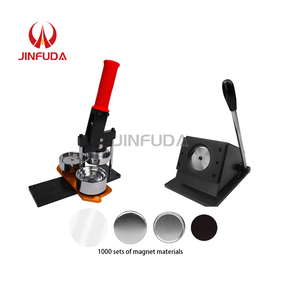

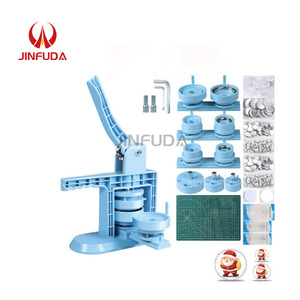

Button Maker Machine 3 Inch

About button maker machine 3 inch

Where to Find Button Maker Machine 3 Inch Suppliers?

China is the global epicenter for button maker machine manufacturing, with key production clusters in Zhejiang, Jiangxi, and Fujian provinces. These regions host vertically integrated supply chains specializing in manual and semi-automatic badge production equipment. Yiwu, a major hub in Zhejiang, supports over 200 machinery suppliers focused on small-format promotional product lines, including 3-inch button makers. The concentration enables rapid prototyping, low-cost tooling, and efficient component sourcing—particularly for aluminum molds, plastic dies, and lever-press mechanisms.

Suppliers leverage localized access to CNC machining workshops, metal stamping facilities, and packaging vendors within 50km radii, reducing lead times by up to 40% compared to offshore alternatives. Average production cycles range from 7–15 days for standard models, with express fulfillment options available for single-unit orders. Buyers benefit from flexible MOQs (as low as 1 piece), competitive pricing due to economies of scale, and strong customization capabilities across mold size, handle design, and branding elements.

How to Choose Button Maker Machine 3 Inch Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compatibility

Confirm machine compatibility with 75mm (3-inch) components, including front domes, back pins, and sealing rings. Verify whether the system supports interchangeable dies for multi-size production (e.g., 1.25", 2.25", 3"). Prioritize models with precision alignment guides and dual-stage pressing mechanisms to minimize material waste during high-volume runs.

Production Capacity & Operational Metrics

Assess supplier performance using verifiable metrics:

- On-time delivery rate exceeding 95%

- Average response time under 3 hours

- Reorder rate above 20% indicating customer retention

- Minimum of 50 active product listings signaling market presence

Cross-reference these indicators with revenue benchmarks—suppliers reporting over US $30,000 in annual online sales typically maintain dedicated quality control teams and inventory management systems.

Customization and Compliance

Evaluate capability for OEM/ODM services such as color variation, logo engraving, packaging labeling, and instructional manuals in multiple languages. While formal certifications like CE or ISO 9001 are not universally held among micro-enterprises, prioritize suppliers who document internal QC procedures and offer sample testing prior to bulk ordering.

What Are the Best Button Maker Machine 3 Inch Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Jiangxi Mide Industrial Co., Ltd. | Jiangxi, CN | Button Making Machines, Customization Solutions | US $380,000+ | 96% | ≤3h | <15% | 1 set/piece | $219–719 |

| Yiwu Chuxin Technology Co., Ltd. | Zhejiang, CN | Button Making Machines (106) | US $10,000+ | 84% | ≤1h | 16% | 1 piece | $16–119 |

| Yiwu Wantu Machinery Equipment Co., Ltd. | Zhejiang, CN | Button Making Machines (229) | US $30,000+ | 97% | ≤3h | 19% | 1 piece/set | $20–199 |

| Ningbo Yfd Machinery Manufacturing Co., Ltd. | Zhejiang, CN | Button Making Machines (43) | US $10,000+ | 100% | ≤2h | 28% | 1 piece | $20–140 |

| Fujian Auplex Appliance Co., Ltd. | Fujian, CN | Button Making Machines (125) | US $200,000+ | 97% | ≤6h | 17% | 1 piece/set | $36–345 |

Performance Analysis

Jiangxi Mide and Fujian Auplex represent higher-tier suppliers with substantial revenue volumes and diversified product engineering, suitable for buyers seeking premium builds and customization depth. Yiwu-based companies (Chuxin, Wantu, YFD) emphasize affordability and fast turnaround, with sub-$100 entry points ideal for startups and craft businesses. Notably, Ningbo YFD achieves a 100% on-time delivery rate and 28% reorder rate, suggesting robust order management despite moderate online revenue. Yiwu Wantu leads in catalog breadth with 229 listed button machine variants, reflecting specialization and inventory readiness.

FAQs

What materials are used in 3-inch button maker machines?

Most units are constructed from die-cast zinc, aluminum alloy, or reinforced plastic frames. Critical components like pressing dies and pin setters are typically made from hardened steel or anodized aluminum to ensure dimensional accuracy across repeated use.

What is the typical lead time for bulk orders?

Standard lead times range from 10–20 days after deposit confirmation. Express production (7–10 days) is often available for quantities under 50 sets, depending on factory workload and component availability.

Can suppliers provide free samples?

Sample policies vary. Some suppliers offer paid samples refundable against future orders, while others charge full cost for single-piece shipments. Free samples are rarely offered unless accompanied by a confirmed purchase agreement.

Do button maker machines support international component standards?

Yes, most 3-inch (75mm) models accommodate globally sourced accessories, including magnetic backs, safety pins, and adhesive bases. Buyers should verify compatibility with local consumables before procurement to avoid interoperability issues.

How to initiate customization requests?

Submit detailed specifications covering desired mold size, frame color, handle length, logo placement, and packaging format. Leading suppliers respond within 24–48 hours with CAD sketches or prototype timelines, especially when supported by advance sampling deposits.