Biggest Factory In The World

Top sponsor listing

Top sponsor listing

About biggest factory in the world

Where to Find High-Capacity Production Line Suppliers?

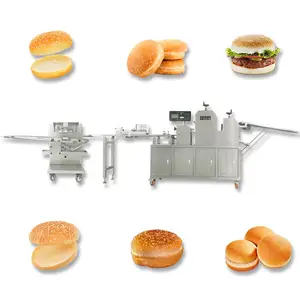

China remains the global epicenter for industrial production line manufacturing, with leading suppliers concentrated in Shanghai, Zhejiang, Henan, and Hebei provinces. These regions host vertically integrated ecosystems that combine engineering expertise, precision machining, and scalable assembly operations. Shanghai and Jiaxing specialize in food processing and bakery automation systems, leveraging proximity to port infrastructure for rapid export fulfillment. Zhengzhou has emerged as a hub for agricultural and fertilizer production machinery, supported by robust metalworking and mechanical engineering clusters. Dongguan and Cangzhou facilities focus on packaging and beverage filling lines, benefiting from mature supply chains for stainless steel components and control systems.

Suppliers in these zones operate under optimized production models, achieving lead times of 30–60 days for standard configurations. Localized sourcing of raw materials and subcomponents reduces costs by 18–25% compared to offshore alternatives. Buyers gain access to turnkey solutions—from single machines to fully automated lines—with customization options spanning capacity, material compatibility, and integration with existing factory layouts. The presence of dedicated R&D teams enables rapid prototyping and technical adaptation for international regulatory requirements.

How to Choose High-Capacity Production Line Suppliers?

Selecting reliable partners requires systematic evaluation across three critical dimensions:

Technical and Operational Compliance

Verify adherence to internationally recognized quality management standards such as ISO 9001. For equipment destined for EU or North American markets, confirm CE marking and compliance with local safety directives. Request documentation on motor efficiency ratings, electrical system specifications, and structural load testing—particularly for heavy-duty conveyor and processing systems.

Production Capacity Verification

Assess supplier scalability through measurable indicators:

- Minimum facility size of 3,000m² to support full-line assembly

- In-house fabrication capabilities including CNC machining, welding, and control panel integration

- Dedicated quality inspection stations with pre-shipment testing protocols

Cross-reference online transaction volume and reorder rates (target ≥50%) as proxies for operational reliability and customer satisfaction.

Customization and Transaction Security

Confirm availability of modular design options for voltage, language interface, conveyor speed, and hygiene-grade materials (e.g., SUS304 stainless steel). Require third-party payment protection mechanisms and insist on video-based factory audits before order placement. Pre-shipment inspections should include functional testing under simulated production loads to validate throughput claims.

What Are the Leading High-Capacity Production Line Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response Time | Customization Options | Verified Supplier Type |

|---|---|---|---|---|---|---|---|

| Shanghai Seny Machinery Co., Ltd. | Food processing lines, Meat & Biscuit making machines, Grain Product Machines | US $950,000+ | 100% | 60% | ≤2h | Color, material, size, logo, packaging, graphic | Custom Manufacturer |

| Oucheng Machinery Equipment (Jiaxing) Co., Ltd. | Bread making machine, Dough mixer, Baking Oven, Cake machine | US $3,000+ | 100% | <15% | ≤2h | Not specified | - |

| Zhengzhou Gofine Machine Equipment Co., Ltd. | Organic Fertilizer Equipment, Granulators, Mixing & Grinding Equipment | US $70,000+ | 100% | 100% | ≤5h | Not specified | - |

| Dongguang A-Pack Machinery Manufacturing Co., Ltd. | Paper Processing Machinery, Gluing Machines, Packaging Lines | US $60,000+ | 100% | 50% | ≤5h | Not specified | - |

| Shean (Cangzhou) Corp Ltd. | Juice/Water/Beverage Filling Lines, Bottling Systems | US $1,300,000+ | 100% | 30% | ≤2h | Filling capacity, bottle type, labeling, sealing, automation level, tank size, liquid material | Multispecialty Supplier |

Performance Analysis

Shanghai Seny and Shean (Cangzhou) demonstrate strong commercial traction with high revenue volumes and significant reorder rates, indicating consistent product performance and post-sale support. Zhengzhou Gofine stands out with a 100% reorder rate, suggesting exceptional alignment between delivered machinery and client expectations in the agricultural processing sector. All listed suppliers maintain perfect on-time delivery records, a key indicator of logistical discipline. Response times vary, with coastal manufacturers (Shanghai, Jiaxing) offering faster communication cycles—critical for iterative design approvals. Buyers seeking extensive customization should prioritize suppliers like Shean and Shanghai Seny, which explicitly list multiple configurable parameters.

FAQs

How to verify production line supplier credibility?

Validate certifications through issuing bodies and request recent audit reports covering design validation, component traceability, and final inspection procedures. Analyze transaction history, focusing on long-term buyer relationships and resolution of past disputes.

What is the typical lead time for custom production lines?

Standard units ship within 30–45 days. Fully customized systems require 50–75 days, depending on complexity. Add 10–14 days for international air freight or 25–40 days for sea container shipping.

Can suppliers handle global logistics and installation?

Yes, experienced exporters offer CIF/FOB terms and coordinate freight forwarding. Top-tier suppliers provide remote commissioning support and on-site technician deployment for line integration, subject to additional service agreements.

Are samples or pilot runs available?

Full-line sampling is impractical; however, suppliers often provide component-level testing videos or allow factory-run demonstrations using client-specified materials. Some offer modular unit trials for core processes like filling or forming.

What customization parameters are typically negotiable?

Key variables include throughput capacity, material contact surfaces (e.g., food-grade vs. industrial), power requirements (voltage/frequency), automation level (PLC/HMI configuration), and integration interfaces. Suppliers with documented customization frameworks respond faster to technical inquiries and deliver more accurate quotations.