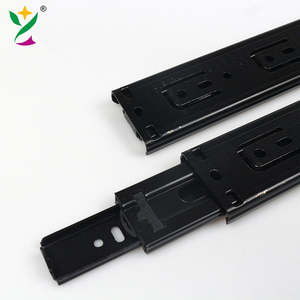

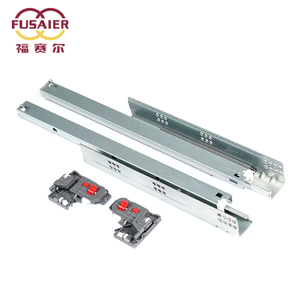

Bottom Mount Drawer Slides

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/25

1/25

1/3

1/3

1/3

1/3

1/3

1/3

1/28

1/28

1/2

1/2

1/32

1/32

About bottom mount drawer slides

Where to Find Bottom Mount Drawer Slides Suppliers?

China remains the global epicenter for bottom mount drawer slide production, with key manufacturing clusters concentrated in Guangdong, Fujian, and Zhejiang provinces. These regions host vertically integrated supply chains that combine cold-rolled steel processing, precision stamping, ball bearing assembly, and automated finishing lines within compact industrial zones. Guangdong alone accounts for over 40% of China’s furniture hardware exports, supported by mature logistics networks enabling efficient air and sea freight consolidation.

Suppliers in these hubs benefit from proximity to raw material sources and component manufacturers, reducing lead times by 15–25% compared to offshore alternatives. The ecosystem supports both high-volume OEM contracts and low-MOQ customized orders, with many factories operating multi-shift production schedules to maintain output flexibility. Average monthly capacities range from 500,000 to over 2 million units per facility, depending on automation levels and product complexity.

How to Choose Bottom Mount Drawer Slides Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to international standards such as ISO 9001 for quality management systems. For markets in Europe and North America, confirm CE marking or compliance with ANSI/BHMA A156.7 for durability and load performance. Request test reports on key metrics including cycle life (minimum 50,000 open/close cycles), load capacity (rated at 20–45 kg per pair), and corrosion resistance (salt spray testing ≥72 hours).

Production & Customization Capability

Assess core competencies through the following indicators:

- In-house tooling and mold-making capabilities for custom profiles

- Availability of laser cutting, CNC bending, and robotic welding for dimensional accuracy

- Surface treatment options: electroplating, powder coating, or black oxide finishes

- Support for customization: length (250–600mm standard), load rating, damping mechanism, packaging, and labeling

Cross-reference supplier claims with listed product variations and reorder rates to gauge market acceptance.

Transaction Reliability Metrics

Prioritize suppliers demonstrating consistent performance:

- On-time delivery rate ≥96%

- Average response time ≤4 hours

- Reorder rate >15% indicating customer retention

- Transparent pricing structures with clear MOQ thresholds

Utilize verifiable transaction data—such as online revenue bands and order history—to assess scalability and financial stability.

What Are the Best Bottom Mount Drawer Slides Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Notable Product Features |

|---|---|---|---|---|---|---|---|

| Guangdong Yuxing Industry Co., Ltd. | Furniture Hinges (132) Drawer Slides (124) | US $1,000,000+ | 100% | ≤3h | 25% | Color, material, size, logo, packaging, label, graphic | High-volume full-extension models; soft-close mechanisms |

| Jieyang City Kelo Hardware Manufacturer Co., Ltd. | Furniture Hinges (145) Drawer Slides (87) | US $540,000+ | 100% | ≤4h | <15% | Not specified | Cost-effective partial extension slides; push-to-open variants |

| Xiancheng (Shanghai) Information Technology Co., Ltd. | Drawer Slides (multiple) | US $20,000+ | 100% | ≤3h | <15% | Logo, packaging | Three-section full extension; heavy-duty damped models |

| Foshan Feifule Hardware Co., Ltd. | Drawer Slides (103) Furniture Hinges (61) | US $50,000+ | 100% | ≤3h | <15% | Not specified | Soft-close concealed slides; machine production line components |

| Guangzhou Rongtai Hardware Product Limited | Door & Window Handles (225) Furniture Locks (190) | US $430,000+ | 96% | ≤3h | <15% | Not specified | Premium slim steel designs; push-open undermount systems |

Performance Analysis

Guangdong Yuxing stands out with the highest online revenue and a 25% reorder rate, indicating strong buyer satisfaction and repeat business. Its extensive customization portfolio supports diverse branding and integration needs. Jieyang City Kelo and Foshan Feifule offer competitive pricing models with MOQs starting as low as 10 pairs, suitable for prototyping or niche applications. Xiancheng (Shanghai) targets specialized segments with high-performance damped and full-extension variants, though lower revenue suggests narrower market penetration. Guangzhou Rongtai maintains broad hardware diversification but allocates fewer listings to drawer slides, potentially limiting focus in this category.

FAQs

What is the typical MOQ for bottom mount drawer slides?

Minimum order quantities vary by supplier and model. Standard configurations start at 10–500 pairs, while bulk pricing applies at 1,000+ units. Some suppliers offer single-pair sampling for evaluation, particularly for new buyers.

How long do production and shipping take?

Standard lead times range from 15 to 30 days after order confirmation, depending on customization level. Add 5–7 days for air freight or 25–40 days for sea shipping to most international destinations. Expedited production (7–10 days) may be available for urgent orders at premium rates.

Can suppliers provide free samples?

Sample policies differ. Many suppliers offer paid samples with fees redeemable against future orders. Fully free samples are typically reserved for qualified buyers placing imminent volume contracts. Expect sample costs between $10–$150 based on complexity.

Are bottom mount slides compatible with all cabinet types?

Compatibility depends on mounting clearance, drawer box depth, and side panel thickness. Most standard slides require 12–15mm bottom rail space and 15–18mm side clearance. Confirm dimensional specifications and installation templates with the supplier prior to integration.

What materials are used in manufacturing?

Primary materials include cold-rolled carbon steel (SPCC/SECC) for structural strength, paired with hardened ball bearings for smooth operation. Stainless steel variants are available for moisture-prone environments. Surface coatings such as zinc plating or epoxy enhance wear and corrosion resistance.