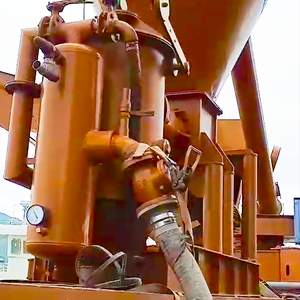

Bulk Unloading Systems

Top sponsor listing

Top sponsor listing

About bulk unloading systems

Where to Find Bulk Unloading Systems Suppliers?

China remains the central hub for bulk unloading systems manufacturing, with key supplier clusters concentrated in Shandong and Guangdong provinces. Shandong, particularly Qingdao, hosts integrated industrial zones specializing in heavy-duty material handling equipment, supported by regional steel production and port logistics infrastructure. This enables cost efficiencies of 15–25% compared to Western suppliers due to proximity to raw materials and streamlined export channels. Guangdong-based manufacturers leverage advanced fabrication techniques and agile supply chains, focusing on automated and stainless-steel configurations for food, chemical, and pharmaceutical applications.

These regions offer vertically aligned production ecosystems—spanning CNC machining, welding, powder coating, and assembly—allowing rapid turnaround for both standard and engineered-to-order systems. Buyers benefit from scalable output, with lead times averaging 30–60 days depending on complexity. The presence of certified engineering teams and modular design platforms supports customization while maintaining structural integrity and operational safety across diverse bulk materials including powders, granules, and agricultural chemicals.

How to Choose Bulk Unloading Systems Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Confirm adherence to international standards such as ISO 9001 for quality management and CE marking for mechanical safety. For hygienic or explosive environments, verify compliance with FDA, ATEX, or GMP where applicable. Evaluate design proficiency through CAD modeling capabilities and experience with load-bearing structures (e.g., I-beam frames, pneumatically sealed hoppers). Request validation documentation for critical components like lifting mechanisms, discharge chutes, and dust control integration.

Production Infrastructure Assessment

Prioritize suppliers with dedicated fabrication facilities exceeding 5,000m² and in-house processing capabilities including laser cutting, robotic welding, and surface treatment. A qualified manufacturer should maintain a minimum workforce of 50+, with engineering staff comprising at least 10% of total personnel to support custom projects. Cross-reference facility size with order volume capacity—suppliers listing over 300 material handling products typically demonstrate established production scalability.

Transaction Reliability & After-Sales Support

Analyze supplier performance metrics: target on-time delivery rates above 97% and response times under 2 hours for prompt communication. Reorder rates above 30% indicate customer satisfaction and product reliability. Where available, review third-party verified transaction histories and insist on formal inspection protocols prior to shipment. Pre-shipment testing—including load tests and operational dry runs—should be standard practice for large-scale or automated systems.

What Are the Best Bulk Unloading Systems Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (Min Order) |

|---|---|---|---|---|---|---|---|

| Solution Technology Qingdao Co., Ltd. | Shandong, CN | Concrete Batching Plant (1041), Dust Collector (434), Conveyors (363) | 100.0% | ≤2h | 50% | Color, material, size, logo, packaging, label, graphic | $1,300–$7,900/set |

| Huizhou Xiewei Machinery Equipment Co., Ltd. | Guangdong, CN | Mixing Equipment (38), Other Chemical Equipment (29), Silos (17) | 100.0% | ≤1h | Not Available | Not Specified | $1,000–$3,000/set |

| MANUFACTURING AIR-BLOWN MATERIALS TAY DO CO.,LTD | Vietnam | Other Construction Machinery (20), Conveyors (8), Silos (2) | Not Available | ≤17h | Not Available | Not Specified | $100,000–$1M/unit or ton |

| Henan Province Modern Crane Co., Ltd. | Henan, CN | Gantry Cranes (180), Bridge Cranes (128), Hoists (71) | 100.0% | ≤2h | Not Available | Not Specified | $9,000–$180,000/set |

Performance Analysis

Solution Technology Qingdao stands out with a high reorder rate (50%) and comprehensive customization options, indicating strong client retention and design flexibility. Huizhou Xiewei excels in responsiveness (≤1h) and competitive pricing, catering to mid-range industrial needs in chemical and agricultural sectors. MANUFACTURING AIR-BLOWN MATERIALS TAY DO CO.,LTD targets large-scale infrastructure projects with capital-intensive systems priced per unit or ton, though slower response times suggest potential communication delays. Henan Province Modern Crane leverages crane integration expertise for container tilters and truck unloaders, serving logistics and grain handling industries with robust, high-capacity solutions. Buyers seeking automation and dust-free operation should prioritize suppliers offering full system integration with conveyors and silos.

FAQs

What certifications should bulk unloading system suppliers have?

Essential certifications include ISO 9001 for quality management and CE for mechanical and electrical safety. Additional requirements may include ATEX for explosive atmospheres, FDA compliance for food-grade contact surfaces, and local regulatory approvals depending on the destination market.

What is the typical MOQ and lead time?

Minimum order quantities are commonly set at 1 set for standard models. Custom systems may require higher commitments based on engineering input. Lead times range from 30 days for off-the-shelf units to 60+ days for engineered solutions involving structural modifications or automation integration.

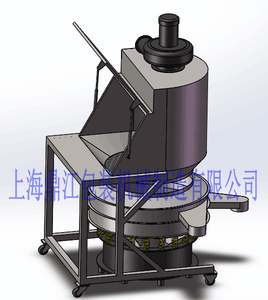

Can suppliers customize bulk unloading systems?

Yes, leading suppliers offer customization in frame material (carbon steel, stainless steel), hopper geometry, lifting mechanisms (pneumatic, hydraulic), discharge interfaces, and integration with downstream conveyors. Some provide branding options including color, labeling, and packaging configuration.

How to verify supplier credibility?

Validate certifications through issuing bodies, request factory audit reports or video tours, and analyze historical transaction data including on-time delivery and customer feedback. Third-party inspection services can verify product conformity before shipment.

Are samples available for bulk unloading systems?

Due to size and function, full-system sampling is uncommon. However, suppliers may provide component prototypes (e.g., discharge spout, frame section) or 3D models for design approval. Pilot orders for single units serve as functional references for larger procurement.