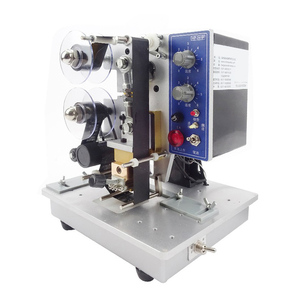

Batch And Date Printing Machine

About batch and date printing machine

Where to Find Batch and Date Printing Machine Suppliers?

China remains the central hub for batch and date printing machine manufacturing, with key production clusters in Guangdong, Hubei, and Liaoning provinces. These regions host vertically integrated supply chains specializing in industrial coding and marking equipment, leveraging localized access to precision components, inkjet technology R&D centers, and automated assembly lines. Guangzhou and Shenzhen serve as innovation hotspots for smart coding systems, integrating IoT-enabled printers with real-time data tracking. Wuhan and Shenyang contribute strong engineering bases focused on cost-efficient thermal inkjet (TIJ) and continuous inkjet (CIJ) solutions tailored for food, pharmaceutical, and packaging industries.

The concentration of technical suppliers within 50km radii enables rapid prototyping and scalable production. Manufacturers benefit from mature ecosystems encompassing nozzle fabrication, ink formulation, control software development, and conveyor integration. This localization reduces lead times by 20–30% compared to offshore alternatives and supports flexible configurations—from handheld coders to fully automatic inline systems. Average production capacity among mid-tier suppliers ranges from 300–800 units per month, with standard delivery windows between 15–30 days for non-customized orders.

How to Choose Batch and Date Printing Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compatibility and transactional reliability:

Technical Compliance & Output Quality

Verify that machines support required print methods (TIJ, CIJ, or thermal transfer) and deliver minimum resolution of 300 dpi for legible batch/date codes. Confirm compatibility with substrates such as PET, glass, metal, and laminated films. For regulated sectors like pharma, demand compliance with FDA, CE, and RoHS standards. Evaluate ink performance—water-resistant, UV-stable, or fast-drying formulations—as a critical factor in operational durability.

Production Capability Assessment

Assess supplier infrastructure using these benchmarks:

- Minimum factory area exceeding 2,000m² for stable output

- In-house engineering teams capable of custom firmware, language integration, and PLC controls

- On-site testing facilities for print adhesion, speed calibration (up to 120m/min), and environmental resilience

Cross-reference listed product portfolios with online revenue indicators and reorder rates to validate market acceptance and after-sales service effectiveness.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party payment protection and documented quality assurance protocols. Analyze response times (target ≤5 hours) and on-time delivery rates (preferably ≥95%) as proxies for operational responsiveness. Ensure technical support includes remote diagnostics, multilingual manuals, and spare parts availability. Request sample prints or video demonstrations before bulk ordering to verify font clarity, code positioning accuracy, and integration feasibility with existing production lines.

What Are the Best Batch and Date Printing Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | Inkjet Printers (241) | US $40,000+ | 96% | ≤3h | <15% | Limited |

| Wuhan Xiantong Technology Co., Ltd. | Hubei, CN | Inkjet Printers (88) | US $160,000+ | 100% | ≤5h | 21% | Moderate |

| Maersky Logo Technology (Guangzhou) Co., Ltd. | Guangdong, CN | Coding Machines (52) | US $200,000+ | 100% | ≤2h | 18% | Extensive |

| Shenzhen Yungchia Robot Technology Co., Ltd. | Guangdong, CN | Marking Printers (43+) | US $40,000+ | 87% | ≤9h | 26% | Highly Customizable |

| Shenyang Faith Technology Co., Ltd. | Liaoning, CN | Inkjet Printers (88+) | US $710,000+ | 97% | ≤1h | 22% | Comprehensive |

Performance Analysis

Shenyang Faith Technology leads in transaction volume and responsiveness, combining sub-1-hour replies with high customization depth across print height, ink type, and integration options. Maersky Logo Technology stands out for extensive configurability—including conveyor compatibility, multilingual interfaces, and UV-resistant inks—supported by a robust 100% on-time delivery record. Wuhan Xiantong demonstrates strong market retention (21% reorder rate) with reliable CIJ and TIJ platforms suitable for medium-scale producers. While Shenzhen Yungchia offers broad customization, its 87% delivery performance indicates potential fulfillment risks under peak demand. Buyers seeking standardized, high-speed coders should prioritize suppliers with dedicated R&D teams and proven export experience to North America and Europe.

FAQs

What is the typical MOQ for batch and date printing machines?

Most suppliers list a minimum order quantity (MOQ) of 1 set or piece, enabling low-volume procurement for testing and small production runs. Volume discounts typically apply at 5+ units, especially for OEM/ODM arrangements.

How long does customization take?

Lead time for customized models ranges from 20–35 days, depending on complexity. Modifications involving software interfaces, print resolution upgrades, or integration with conveyors require additional validation steps. Standard models ship within 15 days after order confirmation.

Do suppliers offer technical documentation and certifications?

Reputable manufacturers provide CE, RoHS, and ISO 9001-related documentation upon request. Firmware compliance, electrical safety reports, and material traceability records are essential for import clearance in regulated markets.

Can these machines print 2D codes and variable data?

Yes, advanced models support DataMatrix, QR codes, and dynamic serialization via Ethernet or USB connectivity. Ensure controllers are compatible with factory MES systems for real-time data synchronization.

What are common ink types used in these printers?

Standard inks include water-based, solvent, and UV-curable formulations. Selection depends on substrate porosity, environmental exposure, and regulatory requirements. Fast-dry and anti-smudge inks are recommended for high-speed bottling lines.