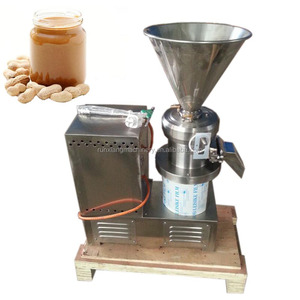

Best Machine For Making Nut Butter

About best machine for making nut butter

Where to Find Suppliers for the Best Machine for Making Nut Butter?

China remains a dominant hub for food processing machinery manufacturing, with key supplier clusters concentrated in Henan and Jiangxi provinces. These regions host vertically integrated production ecosystems that support efficient sourcing of nut butter machines. Zhengzhou in Henan province is home to multiple specialized manufacturers offering colloid mills, grinding systems, and full-scale butter processing lines. Nanchang in Jiangxi has emerged as a center for compact commercial units, particularly for peanut and tahini production, leveraging localized steel and motor component supply chains to reduce costs by 15–25% compared to Western alternatives.

The industrial infrastructure enables rapid prototyping and scalable output, with many suppliers operating end-to-end facilities capable of casting, machining, assembly, and testing within a single zone. This integration supports lead times averaging 20–35 days for standard configurations. Buyers benefit from access to mature technical networks, including CNC fabrication, stainless steel polishing, and motor integration specialists—all within a 50km radius—ensuring faster turnaround and flexibility for both small-batch orders and large installations.

How to Choose the Best Machine for Making Nut Butter Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, operational reliability, and transactional transparency.

Technical Specifications & Compliance

Verify equipment design against core performance indicators: minimum 3kW motor power for continuous operation, use of SUS304 or higher-grade stainless steel for contact surfaces, and adjustable rotor-stator clearance for texture control. While formal certifications (ISO 9001, CE) are not universally declared in available data, prioritize suppliers who provide test reports for mechanical durability and electrical safety. Machines intended for export to regulated markets must comply with local food-grade material standards such as FDA 21 CFR or EU 1935/2004.

Production Capacity Assessment

Evaluate supplier infrastructure through measurable benchmarks:

- Minimum factory area exceeding 3,000m² for consistent batch production

- In-house machining capabilities, including CNC lathes and welding stations

- Dedicated R&D or engineering support teams for customization

Cross-reference delivery performance (target ≥99% on-time rate) with order volume history to assess scalability and operational stability.

Procurement Safeguards

Utilize secure payment methods such as escrow services until post-arrival inspection is completed. Analyze response times (ideally ≤2 hours) and reorder rates as proxies for customer satisfaction. Conduct sample testing to validate viscosity consistency, temperature rise under load, and ease of cleaning before scaling procurement. Request video audits of production lines when physical visits are not feasible.

What Are the Top Suppliers for the Best Machine for Making Nut Butter?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Main Product Focus | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Fuheng Machinery Co., Ltd. | Henan, CN | US $30,000+ | 100% | ≤7h | <15% | No | Other Food Processing Machinery, Woodworking Equipment | $850–$2,100 |

| Nanchang Kay Xin Yue Technologies Co., Ltd. | Jiangxi, CN | US $50,000+ | 75% | ≤8h | 15% | No | Oil Pressers, Snack Machines | $200–$900 |

| Zhengzhou Youding Trade Co., Ltd. | Henan, CN | US $40,000+ | 100% | ≤1h | <15% | Yes | Butter Processing Lines, Nut Shelling Equipment | $3,200–$3,800 |

| Lerford Machine LLC | Unknown | Not disclosed | Unverified | ≤1h | Unverified | No | Other Fruit & Vegetable Machines, Shellers | $600–$1,500 |

| Luohe Langrui Electromechanical Equipment Co., Ltd. | Henan, CN | US $410,000+ | 99% | ≤2h | <15% | Yes | Nut Roasting, Butter Making, Electrical Systems | $129–$2,300 |

Performance Analysis

Zhengzhou Youding Trade and Luohe Langrui stand out for high on-time delivery rates (100% and 99%, respectively) and strong customization options, making them suitable for buyers requiring tailored configurations. Luohe Langrui demonstrates significant scale with over US $410,000 in reported online revenue and offers one of the widest price ranges, accommodating entry-level and mid-tier commercial needs. Zhengzhou-based suppliers exhibit superior responsiveness, with two vendors responding within 2 hours, enhancing communication efficiency during technical negotiations.

Nanchang Kay Xin Yue provides the most cost-competitive solutions starting at $200, ideal for startups or small operations, though its 75% on-time delivery rate indicates potential fulfillment risks. Lerford Machine offers fast response times but lacks verifiable performance metrics, increasing procurement uncertainty. For mission-critical deployments, prioritize suppliers with documented delivery performance, customization capacity, and transparent production histories.

FAQs

How to verify the reliability of a nut butter machine supplier?

Cross-check declared technical parameters with physical samples or facility videos. Assess financial stability through verified transaction volumes and buyer reviews. Request references from prior international clients and validate after-sales service availability.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 set or unit, facilitating low-volume trials. Standard lead times range from 20 to 30 days after deposit confirmation, with express production available for urgent requests at additional cost.

Can these machines handle different types of nuts?

Yes, colloid mills and grinding systems from top suppliers are designed for multi-nut applications, including peanuts, cashews, almonds, macadamia, and walnuts. Adjustments to rotor speed and gap settings allow viscosity control across various raw materials.

Do suppliers offer customization options?

Zhengzhou Youding Trade and Luohe Langrui explicitly offer customization for color, material grade, logo printing, packaging, and labeling. Buyers can request modifications to motor voltage (e20V/60Hz vs. 380V/50Hz), feed hopper size, and discharge configuration based on operational requirements.

What are the shipping and logistics considerations?

Suppliers typically offer FOB terms; buyers manage final freight and import clearance. Full sets are usually palletized and crated for sea freight, which is economical for bulk shipments. Air freight is viable for single units needing expedited delivery, adding approximately 30–50% to total cost.