Bar Plot

1/3

1/3

1/1

1/1

1/3

1/3

1/27

1/27

1/3

1/3

1/3

1/3

1/3

1/3

1/16

1/16

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/12

1/12

1/2

1/2

1/3

1/3

0

0

CN

CN

1/29

1/29

1/3

1/3

1/3

1/3

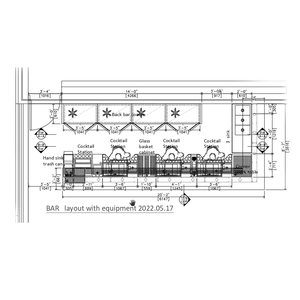

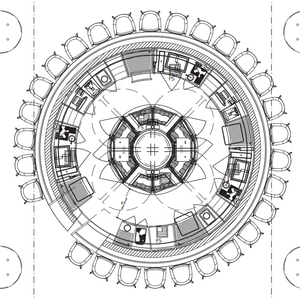

About bar plot

Where to Find Bar Plot Suppliers?

Global bar plot manufacturing is primarily concentrated in industrial hubs across China, with key production clusters in Guangdong and Zhejiang provinces. Guangdong, particularly the Pearl River Delta region, hosts over 70% of Asia’s metal fabrication and precision engineering facilities, supported by advanced CNC machining networks and rapid prototyping infrastructure. Zhejiang’s Ningbo and Wenzhou zones specialize in modular steel structures, leveraging proximity to raw material suppliers and deep-sea ports for efficient export logistics.

These regions benefit from vertically integrated supply chains—encompassing tube bending, welding automation, powder coating, and assembly lines—reducing component procurement lead times by up to 40%. Manufacturers typically operate within compact industrial ecosystems where subcontractors for stainless steel tubing, fasteners, and anti-slip surfaces are located within 30km. This enables standard order fulfillment in 25–35 days, with production costs 18–25% lower than equivalent EU or North American fabricators due to localized sourcing and energy-efficient processing techniques.

How to Choose Bar Plot Suppliers?

Implement structured evaluation criteria when selecting suppliers:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for consistent production control. For commercial installations in regulated environments (e.g., stadiums, transportation hubs), verify compliance with structural safety standards such as EN 1090 (Europe) or AISC 360 (North America). Request test reports for load-bearing capacity (typically rated at 1,500–2,000kg per linear meter) and corrosion resistance, especially for outdoor applications.

Production Infrastructure Assessment

Evaluate core operational capabilities through documented evidence:

- Minimum factory footprint of 3,000m² to ensure batch processing capacity

- In-house laser cutting and robotic welding stations for dimensional accuracy

- Surface treatment facilities including electrophoretic coating or hot-dip galvanization

Correlate facility size with order scalability and on-time delivery performance (target ≥97%).

Procurement Risk Mitigation

Utilize secure payment mechanisms such as letter of credit or third-party escrow until post-arrival inspection clearance. Review transaction history via verified trade platforms, prioritizing suppliers with documented after-sales service records. Conduct pre-shipment inspections to validate weld integrity, alignment tolerances (±1mm), and finish consistency. Sample testing is recommended—assess impact resilience and footplate stability under simulated use conditions before full-scale ordering.

What Are the Best Bar Plot Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

In the absence of specific supplier data, procurement focus should remain on regional advantages and technical verification protocols. Historically, long-established manufacturers in Guangdong demonstrate higher investment in automated production lines, yielding tighter tolerances and faster turnaround for bulk orders. Meanwhile, Zhejiang-based fabricators often offer greater flexibility in customization, including variable heights (900–1,100mm), curved configurations, and dual-rail designs. Prioritize partners with documented experience in large-volume public projects or international exports, confirmed through project portfolios and shipping records. For custom deployments, require CAD drawings and material certifications prior to production launch.

FAQs

How to verify bar plot supplier reliability?

Validate quality systems by cross-referencing ISO certificates with issuing bodies. Request audit trails covering raw material traceability (e.g., SS304/SS316 grade documentation), welding procedure specifications (WPS), and non-destructive testing (NDT) results. Assess real-world performance through client references, focusing on durability after 12+ months of continuous use.

What is the average sampling timeline?

Standard sample production takes 10–18 days, depending on complexity. Custom finishes (powder-coated colors, engraved identifiers) or non-standard dimensions may extend this to 25 days. Add 5–9 days for international air freight delivery.

Can suppliers ship bar plots worldwide?

Yes, most established manufacturers support global distribution. Confirm Incoterms (FOB, CIF, DDP) and packaging standards—bar plots are typically crated or bundled with protective corner caps to prevent transit damage. Sea freight is optimal for containerized orders exceeding 50 units.

Do manufacturers provide free samples?

Sample policies vary. Full-section samples are often charged at 40–60% of unit cost, refundable against future orders above negotiated thresholds (e.g., 20+ units). Some suppliers offer partial subsidies for qualified buyers with proven project timelines.

How to initiate customization requests?

Submit detailed technical requirements including mounting type (surface-fixed, recessed, or freestanding), tube diameter (commonly 38–50mm), spacing (≤110mm gap for child safety compliance), and finish type. Reputable suppliers provide engineering drawings within 48 hours and prototype units within 3–5 weeks for approval.