Button Badge Maker Near Me

About button badge maker near me

Where to Find Button Badge Maker Suppliers?

China is the global epicenter for button badge maker manufacturing, with key production clusters in Zhejiang, Guangdong, and Jiangsu provinces. These regions host vertically integrated supply chains that combine precision tooling, metal stamping, and assembly operations within compact industrial zones. Yiwu and Dongguan serve as primary hubs for small-format badge equipment, offering rapid prototyping and low-volume production runs ideal for DIY kits and promotional product suppliers.

The concentration of component manufacturers—such as die-cut mold producers, pin back suppliers, and plastic dome laminators—within 50km radii enables agile production cycles. This proximity reduces material procurement time by up to 40% compared to decentralized markets. Buyers benefit from scalable output options: manual press machines can be delivered within 7–10 days, while semi-automatic systems have lead times of 25–35 days. Cost efficiency is further enhanced by localized sourcing, with finished units priced 20–35% below equivalent Western-made models.

How to Choose Button Badge Maker Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compatibility

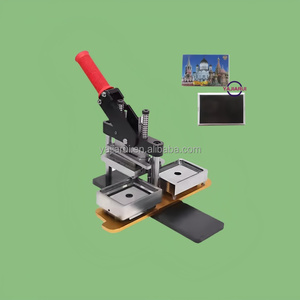

Verify machine compatibility with standard badge sizes (25mm, 32mm, 58mm, 75mm) and formats (round, square, rectangular, custom shapes). Confirm support for both plastic mylar sealing and cold-lamination processes. For high-volume users, assess pneumatic or semi-automatic models capable of producing 300–500 units per hour. Manual presses should include alignment guides and dual-stage pressing mechanisms to ensure consistent encapsulation.

Production Capacity Verification

Evaluate infrastructure indicators:

- Minimum factory area exceeding 1,000m² for sustained output

- In-house tooling capabilities for mold customization

- Integration of quality control checkpoints during assembly

Cross-reference online revenue metrics (e.g., $100,000+ annual digital sales) with on-time delivery rates above 97% to validate operational stability.

Transaction Security & After-Sales Support

Prioritize suppliers offering verifiable response times under 3 hours and documented reorder rates above 15%, indicating customer retention. Confirm availability of English-language technical documentation and spare parts inventory. Use secure payment frameworks that allow inspection prior to final settlement. Request sample units to evaluate build quality, ease of use, and seal integrity before scaling orders.

What Are the Best Button Badge Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Button Making Machines, Heat Press Machine | US $120,000+ | 100% | ≤3h | 17% | 1 set | $39–$300 |

| Foshan Yajiarui Machinery Co., Ltd. | Filling & Sealing Machines, Multi-Function Packaging | US $130,000+ | 100% | ≤1h | <15% | 1 set | $59–$2,999 |

| Dongguan Dinglian Machinery Co., Ltd. | Heat Press, Button Making Machines, Transfer Equipment | US $220,000+ | 100% | ≤2h | <15% | 1 set | $38–$625 |

| Yiwu Rubysub Digital Graphic Co., Ltd. | Decorative Objects, Heat Press, Office Accessories | US $150,000+ | 97% | ≤5h | 17% | 1 piece | $25–$627 |

| Yiwu Chuxin Technology Co., Ltd. | Button Making Machines, Badge Holders, Rulers | US $10,000+ | 84% | ≤1h | 20% | 1 piece | $15–$49 |

Performance Analysis

Dongguan Dinglian and Yancheng Stik Pro demonstrate strong technical specialization with diversified product lines including heat transfer systems, enabling integrated production workflows. Foshan Yajiarui offers industrial-grade solutions, exemplified by its $2,999 semi-automatic pneumatic system—suitable for commercial badge fulfillment centers requiring high throughput. Yiwu-based suppliers focus on entry-level and novelty formats (heart-shaped, star-shaped), catering to craft and retail segments with piece-level ordering. Notably, Yiwu Chuxin provides the lowest price point ($15/unit) but has a significantly lower on-time delivery rate (84%), suggesting potential fulfillment risks for time-sensitive projects.

FAQs

What are typical MOQs for button badge makers?

Most suppliers offer minimum order quantities of 1 piece or 1 set, particularly for manual press machines. Bulk pricing becomes advantageous at 10+ units, with discounts averaging 10–25% depending on configuration complexity.

What is the average lead time for shipment?

Standard manual machines ship within 3–7 days after payment confirmation. Customized or automated systems require 20–35 days for production and testing. Air freight delivers internationally in 5–10 days; sea freight takes 25–40 days depending on destination port.

Can suppliers customize badge maker molds?

Yes, manufacturers with in-house CNC tooling can produce custom dies for non-standard shapes (e.g., logos, animal silhouettes). Lead time for mold development ranges from 7–14 days, with costs varying between $150–$500 based on intricacy and size.

Are certifications available for export compliance?

While not universally standardized, some suppliers provide CE marking upon request for electrical components in automated models. For manual machines, compliance relies on mechanical safety design. Buyers should independently verify adherence to local consumer product regulations, especially regarding pinch-point protection and material safety (RoHS).

Do suppliers offer spare parts and maintenance support?

Leading suppliers maintain inventories of replacement pins, sealing dies, and pressure pads. Technical diagrams and instructional videos are typically provided. Long-term service agreements are uncommon, but component-level repairs are feasible due to modular designs.