Button Maker Ebay

About button maker ebay

Where to Find Button Maker Suppliers?

China remains the dominant hub for button maker manufacturing, with key production clusters in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated supply chains that specialize in small-format metal forming and manual press machinery. Yancheng in Jiangsu and Yiwu in Zhejiang have emerged as specialized centers for badge and button-making equipment, offering compact, hand-operated models ideal for craft businesses and small-scale customization operations.

The industrial ecosystems in these zones support rapid prototyping and low-to-mid volume production, with access to precision die-cutting tools, magnetic backing lines, and standardized mold sets. Suppliers benefit from localized component sourcing—such as zinc alloy dies, steel pressing plates, and plastic casings—reducing lead times by 20–30% compared to offshore alternatives. Average production cycles range from 15–30 days for standard orders, with express processing available for pre-configured models.

How to Choose Button Maker Suppliers?

Effective supplier selection requires verification across three core dimensions:

Technical Capability Assessment

Confirm machine specifications align with intended use: diameter compatibility (commonly 25mm, 38mm, 50mm, 58mm, or 75mm), material thickness tolerance, and force pressure (typically 2–5 tons for manual models). Suppliers should provide technical schematics and operational manuals. For pneumatic or semi-automated units, verify air pressure requirements and cycle time efficiency.

Production & Quality Controls

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area of 1,000m² for stable output

- In-house tooling capacity for mold modification

- On-site quality checks including pressure testing and alignment calibration

Cross-reference on-time delivery rates (target ≥95%) and response times (ideally ≤2 hours) as indicators of operational discipline. Prioritize suppliers with documented QC processes and product traceability systems.

Transaction Security & Customization Support

Utilize secure payment methods such as escrow services for initial transactions. Analyze supplier performance via verifiable metrics: reorder rates below 20% suggest limited customer retention, while rates above 20% may indicate niche specialization or after-sales satisfaction. For custom branding or OEM requests, confirm packaging, labeling, and logo printing capabilities. Some suppliers offer design file templates and pre-shipment sample validation.

What Are the Best Button Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ | Price Range (per set) |

|---|---|---|---|---|---|---|---|

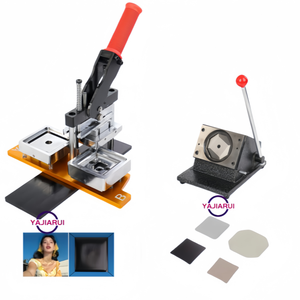

| Foshan Yajiarui Machinery Co., Ltd. | Filling, Sealing, Capping, Vacuum Packing Machines | US $130,000+ | 100% | <15% | ≤1h | 1 set | $59–319 |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Button Making Machines, Heat Press Machines | US $120,000+ | 100% | 17% | ≤3h | 1 set | $60–620 |

| Jiangxi Mide Industrial Co., Ltd. | Custom Badge Makers, Pneumatic Presses | US $380,000+ | 96% | <15% | ≤3h | 1 piece/set | $158–1,380 |

| Yiwu Chuxin Technology Co., Ltd. | Button Making Kits, Office Supplies | US $10,000+ | 85% | 20% | ≤1h | 1 piece | $16–49 |

| Quanzhou Kari Appliance Co., Ltd. | Button Makers, Heat Presses, Drinkware | US $10,000+ | 92% | <15% | ≤5h | 1 piece | $25–260 |

Performance Analysis

Foshan Yajiarui and Yancheng Stik Pro demonstrate strong reliability with 100% on-time delivery and competitive pricing for entry-level square and rectangular models. Jiangxi Mide stands out for high-end pneumatic systems, targeting commercial users requiring durability and customization—reflected in its premium pricing and largest online revenue. Yiwu Chuxin offers the lowest price points, suitable for hobbyists, though its 85% delivery rate warrants closer shipment monitoring. Quanzou Kari provides diverse product bundling options but has slower average response times. Buyers seeking fast turnaround and technical responsiveness should prioritize suppliers with sub-3-hour response windows and documented customization workflows.

FAQs

What is the typical MOQ for button maker machines?

Most suppliers list a minimum order quantity of 1 set or 1 piece, particularly for manual press models. Bulk discounts are commonly available starting at 10 units. Pneumatic or industrial-grade units may require higher MOQs depending on configuration.

How long does production and shipping take?

Standard lead time ranges from 15–30 days post-payment confirmation. Air freight delivery adds 5–10 days internationally; sea freight requires 25–40 days depending on destination port. Expedited processing (7–14 days) is offered by select suppliers for ready-stock units.

Can button makers be customized with private labels?

Yes, many suppliers support OEM services including custom color finishes, branded housings, user manuals, and packaging. Minimum volumes for branding vary—typically 50–100 units. Graphic design assistance is occasionally provided upon request.

Are samples available before bulk ordering?

Sample availability depends on model complexity. Simple manual kits are often shipped as samples at near-production cost. For automated or pneumatic models, suppliers may require partial payment covering material and labor. Sampling lead time averages 7–15 days.

What materials are used in button maker construction?

Common materials include cast iron frames for stability, hardened steel dies for compression, and zinc alloy molds for dimensional accuracy. Handles are typically powder-coated steel or reinforced ABS plastic. Pneumatic versions incorporate aluminum cylinders and solenoid valves compliant with industrial safety standards.