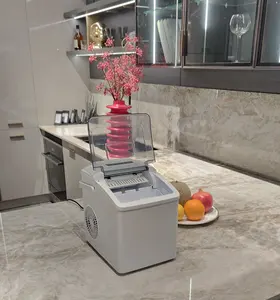

Best Portable Ice Cube Maker

Top sponsor listing

Top sponsor listing

1/26

1/26

1/24

1/24

1/21

1/21

1/25

1/25

1/10

1/10

1/31

1/31

1/19

1/19

About best portable ice cube maker

Where to Find Portable Ice Cube Maker Suppliers?

China leads global production of portable ice cube makers, with key manufacturing clusters in Jiangsu, Zhejiang, and Guangdong provinces. Jiangsu's Yancheng and Suzhou regions host vertically integrated facilities specializing in refrigeration systems and compact appliance assembly, enabling rapid scaling for export orders. Zhejiang’s Ningbo and Cixi zones focus on consumer-grade countertop models, leveraging proximity to polymer and compressor suppliers to reduce component lead times by 20–25%. Guangdong’s Shenzhen and Dongguan industrial bases emphasize innovation in DC-powered and handheld units, supported by dense electronics supply chains.

These regional ecosystems provide access to end-to-end production—from injection molding and sheet metal fabrication to final testing—within tightly coordinated supplier networks. Buyers benefit from streamlined logistics, with average factory-to-port transit under 48 hours. The concentration of engineering talent and tier-1 subcontractors allows for MOQs as low as 100 units and customization cycles of 15–20 days for modified designs. Average unit costs range from $33 to $90, with commercial-grade models exceeding $700, reflecting material quality, cooling method, and output capacity differences.

How to Choose Portable Ice Cube Maker Suppliers?

Apply these evaluation criteria to ensure reliable sourcing outcomes:

Technical and Quality Compliance

Confirm adherence to international safety and performance standards, including CE, RoHS, and UL certifications where applicable. For refrigerant-based models, verify use of environmentally compliant coolants (e.g., R600a) and compliance with local energy efficiency regulations. Request test reports for compressor lifespan (minimum 8,000 hours), cooling cycle consistency, and condensation management.

Production Capacity Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum monthly output capacity of 5,000 units for stable inventory fulfillment

- In-house capabilities in plastic molding, sheet metal processing, refrigerant charging, and final assembly

- Dedicated quality control line with leak testing, electrical safety checks, and load validation

Cross-reference on-time delivery rates (target ≥98%) and reorder rates (<15% indicates broad market competitiveness) to assess operational reliability.

Customization and Transaction Security

Prioritize suppliers offering configurable options in size, color, plug type, voltage (110V/220V), refrigerant, and branding (logo, packaging). Ensure secure transaction protocols via verified payment escrow and documented dispute resolution. Conduct sample testing to validate ice clarity, cycle time (ideally ≤6 minutes per batch), and noise levels (≤45 dB). Use platform-backed trade assurances where available to mitigate fulfillment risk.

What Are the Best Portable Ice Cube Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Key Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Eternity Import & Export Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | US $50,000+ | 100.0% | ≤2h | <15% | Color, size, logo, packaging, refrigerant, compressor, plug, power, material | 1–2 sets |

| Xiamen Sunford Industry Trade Co., Ltd. | Xiamen, CN | Multispecialty Supplier | US $290,000+ | 100.0% | ≤5h | <15% | Color, size, logo, packaging, material, graphic | 200 pieces |

| Cixi City Weisidun Environmental Protection Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $10,000+ | 100.0% | ≤4h | <15% | Color, material, size, logo, packaging, label, graphic | 2 pieces |

| Shenzhen Aurotech Technology Co., Ltd. | Guangdong, CN | — | US $130,000+ | 100.0% | ≤2h | 15% | Size, voltage, design, refrigerant, logo, packaging | 10–500 pieces |

Performance Analysis

Jiangsu Eternity demonstrates strong technical flexibility with extensive customization across cooling systems, compressors, and electrical specifications, making it ideal for branded or region-specific deployments. Xiamen Sunford leads in revenue volume and scalability, supporting large-volume contracts with consistent output and moderate MOQs. Cixi Weisidun offers the lowest entry MOQ (2 pieces), advantageous for product sampling and niche market testing. Shenzhen Aurotech specializes in innovative formats—including 12V DC and handheld models—catering to outdoor and mobile applications. All top suppliers maintain 100% on-time delivery, indicating robust production planning and export experience. Prioritize partners with ≤4-hour response times for faster iteration during development phases.

FAQs

How to verify portable ice cube maker supplier reliability?

Validate certifications through issuing bodies and request third-party inspection reports (e.g., SGS, BV) covering electrical safety, material composition, and refrigerant compliance. Analyze transaction history for consistent order fulfillment and customer retention metrics. Conduct video audits of production lines to confirm in-house capabilities.

What is the typical sampling timeline?

Standard samples are produced within 7–12 days. Customized units with unique molds or circuitry require 15–20 days. Air shipping adds 5–8 days for international delivery. Some suppliers offer free samples for qualifying bulk orders (e.g., 500+ units).

Can suppliers ship globally?

Yes, established exporters manage worldwide logistics via FOB, CIF, or DDP terms. Confirm compatibility with destination voltage standards and customs requirements for refrigerant-containing appliances. Sea freight is optimal for full-container loads; air freight suits urgent or small-batch shipments.

Do manufacturers support OEM/ODM services?

All listed suppliers offer OEM branding (logo, packaging) and select provide ODM support for structural, functional, or power source modifications. Minimum order thresholds apply, typically starting at 500 units for full design changes.

What materials are commonly used in construction?

Housing typically uses ABS or stainless steel; internal components include aluminum evaporators and copper refrigerant lines. Compressors are hermetic rotary or reciprocating types. Ice trays are food-grade PP or silicone. Material selection impacts durability, cooling speed, and regulatory compliance.