Cap Maker Machine

About cap maker machine

Where to Find Cap Maker Machine Suppliers?

China remains the global hub for cap maker machine manufacturing, with key supplier clusters located in Guangdong, Zhejiang, and Shandong provinces. These regions host vertically integrated production ecosystems that combine precision engineering with textile machinery expertise. Guangzhou and Taizhou are emerging as specialized centers for automated headwear processing equipment, supported by local supply chains for molds, heating elements, and pneumatic systems. Proximity to fabric and accessory suppliers enables rapid prototyping and reduced component lead times.

The industrial clusters offer scalable production capacity, with facilities averaging 2,000–5,000m² dedicated to cap machinery assembly. This infrastructure supports both standard model output and customized automation integration. Buyers benefit from localized sourcing of critical subsystems—such as steam boilers, pressure controls, and programmable logic controllers (PLCs)—reducing system integration costs by 15–25%. Typical advantages include MOQ flexibility (from single units to container loads), lead times of 15–30 days for ready-to-ship models, and direct access to OEM/ODM engineering teams for functional modifications.

How to Choose Cap Maker Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm adherence to international electrical and mechanical safety standards, particularly CE marking for European markets. Machines utilizing steam or high-pressure systems must comply with pressure vessel regulations. Verify inclusion of core components such as PID temperature controllers, stainless steel platens, and energy-efficient heating systems. Request test reports on cycle durability (minimum 10,000 cycles) and thermal consistency (±2°C tolerance).

Production Capability Verification

Assess supplier infrastructure through documented evidence:

- Minimum factory area of 1,000m² indicating dedicated production lines

- In-house design capability for mold customization (hat size, curvature, visor shape)

- Integration of CNC-machined tooling and automated clamping mechanisms

Cross-reference on-time delivery performance (target ≥98%) and reorder rates (>30% indicates strong customer retention) as proxies for reliability and product satisfaction.

Procurement Risk Mitigation

Utilize secure payment frameworks such as escrow services until post-delivery inspection is completed. Prioritize suppliers offering sample testing under real operating conditions. Evaluate responsiveness (target ≤12 hours) and multilingual support for smoother communication. Confirm packaging suitability for long-distance shipping, including moisture barriers and shock-absorbing frames.

What Are the Best Cap Maker Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Taizhou Sunsew Trading Co., Ltd. | Zhejiang, CN | Cap Making Machines, Textile Machine Parts | US $20,000+ | 94% | ≤12h | 16% | 5 | $18–$4,300 |

| Zhengzhou Pindu Commercial And Trading Co., Ltd. | Henan, CN | Cap Ironing Machines, Food Processing Equipment | US $120,000+ | 98% | ≤2h | <15% | 5 | $150–$999 |

| Qingdao Tianwo Trading Co., Ltd. | Shandong, CN | Cap Making Machines, Webbing Buckles | US $3,000+ | 100% | ≤2h | 42% | 5 | $400–$2,700 |

| Guangzhou Capable Machinery Co., Ltd. | Guangdong, CN | Cap Making Machines, Cloth Cutting Equipment | US $10,000+ | 100% | ≤5h | 37% | 5 | $1,200–$4,000 |

| Zhecheng Hong Xin Machinery Factory | Henan, CN | Automatic Cap Steam Ironing Machines | US $640,000+ | 100% | ≤2h | <15% | 5 | $800–$1,300 |

Performance Analysis

Suppliers like Qingdao Tianwo and Guangzhou Capable demonstrate strong customer loyalty with reorder rates of 42% and 37%, respectively, indicating high product satisfaction. Zhecheng Hong Xin Machinery Factory leads in online transaction volume (over US $640,000), reflecting robust market demand for its compact, store-ready models priced between $800–$1,300. All top-tier suppliers maintain 100% on-time delivery records, with response times under five hours—critical for resolving technical queries during commissioning. Guangdong- and Zhejiang-based manufacturers specialize in full-cycle cap forming systems, while Henan suppliers focus on entry-level ironing and shaping units suitable for small workshops. For high-volume buyers, prioritize partners with in-house mold fabrication and PLC programming capabilities to ensure seamless integration into existing production lines.

FAQs

What certifications should cap maker machine suppliers have?

Essential certifications include CE for EU compliance and ISO 9001 for quality management. Machines with electrical heating elements should meet IEC 60204-1 safety standards. While not always provided upfront, request conformity declarations or test summaries from accredited labs.

What is the typical lead time for cap making machines?

Standard models are typically shipped within 15–20 days after order confirmation. Custom configurations involving multi-head setups or digital control upgrades may require 30–45 days. Air freight reduces delivery time to 5–7 days internationally, while sea freight averages 25–35 days depending on destination port.

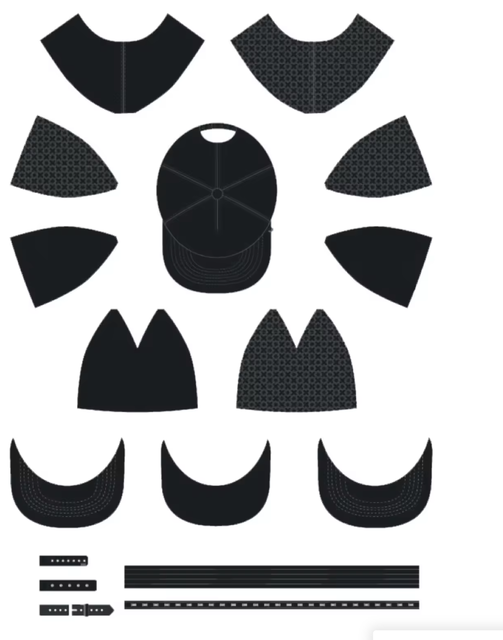

Can suppliers customize cap machines for specific hat types?

Yes, most established suppliers offer mold customization for baseball caps, snapbacks, trucker hats, and flat visors. Modifications include adjustable platen curvature, programmable dwell time, and dual-zone temperature control. Provide physical samples or CAD drawings for accurate replication.

What is the minimum order quantity (MOQ)?

MOQ varies by model: standalone ironing units often allow single-unit orders, while fully automated systems may require one set. Bulk pricing applies at 5+ units for entry-level models and 2+ sets for high-capacity machines.

Do suppliers provide installation and training support?

Many suppliers offer remote setup guidance via video call. Some include instructional manuals, wiring diagrams, and troubleshooting checklists. On-site technician deployment is available upon request but typically incurs additional charges. Confirm pre-shipment testing (burn-in cycles) to minimize field issues.