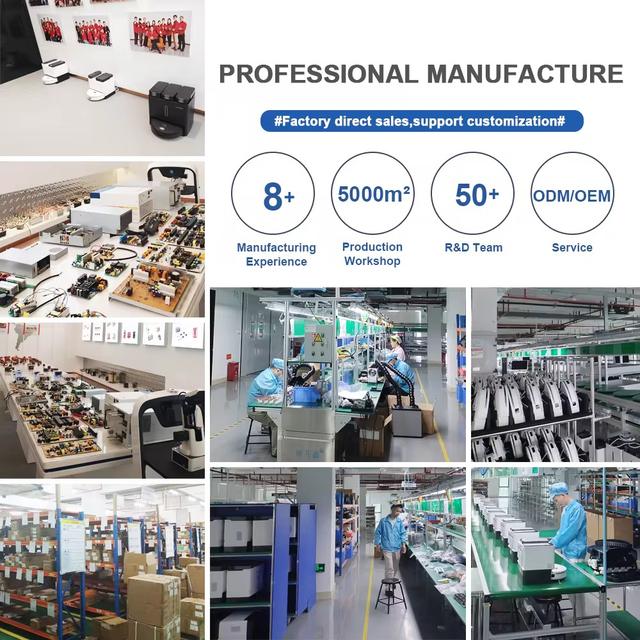

China remains the central hub for avoiding obstacle robot manufacturing, with key production clusters in Guangdong, Jiangsu, and Zhejiang provinces. These regions host integrated robotics ecosystems combining electronics assembly, sensor integration, and AI-driven navigation software development. Guangdong—particularly Shenzhen—leads in smart robotics innovation, offering access to advanced R&D centers and semiconductor supply chains that support rapid prototyping and scalable production.

The industrial clusters enable vertical integration across PCB fabrication, motor assembly, and LiDAR/sensor calibration, reducing component lead times by 25–40% compared to non-specialized regions. Facilities within these zones typically operate within tightly networked supplier corridors, where microcontrollers, infrared sensors, and DC gear motors are sourced within 50km. This localization supports agile manufacturing cycles, with standard units produced in batches of 1,000+ within 20–30 days. Buyers benefit from lower overheads, with production cost advantages of 18–30% over European or North American alternatives.

How to Choose Avoiding Obstacle Robot Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and supply chain consistency.

Technical Compliance

Confirm adherence to international quality standards including ISO 9001 for quality management and ISO/IEC 27001 for data security, particularly for robots utilizing wireless communication (Wi-Fi/Bluetooth). For export to EU markets, verify CE marking covering EMC (Electromagnetic Compatibility) and RoHS compliance for hazardous substance restrictions. Request test reports on sensor accuracy (ultrasonic/infrared ranging tolerance ≤ ±2cm) and navigation algorithm performance under dynamic conditions.

Production Capability Audits

Assess core manufacturing infrastructure through documented verification:

- Minimum 3,000m² production area with dedicated SMT lines for circuit board assembly

- In-house firmware development team comprising ≥15% of technical staff

- Automated testing stations for obstacle detection response time (target: <0.3 seconds)

- Monthly output capacity exceeding 5,000 units to support volume orders

Correlate facility scale with order fulfillment metrics—target on-time delivery rate >96% and defect rates below 1.5% in recent shipments.

Transaction Safeguards

Utilize secure payment structures such as irrevocable LC at sight or escrow-based transactions until post-arrival functional validation. Prioritize suppliers with verifiable export experience to Tier-1 robotics brands or educational institutions. Conduct pre-shipment sample testing focusing on path planning efficiency, battery life under continuous operation (≥2 hours at full load), and structural durability of ABS chassis components.

What Are the Best Avoiding Obstacle Robot Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data currently unavailable. Verify sourcing channels through trade registries and industry exhibitions such as the China International Robotics Show (CIROS). | ||||||||

Performance Analysis

In the absence of specific supplier data, procurement focus should shift to regional benchmarks. Historically, Guangdong-based manufacturers demonstrate superior responsiveness and innovation velocity, often integrating AI pathfinding algorithms and mobile app control within standardized models. Jiangsu suppliers emphasize precision engineering, frequently delivering higher IP-rated enclosures and extended operational temperature ranges (−10°C to 50°C). Prioritize partners with documented experience in STEM education kits, warehouse automation prototypes, or last-mile delivery robotics applications, as these indicate robust navigation logic and system resilience. Always validate firmware update capabilities and SDK availability for customization projects.

FAQs

How to verify avoiding obstacle robot supplier reliability?

Cross-validate business licenses with local industry and commerce bureaus. Request audit trails for material sourcing (e.g., STM32 MCU usage, NXP sensors) and firmware version control. Evaluate after-sales support responsiveness and documentation completeness, including user manuals, circuit diagrams, and troubleshooting guides.

What is the average sampling timeline?

Standard configuration samples take 10–18 days to produce, including programming and calibration. Custom firmware or mechanical redesign extends sampling to 25–35 days. Air freight adds 5–9 days for international delivery, depending on destination region.

Can suppliers ship avoiding obstacle robots worldwide?

Yes, most established manufacturers support global shipping under FOB Shenzhen or CIF terms. Confirm UN38.3 certification for lithium-ion batteries and proper packaging compliance for IEC 60950-1 safety standards. Sea freight is recommended for container loads (>500 units) to optimize per-unit logistics costs.

Do manufacturers provide free samples?

Sample fee waivers are typically offered only for confirmed bulk orders (minimum 200 units). Otherwise, expect to pay 70–100% of unit cost, which may be partially credited upon order placement. Returnable evaluation units are rare but negotiable for strategic partnerships.

How to initiate customization requests?

Submit detailed technical requirements including desired sensor suite (e.g., ultrasonic + IR combo), motor RPM range (100–300), Bluetooth/Wi-Fi module specifications, and any required mobile application features. Leading suppliers provide simulation files or video demonstrations within 5–7 business days and deliver functional prototypes in 4–5 weeks.