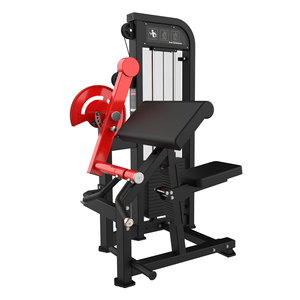

Bicep Curl Machine Producer

1/24

1/24

1/16

1/16

CN

CN

1/17

1/17

1/16

1/16

1/12

1/12

1/44

1/44

1/13

1/13

About bicep curl machine producer

Where to Find Bicep Curl Machine Producers?

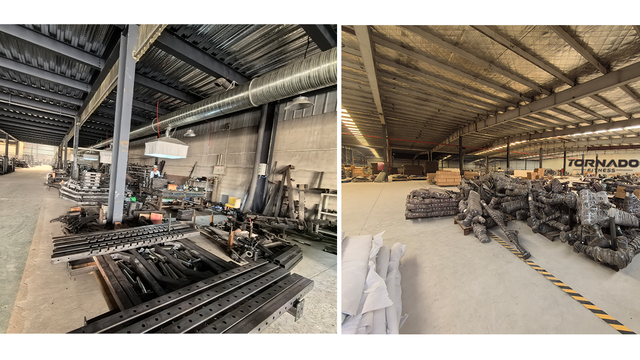

China remains the central hub for commercial fitness equipment manufacturing, with key production clusters in Shandong and Hebei provinces driving global supply. Shandong, particularly Qingdao, hosts specialized manufacturers integrating R&D, fabrication, and export logistics within consolidated facilities. These suppliers benefit from proximity to steel processing centers and port infrastructure, enabling cost efficiencies of 15–25% on raw materials and streamlined outbound shipping. Hebei’s Dingzhou region has emerged as a secondary cluster, focusing on high-volume production of plate-loaded and pin-loaded gym machines, including bicep curl models.

These industrial zones support vertically integrated operations—from CNC cutting and robotic welding to powder coating and final assembly—allowing producers to maintain tight control over quality and lead times. Suppliers in these regions typically operate production lines capable of delivering standard bicep curl machines within 20–35 days after order confirmation. The ecosystem includes ready access to component suppliers for pulleys, bearings, padding systems, and weight stacks, reducing dependency on external sourcing and enhancing customization agility.

How to Choose Bicep Curl Machine Producers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Production & Engineering Capability

Prioritize manufacturers with documented in-house production lines and engineering teams. Evidence of dedicated R&D units suggests capacity for design refinement and custom modifications. Confirm capabilities in metal fabrication—including laser cutting, bending, and MIG/TIG welding—as well as surface treatment processes like electrostatic painting or powder coating for durability.

Quality Assurance Protocols

While formal certifications (ISO 9001, CE) are not universally listed, assess quality through indirect indicators: consistent product specifications, material traceability, and structural testing claims. Look for suppliers referencing load testing, fatigue resistance, or ergonomic validation in product descriptions. For markets requiring regulatory compliance, verify that designs accommodate CE or ASTM F2216 standards for fitness equipment safety.

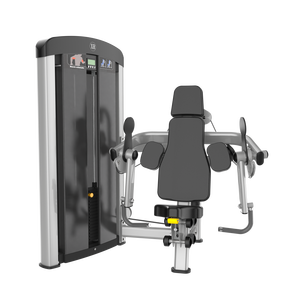

Customization & Flexibility

Evaluate scope for customization in:

- Frame geometry and user positioning (seated vs. standing configurations)

- Material selection (carbon steel gauge, PU padding thickness, anti-slip coatings)

- Branding options (laser-etched logos, color-matched finishes, custom decals)

- Packaging formats (flat-pack vs. fully assembled, export-grade wood crates)

Cross-reference customization claims with actual buyer feedback or reorder rates where available.

Transaction Reliability Metrics

Use performance data to assess dependability:

- On-time delivery rate ≥96% indicates reliable production scheduling

- Average response time ≤5 hours supports efficient communication

- Reorder rate >20% reflects customer retention and satisfaction

- Verified customization experience reduces risk in tailored orders

What Are the Leading Bicep Curl Machine Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| QLI FITNESS EQUIPMENT COMPANY LIMITED | Shandong, CN | Plate Loaded Machines, Pin Load Selection, Multi Function Stations | US $30,000+ | 50% | ≤5h | - | 1 piece | $713–1,657 |

| Qingdao Long Glory International Trading Co., Ltd. | Shandong, CN | Pin-Loaded, Adjustable Biceps/Triceps Equipment | US $430,000+ | 100% | ≤2h | <15% | 1–2 sets | $650–919 |

| Tornado Fitness Equipments.,LTD | Shandong, CN | Plate Loaded, Metal Frame Bicep Machines | US $7,000+ | 100% | ≤5h | - | 1–2 pieces | $597–921 |

| Dingzhou Zhongtengsubo Sporting Goods Co., Ltd. | Hebei, CN | Commercial Plate-Loaded Gym Equipment | US $4,700,000+ | 96% | ≤3h | 20% | 5 sets | $268–947 |

| Qingdao Sirer Technology Co., Ltd. | Shandong, CN | Adjustable Arm Curl, Factory-Direct Metal Frames | US $30,000+ | 100% | ≤1h | 27% | 1–2 pieces | $185–775 |

Performance Analysis

Qingdao-based manufacturers dominate responsiveness and delivery consistency, with three suppliers achieving 100% on-time fulfillment. Qingdao Sirer Technology stands out with a ≤1-hour response time and 27% reorder rate, indicating strong post-sale reliability. In contrast, QLI FITNESS shows a notably lower on-time delivery rate (50%), suggesting potential bottlenecks despite offering premium-priced models.

Dingzhou Zhongtengsubo demonstrates high scalability with the largest reported online revenue ($4.7M+) and offers the lowest price point at $268/set, though minimum orders start at 5 sets. This positions them as optimal for bulk procurement. Tornado Fitness and Qingdao Long Glory provide mid-range pricing with full customization support, suitable for buyers seeking balanced cost-performance ratios.

Price dispersion—from $185 to $1,657—reflects differences in build quality, materials, and order volume. Lower-cost models often use thinner steel gauges and simplified adjustment mechanisms, while higher-end units feature multi-position ergonomics and reinforced pivot points.

FAQs

How to verify bicep curl machine producer credibility?

Request factory audit reports or video walkthroughs confirming production line ownership. Validate claimed capabilities against product consistency, material specifications, and packaging details. Check historical transaction data for delivery performance and dispute resolution history.

What is the typical lead time for bicep curl machine orders?

Standard production lead times range from 20 to 35 days after deposit receipt. Customized models may require an additional 7–14 days depending on design complexity. Air freight samples can arrive in 7–10 days; sea freight takes 25–40 days based on destination.

Do suppliers offer OEM/ODM services?

Yes, multiple producers list customization options for color, logo, frame dimensions, and packaging. Verified manufacturers provide mockups and technical drawings upon request. Minimum order quantities for branded units vary—typically 5 sets for full OEM runs.

What are common MOQ and pricing structures?

MOQ ranges from 1 piece (for premium models) to 5 sets (for budget mass orders). Unit prices decrease significantly with volume: single-unit prices exceed $700, while bulk orders achieve sub-$300 rates. Negotiation leverage increases with order size and long-term partnership intent.

How should sampling be approached?

Order samples to evaluate weld quality, joint stability, padding density, and user ergonomics. Most suppliers charge sample fees, which may be credited toward future bulk orders. Confirm whether shipping is DDP or FOB to assess landed cost accurately.