Best Cpu Build For Gaming

Top sponsor listing

Top sponsor listing

1/3

1/3

1/22

1/22

1/3

1/3

1/1

1/1

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About best cpu build for gaming

Where to Find CPU Build for Gaming Suppliers?

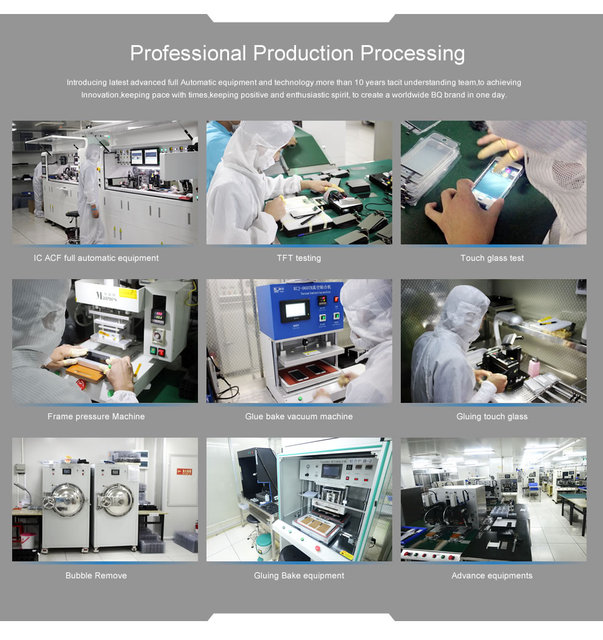

The global market for high-performance gaming CPU builds is primarily driven by specialized system integrators and component manufacturers concentrated in East Asia, particularly China, Taiwan, and South Korea. These regions host the majority of semiconductor fabrication facilities and advanced electronics assembly lines, enabling rapid prototyping and scalable production of custom gaming systems. Major technology hubs such as Shenzhen and Shanghai offer integrated supply chains where motherboard, CPU, GPU, cooling, and power component suppliers operate in close proximity, reducing integration complexity and logistics overhead.

These industrial ecosystems support both OEM/ODM configurations and fully customized builds, with many suppliers offering turnkey solutions that include BIOS optimization, thermal tuning, and pre-installed operating systems. Buyers benefit from vertical integration across memory modules, voltage regulation, and PCB manufacturing, allowing for precise performance calibration. Typical advantages include lead times of 20–35 days for batch orders, cost efficiencies of 15–25% compared to Western-assembled units, and flexibility in configuration scaling from mid-tier to enthusiast-grade components.

How to Choose CPU Build for Gaming Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and operational consistency:

Technical Compliance

Confirm adherence to international standards including IPC-A-610 for electronic assembly quality and JEDEC specifications for memory and thermal performance. For export markets, verify compatibility with regional power regulations (e.g., UL certification for North America, CE for Europe). Request validation documentation for CPU stress testing under sustained load (e.g., Prime95, AIDA64) and thermal throttling thresholds.

Production Capability Audits

Assess supplier infrastructure through verifiable benchmarks:

- Minimum 2,000m² cleanroom assembly area for ESD-safe operations

- Dedicated R&D team focused on overclocking stability and multi-GPU/CPU configurations

- In-house diagnostic stations with automated burn-in testing (minimum 72-hour cycles)

Correlate facility scale with on-time delivery performance (target >96%) and warranty claim rates (ideally <3%).

Transaction Safeguards

Utilize escrow-based payment terms until post-delivery validation is completed. Review transaction history via verified procurement channels, prioritizing suppliers with documented after-sales service agreements and firmware update support. Pre-shipment sample evaluation is critical—benchmark system performance against standardized metrics such as Cinebench R23 (multi-core), PassMark CPU scores, and thermal output under full load before approving volume orders.

What Are the Best CPU Build for Gaming Suppliers?

No supplier data available for analysis at this time.

Performance Analysis

In the absence of specific supplier profiles, buyers should focus on identifying partners with proven experience in assembling high-TDP processors (e.g., Intel Core i9, AMD Ryzen 9 series), advanced cooling integration (AIO liquid or phase-change systems), and UEFI-level customization capabilities. Preference should be given to suppliers who provide detailed build logs, component traceability, and compatibility matrices for DDR5, PCIe 5.0, and next-generation storage interfaces. Video walkthroughs of assembly workflows and real-time monitoring of stress-test results can serve as key indicators of technical maturity.

FAQs

How to verify gaming CPU build supplier reliability?

Cross-reference technical certifications with issuing bodies. Obtain third-party inspection reports covering assembly processes, component sourcing authenticity (e.g., genuine vs. remarketed CPUs), and long-term durability testing. Evaluate customer feedback on system stability, driver compatibility, and post-warranty support responsiveness.

What is the average sampling timeline?

Standard sample builds require 10–18 days for configuration, assembly, and burn-in testing. Complex setups involving water-cooled multi-CPU platforms or custom BIOS modifications may extend to 25 days. International air freight adds 5–9 days depending on destination region.

Can suppliers ship gaming CPU builds worldwide?

Yes, experienced integrators manage global logistics with appropriate packaging for shock-sensitive components. Confirm Incoterms (FOB, DDP) and compliance with import regulations related to electronic equipment in target markets. Sea freight is viable for containerized bulk shipments but increases transit risk for high-value units.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to minimum order quantities (typically 10+ units). Otherwise, expect to cover 40–60% of total build cost, which may be credited toward future orders.

How to initiate customization requests?

Submit detailed technical requirements including processor model, RAM capacity and speed, cooling type, case form factor, and software image preferences. Leading suppliers respond with bill-of-materials (BOM), 3D layout diagrams, and performance projections within 72 hours, followed by prototype availability in 3–4 weeks.