Build Scaffolding Factories

Top sponsor listing

Top sponsor listing

0

0

1/14

1/14

0

0

0

0

CN

CN

1/7

1/7

1/16

1/16

1/15

1/15

1/3

1/3

CN

CN

1/22

1/22

1/20

1/20

1/3

1/3

1/10

1/10

1/3

1/3

1/3

1/3

1/13

1/13

1/8

1/8

About build scaffolding factories

Where to Find Build Scaffolding Factory Suppliers?

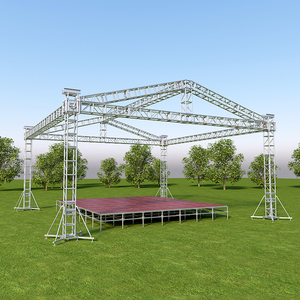

China remains the global hub for scaffolding manufacturing, with key production clusters concentrated in Tianjin, Hebei, Sichuan, and Jiangxi provinces. These regions host vertically integrated metal fabrication facilities specializing in cold-formed steel processing, galvanization, and modular assembly—critical for high-volume production of frame, ringlock, and mobile scaffolding systems. The proximity of raw material suppliers and logistics networks enables cost efficiencies, with localized supply chains reducing component procurement lead times by 20–30% compared to non-specialized regions.

Suppliers in these industrial zones operate dedicated production lines for standardized and customizable scaffolding solutions, serving both domestic construction markets and export demand across Europe, Southeast Asia, and North America. Facilities typically maintain in-house cutting, welding, powder coating, and packaging capabilities, allowing end-to-end control over quality and delivery timelines. Buyers benefit from scalable output, with average monthly capacities ranging from 5,000 to 20,000 units depending on product complexity and order specifications.

How to Choose Build Scaffolding Factory Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Production and Customization Capability

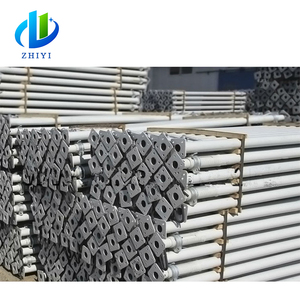

Confirm that suppliers possess in-house manufacturing infrastructure—including CNC tube bending, automatic welding, and surface treatment processes—to support consistent quality. Key indicators include customization options for pipe diameter (typically 48.3mm or 60.3mm), wall thickness (2.75–4.0mm), height, platform size, and load capacity. Leading factories offer OEM/ODM services with design input on structural drawings, labeling, color coding, and graphic branding.

Quality Assurance and Compliance

Prioritize suppliers adhering to international safety and performance standards such as EN 1065, BS 1139, or OSHA regulations. While explicit certification data is not provided, evaluate compliance readiness through documented testing procedures for weld integrity, corrosion resistance (via hot-dip galvanizing), and load-bearing stability. On-time delivery rates above 96% correlate with robust internal quality management systems.

Operational Performance Metrics

Use verifiable performance indicators to assess reliability:

- On-time delivery rate ≥97% indicates strong production planning and logistics coordination

- Average response time ≤2 hours reflects proactive customer service capacity

- Reorder rates >30% suggest high client satisfaction and product consistency

- Minimum Order Quantity (MOQ) varies: some suppliers accept 1-piece trials; others require 50–100 sets for customized configurations

Procurement Safeguards

Leverage structured sampling protocols before full-scale orders. Request physical or digital samples with detailed specifications (material grade, coating thickness, dimensional accuracy). Verify packaging methods and export readiness, especially for海运 shipments requiring moisture-resistant wrapping and palletized stacking. Consider phased payment terms tied to production milestones and third-party inspection at origin.

