Bulk Produce Bins

About bulk produce bins

Where to Find Bulk Produce Bins Suppliers?

China remains a central hub for bulk produce bin manufacturing, with key production clusters in Jiangxi and Qingdao regions driving export volume. These areas host vertically integrated facilities specializing in injection molding and HDPE/PP processing, enabling high-volume output of durable, food-grade storage solutions. Jiangxi-based suppliers focus on retail and supermarket display bins, emphasizing clarity, ergonomics, and modular stacking. In contrast, Qingdao manufacturers prioritize industrial-grade durability, producing heavy-duty folding totes, vented vegetable crates, and collapsible bulk containers designed for agricultural logistics and warehouse use.

The regional specialization supports differentiated sourcing strategies: Jiangxi factories offer competitive pricing for small to mid-volume buyers seeking customizable display-ready bins, while Qingdao’s proximity to major ports and steel supply chains reduces material costs and enhances freight efficiency. This geographic concentration enables faster turnaround times—typically 15–25 days for standard orders—and access to mature supplier ecosystems where mold fabrication, quality testing, and packaging operate within tightly coordinated networks.

How to Choose Bulk Produce Bin Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Material & Compliance Standards

Confirm that bins are manufactured from food-safe HDPE or PP resins compliant with FDA and EU food contact regulations. For international shipments, verify documentation for RoHS and LFGB testing. Bins intended for direct produce storage should feature sealed lids, antimicrobial surfaces, and UV stabilization where applicable.

Production Capacity and Flexibility

Assess operational scale through measurable indicators:

- Minimum factory area exceeding 2,000m² for consistent batch output

- In-house mold design and injection molding capabilities

- Customization capacity for size, color, labeling, and structural features (e.g., drop doors, stackability, base dimensions)

Cross-reference online revenue metrics and order fulfillment rates—suppliers with verified annual revenues above US $300,000 typically maintain stable production lines and inventory management systems.

Transaction Reliability Indicators

Prioritize suppliers demonstrating 100% on-time delivery performance and response times under 2 hours. Low reorder rates (<15%) suggest limited customer retention but may indicate niche specialization or new market entry rather than poor service. Utilize platform-verified transaction histories to assess dispute resolution effectiveness and sample accuracy.

What Are the Best Bulk Produce Bin Suppliers?

| Company Name | Location | Main Products | Customization Options | Min. Order Quantity | Avg. Price Range | On-Time Delivery | Avg. Response | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Jiangxi Yirong Commodity Co., Ltd. | Jiangxi, CN | Sealed food jars, scoop bins, clear display containers | Color, material, size, logo, shape, capacity | 2–10 pieces | $4–30 | 100% | ≤1h | US $290,000+ |

| Qingdao Cnplast Co., Ltd. | Qingdao, CN | Stackable harvest totes, pallets, collapsible containers | Size only | 2–50 pieces | $10–110 | 97% | ≤2h | US $680,000+ |

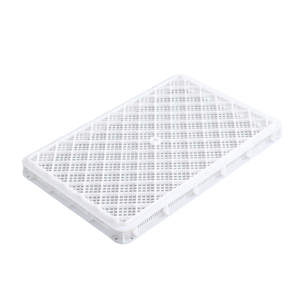

| Qingdao Zhiyuancheng Import And Export Co., Ltd. | Qingdao, CN | Folding harvest totes, fruit drying pallets, grid crates | Limited (price-driven) | 1–50 pieces | $1–7 | 100% | ≤2h | US $3,000+ |

| Qingdao Midwell Industry And Trade Co., Ltd. | Qingdao, CN | Heavy-duty warehouse bins, vented vegetable crates, mega containers | Not specified | 10–100 pieces | $120–200 | 100% | ≤2h | US $20,000+ |

| Jiangxi Eco Technology Group Co., Ltd. | Jiangxi, CN | Food-grade grocery bins, nut/cereal containers, legume displays | Color, size, cap type, scoop, label, shelf, logo | 2 pieces | $5–30 | 100% | ≤2h | US $370,000+ |

Performance Analysis

Jiangxi-based suppliers excel in customization depth and responsiveness, making them ideal for buyers requiring branded, retail-ready bins with tight design specifications. Jiangxi Yirong and Jiangxi Eco Technology offer broad aesthetic and functional adaptability at low MOQs, supporting agile procurement for specialty food retailers. Qingdao manufacturers target large-scale agricultural and logistics operations, offering robust, high-capacity containers at higher price points. Qingdao Cnplast stands out for production volume and export readiness, backed by the highest reported online revenue. While Qingdao Zhiyuancheng offers the lowest prices and single-unit ordering, its limited customization and lower revenue signal a transactional rather than strategic partnership model.

FAQs

How to verify bulk produce bin material safety?

Request compliance documentation for FDA 21 CFR §177.1520 and EU Regulation (EU) No 10/2011 for plastic materials in contact with food. Validate resin grade (HDPE #2 or PP #5) and confirm absence of recycled content in direct-contact components unless certified as food-safe.

What is the typical lead time for bulk produce bins?

Standard orders ship within 15–25 days after confirmation. Custom molds add 7–14 days to production timelines. Air freight delivers samples in 5–7 days; sea freight requires 25–35 days depending on destination port.

Can suppliers provide free samples?

Sample availability varies. Some suppliers offer paid samples refundable against future orders. Expect to cover shipping and tooling costs for customized prototypes. Low-MOQ options (e.g., 1–2 pieces) serve as de facto test units for quality assessment.

Are bulk produce bins recyclable?

Yes, most bins are made from recyclable HDPE or PP plastics. Verify resin identification codes and confirm whether the supplier participates in take-back or regrind programs for end-of-life management.

How to negotiate better pricing on bulk produce bins?

Leverage order volume: unit prices typically decrease at 50+, 100+, and 500+ piece thresholds. Consolidate SKUs to reduce setup complexity. Consider FOB terms to control freight costs and expedite delivery schedules.