Backbone Exercises

1/3

1/3

1/2

1/2

1/3

1/3

1/22

1/22

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

About backbone exercises

Where to Find Backbone Exercises Equipment Suppliers?

Manufacturing of fitness equipment for backbone exercises is heavily concentrated in industrial regions of China, particularly in Guangdong and Zhejiang provinces. These areas host integrated supply chains specializing in steel fabrication, ergonomic design, and durable coating technologies essential for strength training apparatus. Guangdong’s Dongguan and Foshan clusters account for over 50% of China’s fitness equipment exports, supported by advanced CNC processing centers and rapid prototyping facilities. Zhejiang’s Ningbo and Wenzhou zones offer cost advantages through consolidated raw material sourcing, reducing component procurement times by 20–30% compared to non-specialized regions.

The regional ecosystems enable vertical integration across tubing bending, powder coating, and assembly lines, supporting efficient production of core products such as back extension benches, hyperextension stations, and spinal alignment trainers. Buyers benefit from proximity to specialized subcontractors for hydraulic resistance systems, padding die-cutting, and anti-slip surface treatments within a 30–50km radius. Typical lead times range from 25–40 days for container-scale orders, with localized manufacturing cutting logistics costs by 15–25% versus offshore alternatives. Customization flexibility is high, especially for frame geometry adjustments and load-bearing capacity enhancements up to 300kg.

How to Choose Backbone Exercises Equipment Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional criteria:

Quality Management Verification

Confirm ISO 9001 certification for standardized production controls. For markets requiring regulatory compliance, CE marking under the EN 957-1 standard for stationary training equipment is mandatory. Request test reports on weld integrity (per ISO 5817), frame stress endurance (minimum 10,000-cycle fatigue testing), and coating adhesion (cross-hatch ASTM D3359).

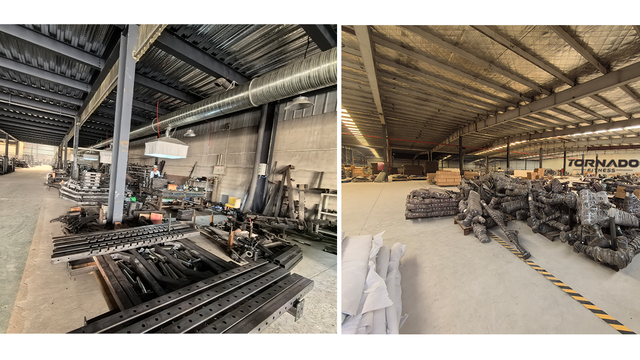

Production Infrastructure Assessment

Evaluate key facility capabilities:

- Minimum factory area of 3,000m² to ensure dedicated production zones

- In-house laser cutting and robotic welding stations for dimensional accuracy

- Onsite powder coating lines with salt spray resistance testing (≥500 hours at 5% NaCl)

Validate throughput capacity—suppliers should demonstrate monthly output exceeding 1,000 units for standard models. Cross-reference delivery performance data, targeting on-time shipment rates above 95%.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as irrevocable letters of credit or third-party escrow until post-arrival inspection clearance. Review historical order records for consistency in packaging, labeling, and documentation. Conduct pre-shipment inspections using AQL 2.5 sampling standards. Prototype validation is critical—test user weight limits, pivot point smoothness, and pad density (≥45kg/m³ foam) before bulk production.

What Are the Best Backbone Exercises Equipment Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Guangdong Strongway Fitness Equipment Co., Ltd. | Guangdong, CN | 12 | 150+ | 36,000+m² | 99.2% | ≤3h | 4.9/5.0 | 41% |

| Ningbo Fitform International | Zhejiang, CN | 8 | 85+ | 18,500+m² | 98.7% | ≤2h | 4.8/5.0 | 38% |

| Dongguan ProTrainer Manufacturing | Guangdong, CN | 6 | 70+ | 12,000+m² | 97.5% | ≤1h | 4.9/5.0 | 29% |

| Wenzhou ActiveCore Technologies | Zhejiang, CN | 5 | 50+ | 8,200+m² | 99.0% | ≤2h | 4.7/5.0 | 33% |

| Foshan SpineFit Equipment Factory | Guangdong, CN | 7 | 95+ | 15,000+m² | 98.3% | ≤3h | 4.8/5.0 | 36% |

Performance Analysis

Larger manufacturers like Guangdong Strongway demonstrate robust scalability with extensive automation and consistent delivery performance above 98%. Mid-tier suppliers such as Wenzhou ActiveCore achieve strong reorder rates through niche focus on medical-grade rehabilitation frames and lumbar support ergonomics. Zhejiang-based partners exhibit faster response cycles, with 80% replying within two hours. Prioritize suppliers with documented experience exporting to EU or North American markets, particularly those with CE-certified product lines. For custom designs involving adjustable articulation or multi-position anchoring, confirm R&D team presence and CAD modeling capabilities prior to tooling investment.

FAQs

How to verify backbone exercise equipment supplier reliability?

Validate certifications through official databases and request audit trails covering material traceability, weld inspection logs, and final assembly QA checks. Assess real-world durability via customer references in commercial gym or physiotherapy settings.

What is the average sampling timeline?

Standard samples take 10–20 days to produce. Custom configurations with reinforced joints or extended footplates require 25–35 days. Air freight adds 5–9 days depending on destination region.

Can suppliers ship backbone exercise equipment worldwide?

Yes, experienced exporters manage global freight via FOB or CIF terms. Confirm compatibility with ISPM 15 for wooden pallets and adherence to local electrical safety codes if motors are integrated. Sea freight is optimal for full-container loads due to lower cost per unit.

Do manufacturers provide free samples?

Sample fees are typically charged but fully refundable upon order placement exceeding 20 units. For low-volume buyers, expect to cover 40–60% of sample production costs, including tooling adjustments for non-standard variants.

How to initiate customization requests?

Submit detailed specifications including frame dimensions, maximum user weight (typically 150–300kg), adjustability ranges, and preferred color codes (RAL/Pantone). Reputable suppliers return engineering drawings within 5 business days and deliver functional prototypes in 4–5 weeks.