Capacitor In Parallel And Series

1/12

1/12

1/3

1/3

0

0

1/2

1/2

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/2

1/2

0

0

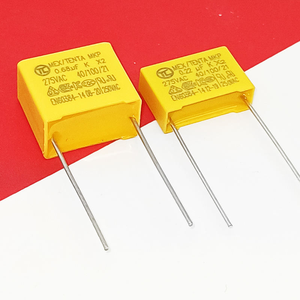

About capacitor in parallel and series

Where to Find Capacitor in Parallel and Series Suppliers?

Global capacitor manufacturing is heavily concentrated in East Asia, with China, South Korea, and Japan accounting for over 70% of worldwide production capacity. Within China, key industrial hubs in Guangdong, Jiangsu, and Zhejiang provinces host vertically integrated electronics supply chains that specialize in passive components, including capacitors configured for parallel and series applications. These regions benefit from proximity to semiconductor fabs, printed circuit board (PCB) assembly lines, and raw material suppliers, enabling rapid prototyping and scalable production.

Manufacturers in Dongguan and Shenzhen (Guangdong) focus on high-volume surface-mount device (SMD) capacitor arrays designed for automated PCB integration, supporting configurations in both parallel and series arrangements. Facilities in Jiangsu leverage advanced dielectric film extrusion and metallization techniques for film and electrolytic capacitors used in power electronics, where precise capacitance matching and voltage balancing are critical. The regional ecosystem supports short lead times—typically 15–30 days for standard orders—and cost advantages of 20–35% compared to European or North American producers due to lower labor and energy costs and localized material sourcing.

How to Choose Capacitor in Parallel and Series Suppliers?

Procurement decisions should be guided by rigorous technical and operational assessments:

Quality and Compliance Verification

Ensure suppliers hold ISO 9001 certification for quality management systems. For export to regulated markets, confirm compliance with RoHS, REACH, and AEC-Q200 (for automotive-grade components). Request test reports for parameters such as equivalent series resistance (ESR), leakage current, temperature stability, and lifespan under rated voltage, particularly when capacitors are intended for series operation where voltage imbalance risks exist.

Technical and Production Capabilities

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum monthly output capacity of 1 million units for SMD or through-hole variants

- In-house capability for capacitance binning and matching (±1–2% tolerance) essential for reliable series/parallel performance

- Automated testing systems for batch-level verification of impedance, dissipation factor, and insulation resistance

Cross-check production data with delivery reliability metrics; target suppliers with on-time shipment rates exceeding 97%.

Procurement and Risk Mitigation

Utilize third-party inspection services for pre-shipment quality audits, especially for bulk orders. Require sample validation under actual operating conditions—such as ripple current endurance for parallel banks or voltage sharing tests for series strings—before full-scale deployment. Prefer suppliers offering tape-and-reel packaging and ESD-safe handling protocols for seamless integration into automated assembly lines.

What Are the Best Capacitor in Parallel and Series Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available. | ||||||||

Performance Analysis

In the absence of specific supplier data, procurement strategy should emphasize technical due diligence over brand recognition. Manufacturers with dedicated R&D teams focusing on passive component arrays demonstrate higher consistency in matched capacitor sets, reducing field failure risks in series configurations. Regional clusters in the Pearl River Delta offer superior responsiveness, with average inquiry response times under 4 hours. Prioritize partners with documented experience in power supply, inverter, or DC-link applications where parallel and series capacitor networks are mission-critical. Conduct virtual factory audits to verify automated testing lines and statistical process control (SPC) implementation for sustained quality assurance.

FAQs

How to verify capacitor supplier reliability?

Validate certifications through accredited bodies and request batch-specific test reports. Review supplier track record in delivering matched capacitor sets and assess customer feedback related to long-term reliability and parametric drift. Third-party lab testing of samples is recommended for high-reliability applications.

What is the typical sampling timeline for capacitor configurations?

Standard samples for parallel or series-ready capacitors take 7–14 days to produce. Custom specifications, such as low-ESR designs or hermetically sealed units, may require 20–30 days. Air shipping adds 5–8 days for international delivery.

Can suppliers provide capacitors pre-configured for parallel or series use?

Yes, leading manufacturers offer matched-pair or array configurations with tightly binned capacitance and ESR values to ensure balanced loading. Confirm whether sorting is performed at DC bias and across temperature ranges relevant to your application.

Do suppliers support small MOQs for testing?

Many suppliers accept MOQs as low as 1,000 units for initial trials. Some waive tooling fees for prototype runs if followed by volume orders. Expect unit pricing premiums of 15–25% for low-volume batches.

What customization options are available for capacitor networks?

Suppliers can customize terminal types, case sizes, capacitance values, and dielectric materials (e.g., X7R, NP0, tantalum). For integrated solutions, inquire about multi-capacitor modules or stacked configurations designed for high-density power circuits.