Big Ball Ice Cube Maker

Top sponsor listing

Top sponsor listing

1/27

1/27

1/23

1/23

1/18

1/18

1/16

1/16

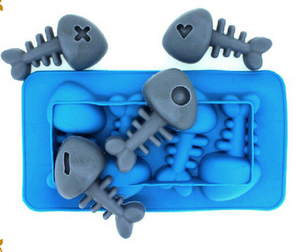

About big ball ice cube maker

Where to Find Big Ball Ice Cube Maker Suppliers?

China remains the central hub for manufacturing big ball ice cube makers, with key production clusters in Guangdong and Jiangsu provinces. These regions host vertically integrated supply chains specializing in silicone molding, food-grade plastic fabrication, and small kitchen appliance assembly. Dongguan and Yuyao serve as core manufacturing zones, offering access to advanced injection molding facilities and polymer material testing labs that support compliance with international food safety standards.

The industrial ecosystem enables rapid prototyping and scalable production, with many suppliers operating end-to-end processes—from mold design to packaging. This integration reduces component sourcing delays and supports MOQs as low as 50 pieces for niche designs. Buyers benefit from localized supplier networks where raw material providers, quality inspectors, and logistics partners operate within close proximity, ensuring lead times typically ranging from 15–25 days for standard orders. Cost efficiency is further enhanced by 20–30% lower labor and tooling expenses compared to Western alternatives.

How to Choose Big Ball Ice Cube Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional criteria:

Material & Safety Compliance

Confirm use of BPA-free, food-grade silicone or PP/PC plastics compliant with FDA, LFGB, or EU 10/2011 regulations. Request test reports for heavy metals and migration resistance. For export markets, CE or RoHS certification may be required depending on destination regulations.

Production and Customization Capacity

Assess capabilities through the following indicators:

- Minimum facility size of 2,000m² for consistent batch output

- In-house mold design and 3D rendering services for custom shapes, logos, or labeling

- Capacity for multi-cavity molds supporting spherical (60–70mm diameter), bullet, or rectangular large-format cubes

Cross-reference customization claims with actual product listings showing unique lid designs, color options, or packaging configurations.

Order Fulfillment Metrics

Prioritize suppliers with documented on-time delivery rates exceeding 95%. Analyze response time (ideally ≤6 hours) and reorder rate as proxies for customer satisfaction. Verify scalability through historical online revenue data and minimum order flexibility—suppliers capable of handling both 100-piece samples and 10,000+ unit bulk orders demonstrate stronger operational control.

What Are the Best Big Ball Ice Cube Maker Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Sample MOQ | Key Product Features |

|---|---|---|---|---|---|---|---|---|

| Dongguan Lucky Goldjyx Company Limited | Cake Tools, Baking & Pastry Tools, Ice Cream Tools | 90% | ≤6h | <15% | US $410,000+ | Color, shape, lid, packaging, label, material, size, logo, mold design, 3D drawings | 500 sets | Food-grade materials, full branding capability |

| Jiangmen TW Industry Co., Ltd. | Cake Tools, Mats & Pads, Pet Bowls, Baking Tools | 100% | ≤4h | 42% | US $40,000+ | Limited customization per listing | 500–1,000 pcs | BPA-free silicone, multi-cavity molds |

| Yuyao Haohong Electrical Appliance Co., Ltd. | Ice Makers, Car Fridges, Compact Refrigerators | 100% | ≤2h | <15% | US $170,000+ | Not specified | 100–270 pcs | Premium pricing, crystal-clear ice focus |

| Dongguan Kaijing Electronics Co., Ltd. | Ice Cream Tools, Cake Tools, Household Sundries | 100% | ≤7h | - | - | Basic shape variation | 100 pcs | Low-cost silicone molds, eco-friendly materials |

| Foshan Greenkitchen Rubber Plastic Products Co., Ltd. | Kids Dining Utensils, Ice Cream Tools, Cake Tools | 83% | ≤17h | 20% | US $4,000+ | Lid inclusion, color options | 50–500 pcs | Low MOQ, fast sampling |

Performance Analysis

Jiangmen TW Industry and Yuyao Haohong stand out for perfect on-time delivery records and strong responsiveness, indicating reliable production scheduling. Jiangmen TW’s 42% reorder rate suggests high buyer retention, likely driven by consistent quality in BPA-free silicone molds. Dongguan Lucky Goldjyx offers the most extensive customization suite—including full mold and graphic design—making it ideal for branded private-label development despite a higher reorder threshold. Foshan Greenkitchen provides the lowest entry MOQ (50 pieces), beneficial for startups or market testing. However, its 83% on-time rate and slower response time present risk factors for time-sensitive campaigns. Dongguan Kaijing delivers competitive pricing and broad product variety but lacks transparency in financial performance and repeat business metrics.

FAQs

How to verify big ball ice cube maker material safety?

Request compliance documentation such as FDA or EU 10/2011 test reports. For silicone products, confirm Shore A hardness ratings between 40–60 for durability and flexibility. Conduct third-party lab tests if high-volume distribution in regulated markets (EU, North America) is planned.

What is the typical lead time for bulk orders?

Standard production cycles range from 15 to 25 days after sample approval. Orders requiring custom molds may extend lead times by 10–14 days for tooling fabrication. Air freight adds 5–7 days; sea shipping takes 25–35 days depending on destination port.

Can suppliers provide free samples?

Most suppliers offer paid samples with fees redeemable against future orders. Sample costs typically range from $30–$150 depending on complexity. Free samples are occasionally provided for high-potential buyers placing imminent bulk contracts.

Do manufacturers support private labeling and packaging?

Yes, especially among suppliers like Dongguan Lucky Goldjyx that explicitly list logo, label, and packaging customization. Provide vector artwork and Pantone codes for accurate reproduction. Minimum branding quantities vary—typically 500 units for printed labels or molded logos.

How to initiate mold development for a custom ice sphere design?

Submit detailed specifications including desired diameter (commonly 60–70mm), wall thickness, cavity count, and ejection mechanism. Reputable suppliers will generate 3D CAD models within 3–5 business days and complete mold production in 7–10 days. Mold costs range from $300–$800 depending on complexity and steel grade (e.g., NAK80 vs. S136).