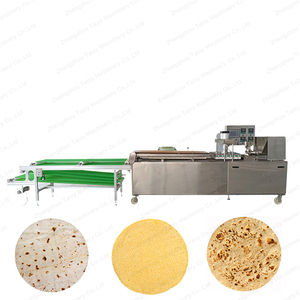

Bulk Roti Making Machine

CN

CN

1/18

1/18

1/16

1/16

1/15

1/15

1/12

1/12

1/20

1/20

1/3

1/3

1/10

1/10

About bulk roti making machine

Where to Find Bulk Roti Making Machine Suppliers?

China leads global manufacturing of industrial-grade bulk roti making machines, with concentrated supplier clusters in Henan and surrounding regions. These areas host specialized mechanical equipment producers leveraging integrated supply chains for grain processing machinery. The presence of mature metal fabrication, automation component suppliers, and food-grade material vendors within close proximity enables efficient production scaling and cost optimization.

Suppliers in this ecosystem benefit from vertically aligned manufacturing capabilities—ranging from sheet metal stamping to control system integration—supporting rapid prototyping and volume production. Buyers gain access to facilities equipped for both standard and customized configurations, with typical lead times ranging from 20–45 days depending on order complexity. Localized sourcing reduces component costs by 15–25% compared to Western alternatives, while established export logistics networks ensure reliable worldwide delivery via sea or air freight.

How to Choose Bulk Roti Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to mitigate risk and ensure performance alignment:

Technical Capability Verification

Confirm suppliers possess in-house engineering teams capable of handling customization requests involving diameter adjustment (typically 150–270mm), output capacity (up to 1,800 pieces/hour), and material compatibility (wheat, millet, maize). Demand technical documentation including motor specifications (power range: 1.5–7.5kW), heating systems (electric/gas options), and compliance with food safety standards such as FDA or EU 1935/2004. While explicit ISO certification is not listed in available data, prioritize suppliers demonstrating consistent quality through high on-time delivery rates (>97%) and verifiable transaction histories.

Production Infrastructure Assessment

Evaluate operational scale using proxy indicators:

- Multiple product listings across automated dough feeding, pressing, rolling, and baking functions indicate diversified production lines

- Offerings spanning $250–$110,000 suggest tiered manufacturing capacity for small-scale to fully automated turnkey systems

- Customization options for shape, size, crust texture, and branding imply advanced tooling and mold design capabilities

Cross-reference these with response time metrics (≤2–4 hours) and reorder rates to assess service reliability and customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services where funds are released post-inspection. Request pre-shipment inspection reports or third-party audits for orders exceeding 10 units. Sample testing is strongly advised—evaluate machine performance over a minimum 8-hour run to verify consistency in thickness, cooking uniformity, and downtime frequency. Confirm packaging suitability for international shipping, particularly moisture resistance and shock absorption for electrical components.

What Are the Best Bulk Roti Making Machine Suppliers?

| Company Name | Location | Verified Type | Main Products | Price Range (USD) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Luohe Quality Mechanical Equipment Co., Ltd. | Henan, CN | Custom Manufacturer | Automatic roti/chapati makers, dough dividers | $780–$8,700 | 97% | ≤2h | $1M+ | 19% |

| SSS Hardware International Trading Co., Ltd. | Unknown, CN | Multispecialty Supplier | Large-scale tortilla/roti systems, pneumatic presses | $4,500–$110,000 | 100% | ≤4h | $800K+ | <15% |

| Henan Paidian Mechanical Equipment Co., Ltd. | Henan, CN | Not specified | Fully automatic chapati machines, baking ovens | $250–$4,756 | 100% | ≤2h | $8K+ | <15% |

| Zhengzhou Taizy Trading Co., Ltd. | Henan, CN | Multispecialty Supplier | Kulcha, pita, crepe, injera machines | $1,200–$6,500 | 100% | ≤3h | $20K+ | 25% |

| GIRNAR MACHINE PRIVATE LIMITED | India | Not specified | Fully automated chapati/roti systems | $7,358 | Not available | ≤25h | Not available | Not available |

Performance Analysis

Luohe Quality and Zhengzhou Taizy stand out due to strong reorder rates (19%, 25%), sub-3-hour response times, and extensive customization offerings. Luohe’s focus on large-scale commercial systems positions it well for high-volume buyers requiring end-to-end automation. SSS Hardware offers the highest price-tier equipment ($110,000), suggesting capability in engineered turnkey solutions, though its low reorder rate may indicate limited after-sales support. Henan Paidian provides entry-level automation at competitive prices ($250), suitable for SMEs or pilot deployments. GIRNAR MACHINE, based in India, presents a regional alternative but lacks transparency in delivery performance and revenue metrics, increasing procurement risk without additional verification.

FAQs

How to verify bulk roti making machine supplier reliability?

Assess reliability through documented on-time delivery records (>97%), response time consistency (≤4 hours), and transaction volume (e.g., $1M+ annual online revenue). Request factory videos or virtual tours to confirm production infrastructure. Validate claims about customization capabilities by reviewing past project examples or requesting CAD drawings for proposed modifications.

What is the typical MOQ and pricing structure?

Minimum Order Quantity (MOQ) is typically 1 set across suppliers, facilitating sample trials. Pricing varies significantly based on automation level: semi-automatic models start at $250, mid-range fully automatic units range from $1,200–$4,500, and high-capacity integrated lines exceed $45,000. Volume discounts are commonly available for orders above 5 sets.

Can suppliers customize machine specifications?

Yes, most suppliers offer customization for diameter (150–270mm), thickness, shape (round, oval, rectangular), output speed, and power source. Additional features include programmable logic controllers (PLCs), non-stick coating types, and branding integration (logo embossing). Lead time for custom units increases by 10–20 days on average.

Do manufacturers provide technical support and after-sales service?

Support availability varies. Top-tier suppliers with high reorder rates typically offer remote troubleshooting, spare parts supply, and operational manuals in English. For critical installations, negotiate inclusion of technician dispatch or training sessions as part of the contract. Confirm warranty terms covering core components like motors, heaters, and control boards (standard duration: 12 months).

How are bulk roti machines packaged and shipped internationally?

Machines are generally packed in wooden crates with foam padding to protect sensitive electrical and mechanical parts. Export-ready packaging includes waterproof wrapping and corner protectors. Shipping methods depend on order size—LCL for single units, FCL for container loads. FOB terms are common; buyers should confirm incoterms, insurance coverage, and import clearance responsibilities prior to shipment.