Button Making Machine Hobby Lobby

About button making machine hobby lobby

Where to Find Button Making Machine Suppliers?

China remains the dominant hub for button making machine production, with key manufacturing clusters in Zhejiang, Fujian, and Henan provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable output for both manual hobbyist models and industrial-grade equipment. Ningbo and Taizhou in Zhejiang specialize in precision mechanical assembly, offering compact, user-friendly machines ideal for DIY and small-batch applications. Quanzhou in Fujian leverages its home appliance manufacturing base to produce hybrid models integrating heat press and badge-making functionalities. Henan’s agricultural machinery suppliers have diversified into servo-driven automatic button machines, reflecting cross-sector technological adaptation.

The regional ecosystems enable cost efficiencies through localized component sourcing—steel molds, pressing dies, and plastic feed systems are produced within 50km of final assembly plants. This integration reduces lead times to 15–30 days for standard orders and supports low minimum order quantities (MOQs), often as low as one piece. Buyers benefit from flexible configurations, including round, square, and rectangular button formats (25mm to 60mm), with pricing influenced by automation level, material compatibility, and force mechanism (manual, pneumatic, or electric servo).

How to Choose Button Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compatibility

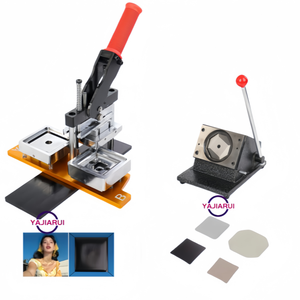

Confirm machine compatibility with required button types (pin-backed, magnet, epoxy dome) and substrate materials (metal, plastic, paper). Manual models typically range from $30–$100 and suit hobbyist use, while servo-automated systems exceed $1,800 for continuous production. Verify mold interchangeability and tooling availability for multi-size operations. For commercial deployment, demand specifications on pressing force (measured in kN), cycle time, and die longevity (rated in cycles).

Production and Quality Assurance

Assess supplier capabilities through the following indicators:

- Minimum of 30+ active product listings in button machine category indicating market specialization

- In-house design or engineering capacity, particularly for custom mold development

- On-time delivery performance exceeding 90% as a proxy for logistics reliability

- Reorder rates above 15% suggest customer retention and product satisfaction

While formal certifications (ISO 9001, CE) are infrequently cited in this segment, consistent online revenue (>$10,000 annually) and sub-4-hour response times correlate with operational maturity. Request digital documentation such as assembly diagrams, maintenance manuals, and video demonstrations to validate build quality.

Procurement and Transaction Safeguards

Prioritize suppliers offering transaction protection mechanisms such as verified payment escrow. Conduct sample testing to evaluate ease of operation, alignment accuracy, and structural durability under repeated use. Negotiate terms covering spare parts availability (especially dies and pins) and after-sales technical guidance. For bulk orders, confirm packaging standards and export compliance, particularly for electrical components subject to destination-market regulations.

What Are the Best Button Making Machine Suppliers?

| Company Name | Main Products (Listings) | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Button Making Machines (944), Heat Press (36) | $39–620 | 1 set | 100.0% | ≤3h | US $130,000+ | 17% |

| Taizhou My Button Machine Co., Limited. | Button Making Machines (125), Fridge Magnets (102) | $28–3,950 | 1 piece/box | 78.0% | ≤10h | US $40,000+ | <15% |

| Ningbo Yfd Machinery Manufacturing Co., Ltd. | Button Making Machines (43), Paper Trimmer (4) | $90–140 | 1 piece | 100.0% | ≤3h | US $10,000+ | <15% |

| Quanzhou Kari Appliance Co., Ltd. | Heat Press (227), Button Machines (34) | $40–260 | 1 piece | 92.0% | ≤4h | US $10,000+ | <15% |

| Henan Growing Mechanical Equipment Co., Ltd. | Servo Button Machines ($185–265), Automatic Systems ($2,000+) | $185–2,468 | 1 set | 100.0% | ≤7h | US $8,000+ | 66% |

Performance Analysis

Yancheng Stik Pro leads in product diversity and transaction volume, supported by perfect on-time delivery and fast response times, making it a reliable choice for international buyers. Its high listing count (944) reflects deep specialization in button press systems. Taizhou My Button Machine offers the widest price spectrum, catering to both entry-level and semi-automated industrial needs, though lower reorder rates and slower response times indicate potential service variability. Ningbo Yfd and Quanzhou Kari provide competitively priced manual models suitable for hobbyist distribution channels. Notably, Henan Growing Mechanical exhibits the highest reorder rate (66%), suggesting strong end-user satisfaction with its servo-based automation line despite higher entry costs.

FAQs

What is the typical MOQ for button making machines?

Most suppliers offer a minimum order quantity of 1 piece or set, especially for manual and desktop models. Bulk pricing typically applies at 10+ units, with customization options available beyond 50 units.

How long does production and shipping take?

Standard orders are processed within 7–15 days. Air freight delivers within 5–10 days globally; sea freight takes 25–40 days depending on destination. Customized machines may require an additional 10–20 days for tooling adjustments.

Can suppliers customize button size and shape?

Yes, many suppliers support mold customization for non-standard sizes (e.g., rectangular 80x53mm) and specialized backing types. Lead time for custom molds ranges from 10–25 days, with tooling costs varying between $100–$500 depending on complexity.

Are spare parts and technical support included?

Spare dies, pins, and pressing plates are available upon request. Technical support is typically provided via digital channels (email, video guide). Long-term service agreements are uncommon, so buyers should secure spare components during initial procurement.

Do button making machines comply with safety standards?

While most machines lack formal CE or ISO certification, reputable suppliers design units with mechanical safety stops and ergonomic handles. Electrical models should be evaluated for insulation and grounding compliance prior to commercial deployment in regulated markets.