What Are the Best Build Scaffolding Factory Suppliers?

| Company Name | Verified Type | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Tianjin Zhiyi Metal Products Co., Ltd. | Custom Manufacturer | Scaffoldings, Formwork, Ladder & Scaffolding Parts, Timber Plywoods | Pipe diameter, thickness, color, material, size, painting layers, logo, plank height | 96% | ≤2h | US $2,900,000+ | 33% |

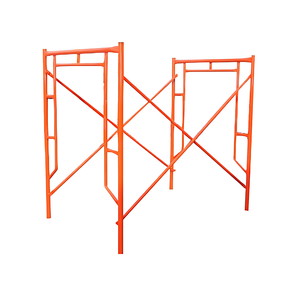

| Sichuan Xingbaili International Trade Co., Ltd. | - | Scaffolding Systems (Frame, H-Type, Bowl Buckle, Ringlock) | Color, material, size, logo, packaging, graphic | 100% | ≤1h | US $60,000+ | <15% |

| Xianxian Woheng Metal Products Co., Ltd. | - | Scaffoldings, Work Platforms, Hoists, Caster Wheels | Limited customization per listing | 100% | ≤1h | US $50,000+ | 16% |

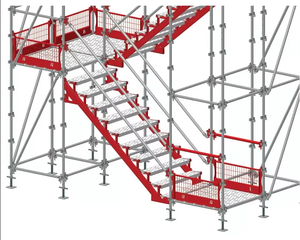

| Jiangxi Mide Industrial Co., Ltd. | Multispecialty Supplier | Electric Folding Scaffolds, Mobile Lifts (2–10m) | Platform size, height, capacity, color, logo, overall dimensions | 97% | ≤3h | US $380,000+ | <15% |

| Ya'an Rongtai Heavy Industry Co., Ltd. | - | Frame Scaffolding, A-Frame Walks, Aluminum Planks | Standard industrial specs only | 100% | ≤1h | US $70,000+ | <15% |

Performance Analysis

Tianjin Zhiyi stands out with the highest reported online revenue (US $2.9M+) and a 33% reorder rate, indicating strong market trust and repeat business—key markers of product reliability and service consistency. Despite a slightly lower on-time delivery rate (96%), its broad customization scope and diversified product range position it as a strategic partner for large-scale procurement. In contrast, Sichuan Xingbaili, Xianxian Woheng, and Ya’an Rongtai achieve perfect 100% on-time delivery records with sub-1 hour response times, making them ideal for urgent or time-sensitive orders despite lower reorder volumes.

Jiangxi Mide specializes in advanced electric and hydraulic folding scaffolds, targeting niche applications in commercial maintenance and high-rise building work. Its higher price point reflects added engineering complexity and automation features. Buyers seeking smart lifting solutions should prioritize this supplier for technical integration and CE-compliant design adaptation.

FAQs

How to verify build scaffolding factory reliability?

Evaluate on-time delivery history, response speed, and reorder rates as proxies for operational stability. Request evidence of production floor audits, material test reports (e.g., Q235/Q345 steel certification), and galvanization thickness (≥80µm recommended). Conduct video inspections to confirm in-house manufacturing claims versus trading operations.

What is the typical lead time for scaffolding orders?

Standard orders take 25–35 days from confirmation to shipment. Customized or large-volume batches may extend to 45 days, particularly for electro-hydraulic models requiring additional assembly and testing phases.

Can suppliers accommodate small trial orders?

Yes, multiple suppliers list minimum orders of 1 piece for standard scaffolding frames, enabling low-risk sampling. However, MOQs increase to 50–100 sets for customized configurations involving specific coatings, logos, or structural modifications.

Do manufacturers support global shipping?

All listed suppliers have export experience, with packaging adapted for containerized transport. Confirm FOB pricing, incoterms, and destination-specific regulatory requirements (e.g., CE marking for EU imports). Sea freight is standard; air shipping is viable for samples under 500 kg.

How to initiate customization requests?

Submit detailed technical parameters including required load capacity (kN/m²), working height, platform dimensions, material grade, surface finish (galvanized/painted), and branding elements. Reputable suppliers respond within 24 hours with feasibility assessments and CAD-based renderings for approval prior to prototyping.