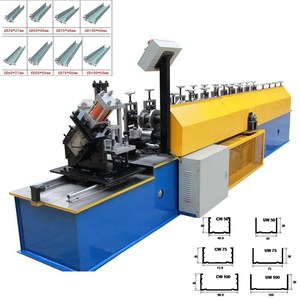

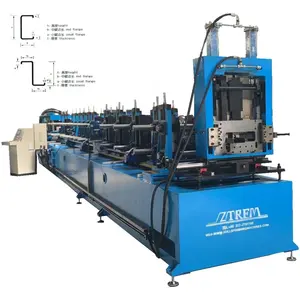

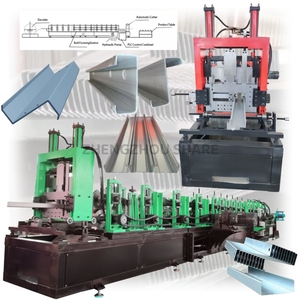

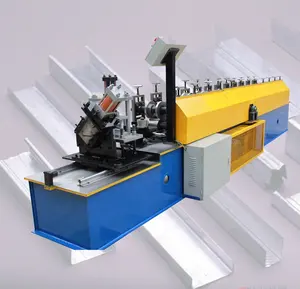

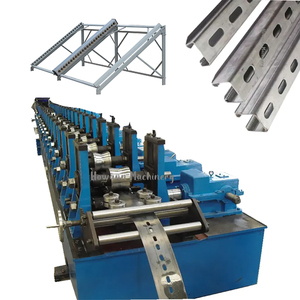

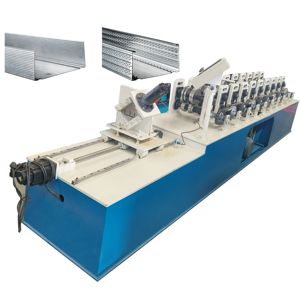

C U W Channel Roll Forming Machine

Top sponsor listing

Top sponsor listing

CN

CN

About c u w channel roll forming machine

Where to Find C U W Channel Roll Forming Machine Suppliers?

China remains the central hub for manufacturing C U W channel roll forming machines, with key production clusters concentrated in Hebei and Henan provinces. These regions host vertically integrated industrial ecosystems specializing in light gauge steel framing and metal profile machinery. Botou City in Hebei is particularly renowned for its concentration of roll forming equipment manufacturers, supported by localized supply chains for precision rollers, hydraulic systems, and decoilers.

The clustering enables significant cost efficiencies—suppliers benefit from proximity to raw material sources and component fabricators, reducing production lead times by 20–30% compared to non-specialized regions. Facilities typically operate on a scale of 3,000–25,000+ m², supporting batch production capacities of 15–30 units per month. This infrastructure allows suppliers to fulfill both small-volume custom orders and large-scale export contracts within standard delivery windows of 30–45 days.

How to Choose C U W Channel Roll Forming Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international quality standards such as ISO 9001 for quality management and CE marking for mechanical safety compliance. Machines destined for North American or European markets must meet regional electrical and operational safety codes. Request documentation on roller hardness (typically HRC 58–62), shaft diameter tolerances (±0.02mm), and motor power specifications to validate performance claims.

Production Capability Audits

Assess core manufacturing competencies through the following criteria:

- In-house CNC machining and welding capabilities for roller die fabrication

- Dedicated R&D departments capable of generating CAD drawings and process flow diagrams

- Minimum factory area exceeding 3,000m² to support assembly lines and testing zones

Cross-reference online transaction histories with on-time delivery rates above 97% and reorder rates exceeding 30% as indicators of reliability and customer satisfaction.

Customization & Quality Control

Leading suppliers offer full customization including adjustable forming speeds (10–40m/min), variable material thickness ranges (0.4–3.0mm), and multi-profile compatibility (C, U, W, CD, UD channels). Confirm implementation of pre-shipment inspection protocols, including no-load operation tests (minimum 4 hours) and dimensional accuracy checks using laser gauges. Hydraulic cutting systems should be tested for cycle durability (≥10,000 operations).

What Are the Best C U W Channel Roll Forming Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Botou Huayang Roll Forming Machinery Co., Ltd. | Hebei, CN | Tile Making Machinery (4903); Steel Frame & Purlin Machines (83) | US $260,000+ | 100% | ≤2h | 33% | $6,500–$30,000 | Material size, mold design, hydraulic system, packaging, label, width, color, layer |

| Cangzhou Zhongtuo International Trade Co., Ltd. | Hebei, CN | Steel Frame & Purlin Machines, Keel Makers | US $4,700,000+ | 100% | ≤2h | 37% | $9,999–$35,000 | Adjustable pressure, yield strength settings, automatic operation modes, multi-size tooling |

| Henan Randro Machinery Equipment Co., Ltd. | Henan, CN | Steel Frame & Purlin Machines (163); Tile Making Machinery (565) | US $350,000+ | 100% | ≤2h | 57% | $5,600–$27,000 | Roller configuration, conveyor type, labeling, graphic dimensions, metal thickness |

| Hebei Ironstar Industry Co., Ltd. | Hebei, CN | Tile Making Machinery (4077); Steel Frame & Purlin Machines (905) | US $80,000+ | 100% | ≤2h | <15% | $7,000–$12,500 | Limited customization; focus on drywall and guardrail variants |

Performance Analysis

Botou Huayang and Cangzhou Zhongtuo demonstrate strong technical versatility with broad product portfolios and high customization capacity. Notably, Henan Randro stands out with a 57% reorder rate—the highest among listed suppliers—indicating superior post-sale service and machine reliability. While Hebei-based firms dominate output volume, Henan suppliers exhibit faster innovation cycles in solar strut and multi-function line development. All top-tier suppliers maintain 100% on-time delivery records, with response times consistently under two hours, enabling rapid quotation and design iteration.

FAQs

What materials can C U W channel roll forming machines process?

Standard machines handle galvanized steel coils (GI/PPGI) with thicknesses ranging from 0.4mm to 3.0mm and yield strengths between 235–550 MPa. High-end models support aluminum and pre-painted steel with adjusted forming speeds and roller clearances.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 set. Lead time averages 30–45 days after deposit confirmation, including manufacturing, testing, and packaging. Expedited builds may reduce timelines to 20 days at additional cost.

Do suppliers offer installation and training support?

Most suppliers provide remote guidance via video and manuals. On-site commissioning and operator training are available upon request, typically billed at $150–$200/day plus travel expenses. Some include basic training in premium packages.

Can machines produce multiple profiles without tool change?

Yes, select suppliers offer "multi-in-one" or "two-in-one" configurations where a single line produces C, U, and W channels via adjustable rollers and programmable logic controllers (PLC). These systems require higher initial investment but reduce long-term changeover downtime.

How are machines packaged for international shipping?

Machines are disassembled into major components (decoiler, forming station, cutoff unit, runout table), wrapped in anti-corrosion film, secured on wooden pallets, and enclosed in fumigation-free plywood crates compliant with ISPM 15 standards. Full container load (FCL) shipments optimize freight costs for bulk orders.