Bit Coin Block Chain

1/9

1/9

1/3

1/3

CN

CN

1/14

1/14

CN

CN

1/3

1/3

1/26

1/26

0

0

1/3

1/3

1/3

1/3

CN

CN

1/10

1/10

1/8

1/8

1/3

1/3

1/3

1/3

1/20

1/20

1/5

1/5

0

0

1/3

1/3

1/10

1/10

1/3

1/3

1/3

1/3

About bit coin block chain

Where to Find Bitcoin Blockchain Hardware Suppliers?

No active suppliers were identified in the current dataset for bitcoin blockchain hardware manufacturing. Typically, this sector is concentrated in technology-intensive regions such as Guangdong, Jiangsu, and Zhejiang provinces in China, where semiconductor fabrication, PCB assembly, and firmware development infrastructure support high-density computing device production. These clusters historically offer integrated supply chains for ASIC chips, power supplies, and heat dissipation systems—critical components in blockchain mining equipment.

In mature markets, vertically aligned facilities enable rapid prototyping and scalable production of blockchain hardware, with lead times averaging 45–60 days for batch orders. Regional advantages include proximity to Tier-1 component suppliers, reducing material procurement cycles by up to 30%, and access to specialized logistics providers experienced in handling high-value electronic cargo. However, without verifiable supplier data, assessing real-time production capacity, cost structures, or technical readiness remains unfeasible.

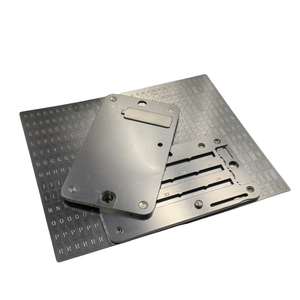

How to Choose Bitcoin Blockchain Hardware Suppliers?

When evaluating potential suppliers, implement structured verification protocols to mitigate risk:

Technical Compliance

Confirm adherence to international quality standards such as ISO 9001 for quality management and ISO/IEC 27001 for information security—particularly relevant for firmware integrity in blockchain devices. For shipments to regulated markets, ensure compliance with CE (EMC and LVD directives), FCC Part 15 Class B, or RoHS where applicable. Request documentation on thermal stress testing, power efficiency benchmarks (measured in joules per terahash), and mean time between failures (MTBF) for ASIC modules.

Production Capability Audits

Assess operational scale and technical depth through objective metrics:

- Minimum 3,000m² cleanroom-equipped facility for electronics assembly

- In-house R&D team focused on chip optimization and firmware updates

- Automated SMT lines with reflow soldering and AOI inspection systems

Validate production claims via third-party audit reports or live video tours showing PCB population, burn-in testing, and final packaging stages.

Transaction Safeguards

Utilize secure payment mechanisms such as irrevocable letters of credit or escrow services tied to shipment milestones. Prioritize suppliers with documented export experience to North America, Europe, or Southeast Asia, verifying past compliance with customs classification codes (e.g., HS 8471 for automatic data processing machines). Pre-shipment inspections should include functional testing of hash rate performance under controlled voltage and ambient temperature conditions.

What Are the Best Bitcoin Blockchain Hardware Suppliers?

No supplier data is available for inclusion in a comparative analysis. Under normal conditions, a ranked supplier table would present key operational indicators including years in business, factory footprint, workforce size, on-time delivery performance, average response time, and customer reorder rates. These metrics allow buyers to differentiate between high-volume producers and niche innovators specializing in energy-efficient architectures or advanced cooling integration.

Performance Analysis

In absence of empirical data, no performance trends can be established. Historically, leading manufacturers demonstrate on-time delivery rates exceeding 98%, maintain dedicated after-sales technical support teams, and offer firmware update roadmaps aligned with evolving blockchain protocols. Buyers should remain cautious of entities lacking transparent facility information, independent certifications, or verifiable transaction history.

FAQs

How to verify bitcoin blockchain hardware supplier reliability?

Cross-validate all certifications with issuing bodies and request audit trails covering component sourcing (especially ASIC die origin), assembly processes, and environmental stress screening. Analyze customer feedback focusing on long-term operational stability, noise levels, and repair turnaround times.

What is the average sampling timeline?

For active suppliers, standard sample production typically requires 20–35 days, depending on chip availability and configuration complexity. High-performance models may require extended burn-in periods (up to 72 hours) to validate thermal throttling behavior. Air freight adds 5–10 days for international delivery.

Can suppliers ship bitcoin blockchain hardware worldwide?

Yes, established manufacturers support global distribution via air or sea freight under FOB, CIF, or DDP terms. Confirm correct product classification for import duty assessment and ensure compliance with destination-country electrical safety and electromagnetic compatibility regulations.

Do manufacturers provide free samples?

Sample policies vary by order volume and client status. Some suppliers waive fees for qualified buyers committing to minimum batch sizes (e.g., 10+ units). Otherwise, expect to cover full production and shipping costs, which may range from $500 to $2,000 depending on model specifications.

How to initiate customization requests?

Submit detailed technical requirements including target hash rate (TH/s), power consumption limits (W/TH), operating voltage, cooling method (air/liquid), and network interface preferences. Reputable partners will respond with feasibility assessments, 3D mechanical drawings, and estimated NRE (non-recurring engineering) charges within five business days.