Box Plot Maker

1/26

1/26

1/3

1/3

1/41

1/41

1/24

1/24

1/2

1/2

1/23

1/23

1/18

1/18

1/19

1/19

0

0

1/15

1/15

1/3

1/3

1/23

1/23

1/5

1/5

1/3

1/3

1/3

1/3

1/37

1/37

1/3

1/3

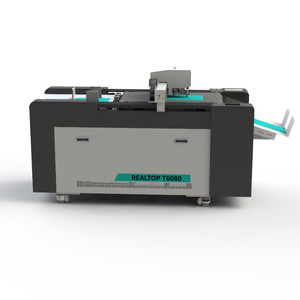

About box plot maker

Where to Find Box Plot Maker Suppliers?

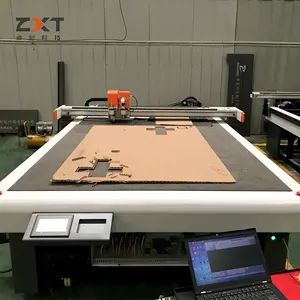

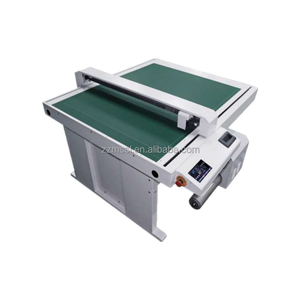

China remains the central hub for box plot maker manufacturing, with key production clusters in Guangdong, Anhui, and Zhejiang provinces. These regions host vertically integrated facilities specializing in digital flatbed cutting and die-cutting machinery used in packaging, signage, and label production. Shenzhen (Guangdong) is a technological epicenter for compact, high-precision double-head plotters targeting small-to-midsize enterprises, while Hefei (Anhui) and Wenzhou (Zhejiang) focus on industrial-scale automated systems for rigid box and corrugated packaging fabrication.

The clustering enables streamlined access to component suppliers for servo motors, CCD cameras, ARM CPUs, and precision blades, reducing lead times by 20–30% compared to decentralized production models. Suppliers in these zones typically operate under agile manufacturing frameworks, supporting both low-volume custom orders and mass production runs. Average delivery timelines range from 15–30 days for standard units, with export-ready logistics networks covering North America, Europe, and Southeast Asia.

How to Choose Box Plot Maker Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional criteria:

Technical Specifications & Compliance

Confirm compatibility with required materials—corrugated board, coated paper, vinyl, or laminated cardboard—and verify supported software ecosystems (e.g., CorelDRAW, SignMaster). While explicit ISO or CE certifications are not always listed, prioritize suppliers offering detailed machine specifications, built-in registration mark detection, and precision control systems (±0.1mm accuracy). For international compliance, ensure electromagnetic and safety standards align with destination market regulations.

Production and Customization Capacity

Assess supplier capability through infrastructure indicators:

- Minimum factory area exceeding 2,000m² for stable output

- In-house R&D teams supporting firmware/software integration

- Customization options for dual-head configurations, laser alignment, adjustable pressure control, and network connectivity (Ethernet/USB)

Cross-reference product listings with response time (target ≤5 hours) and on-time delivery rates (ideally ≥94%) as proxies for operational reliability.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services where available. Request sample testing to evaluate cutting precision, blade durability, and contour registration accuracy. Verify material handling capacity—maximum cutting width (up to 900mm), thickness tolerance (up to 10mm for corrugated), and support for roll-fed or sheet-fed formats—before scaling procurement.

What Are the Best Box Plot Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Huansheng Intelligence (Shenzhen) Co., Ltd. | Shenzhen, CN | Custom Manufacturer | $270,000+ | 91% | ≤5h | 26% | 4 | $1,000–2,100 |

| Hefei Kaxing Digital Control Equipment Co., Ltd. | Hefei, CN | Multispecialty Supplier | $320,000+ | 100% | ≤2h | <15% | 4 | $270–2,199 |

| Ningbo Jingwei Systemtechnik Ltd | Ningbo, CN | - | - | 100% | ≤1h | - | 4 | $3,000–55,000 |

| Shenzhen Momo Digital Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | $320,000+ | 94% | ≤4h | <15% | 5 | $790–5,098 |

| Wenzhou Rongda Packaging Equipment Co., Ltd. | Wenzhou, CN | Multispecialty Supplier | $10,000+ | 100% | ≤3h | <15% | 5 | $15,000–180,000 |

Performance Analysis

Mid-range manufacturers like Huansheng Intelligence and Shenzhen Momo offer competitive pricing and strong reorder metrics (26%), indicating customer satisfaction in niche markets for A3/A4-sized double-head plotters. Hefei Kaxing stands out with 100% on-time delivery and sub-2-hour response times, ideal for urgent procurement cycles. At the high end, Wenzhou Rongda specializes in fully automatic rigid box making lines priced between $15,000–180,000, catering to large-scale packaging operations requiring minimal manual intervention. Ningbo Jingwei presents a wide cost spectrum, including high-capacity CNC-based systems for corrugated processing, though limited reorder data suggests lower buyer recurrence. Prioritize suppliers with documented customization capabilities and multi-material processing experience when integrating into diverse production environments.

FAQs

How to verify box plot maker supplier reliability?

Evaluate responsiveness (target ≤5h), on-time delivery rate (preferably >94%), and evidence of after-sales support. Request machine operation videos, software interface demos, and third-party inspection reports if available. Analyze listed features—such as CCD camera registration, servo motor drives, and QR code scanning—for consistency with claimed performance levels.

What is the average lead time for box plot makers?

Standard units ship within 15–25 days after order confirmation. Customized configurations involving dual heads, specialized blades, or integrated software may require 30–45 days. Air freight adds 5–10 days for international delivery; sea freight takes 25–40 days depending on destination port.

Can suppliers accommodate customization requests?

Yes, most verified suppliers support modifications including language settings, logo branding, cutting area adjustments, material-specific pressure calibration, and compatibility with design plugins (e.g., CDR). Submit detailed technical requirements early in negotiations to assess feasibility and timeline impact.

Do box plot makers support various materials?

Top-tier models handle corrugated cardboard, coated paper, vinyl stickers, gift boxes, and laminated sheets. Ensure the machine specifies compatibility with your primary substrate and includes appropriate tooling—vibrating knives for thick board, laser guides for precision contours, and creasing tools for foldable packaging.

Are samples available before bulk ordering?

Sample policies vary. Some suppliers provide test cuts or demo units upon request, often refundable against future orders. For high-value machinery, virtual demonstrations and factory live streams serve as effective alternatives to physical sampling.