Batch Type Of Production

About batch type of production

Where to Find Batch Type of Production Equipment Suppliers?

China remains the global epicenter for batch-type production equipment manufacturing, with key industrial hubs in Henan and Shandong provinces driving innovation and scale. Henan’s Zhengzhou region hosts a dense cluster of machinery developers specializing in automated batching systems, supported by integrated logistics networks that streamline export operations. Shandong’s machinery corridor—centered around Jinan and Qingdao—leverages proximity to steel and heavy fabrication zones, enabling 15–20% cost efficiencies in structural components compared to international competitors.

These regions feature vertically aligned supply ecosystems where raw material processing, CNC fabrication, control system integration, and final assembly occur within compact geographic radii. This localization reduces lead times for standard units to 30–45 days and supports rapid prototyping for customized configurations. Buyers benefit from scalable production capacity, with facilities routinely handling orders from single sets to full turnkey lines. The concentration of technical labor and component suppliers enhances responsiveness and flexibility for both low- and high-volume procurement strategies.

How to Choose Batch Type of Production Equipment Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Technical Compliance and Certification

Verify ISO 9001 certification as a baseline indicator of quality management. For markets in Europe or North America, ensure CE marking compliance to meet safety and regulatory standards. Request documentation on electrical control systems (e.g., Siemens or Schneider PLCs), structural load testing, and material traceability reports, particularly for concrete and rubber processing machinery.

Production Capacity and Infrastructure

Assess operational scale through verifiable metrics:

- Minimum factory footprint of 5,000m² to support dedicated assembly lines

- In-house engineering teams capable of customizing batching logic, feed systems, and automation interfaces

- Integrated capabilities in welding, machining, and control panel fabrication

Correlate facility size with on-time delivery performance—suppliers maintaining ≥95% fulfillment rates typically demonstrate robust workflow management.

Transaction Security and After-Sales Support

Utilize secure payment mechanisms such as escrow services to mitigate risk until equipment verification is completed. Prioritize suppliers with documented service histories, including remote diagnostics, commissioning assistance, and spare parts availability. Review reorder rates as an indirect measure of post-delivery satisfaction; rates exceeding 60% suggest reliable performance and support.

What Are the Leading Batch Type of Production Equipment Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Key Product Range (USD) |

|---|---|---|---|---|---|---|---|---|

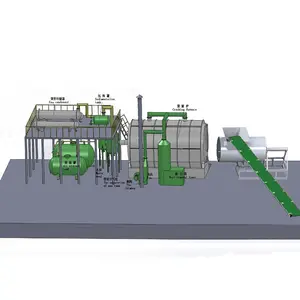

| Henan Doing IMT Co., Ltd. | Henan, CN | Rubber Pyrolysis Machines, Oil Pressers, Food Processing Lines | US $120,000+ | 100% | ≤4h | 100% | Yes | $18,000 – $78,000 |

| Shandong Cad Industry Machinery Equipment Co., Ltd. | Shandong, CN | Concrete Batch Plants, Asphalt Mixing Systems | US $670,000+ | 100% | ≤1h | 60% | Yes | $9,999 – $50,000 |

| Pacific Machinery Technology (Shandong) Co., Limited | Shandong, CN | Concrete Mixers, Batching Systems, Control Panels | US $620,000+ | 100% | ≤3h | 100% | Yes | $8,000 – $42,000 |

| JJEM TRADING | - | Concrete Batching Plants, Crushers, Mine Mills | Data Unavailable | Not Reported | ≤4h | Not Reported | Limited | $15,000 – $65,000 |

| Zhengzhou Shanghe Construction Machinery Co., Ltd. | Henan, CN | Concrete Batch Plants, Mixers, Pumps | US $1,000+ | 100% | ≤2h | <15% | Yes | $1,999 – $18,441 |

Performance Analysis

Henan Doing IMT and Pacific Machinery stand out with 100% reorder rates, indicating strong customer retention likely driven by consistent quality and after-sales reliability. Shandong Cad demonstrates superior responsiveness (≤1h average reply time) and high transaction volume, reflecting mature operational infrastructure. Zhengzhou Shanghe offers the most competitive pricing, with entry-level systems starting under $2,000, though its sub-15% reorder rate suggests potential limitations in long-term client satisfaction. JJEM TRADING lacks verified performance metrics, introducing higher due diligence requirements for risk-sensitive buyers.

FAQs

How to verify batch production equipment supplier credibility?

Cross-validate certifications with issuing bodies and request third-party audit summaries covering design validation, weld integrity, and control system functionality. Analyze customer feedback focusing on machine uptime, calibration accuracy, and technical support responsiveness.

What is the typical lead time for batch-type production systems?

Standard models are generally delivered within 30–45 days after order confirmation. Customized systems involving PLC programming or unique material handling integrations may require 60–75 days, depending on complexity.

Are customization options available for batching equipment?

Yes, leading suppliers offer configuration adjustments including batch size, feeding mechanism type (belt, screw, hopper), automation level (manual, semi-auto, fully automatic), and integration with upstream/downstream processes. Technical drawings and control schematics are typically provided for approval prior to production.

What are common MOQs and pricing structures?

Most suppliers list a minimum order quantity of 1 set, facilitating pilot procurement. Pricing varies significantly by application: waste tire pyrolysis systems range from $18,000–$78,000, while concrete batching plants span $8,000–$65,000 based on capacity and mobility features.

Can suppliers manage international shipping and customs clearance?

Established exporters provide FOB, CIF, and DAP shipping terms and assist with documentation for import compliance. Confirm inclusion of packing lists, certificates of origin, and CE/ISO compliance files to avoid port delays. Sea freight is standard for full-container loads due to equipment weight and dimensional constraints.