Car Key Machine Maker

1/28

1/28

1/14

1/14

1/14

1/14

1/24

1/24

1/21

1/21

1/7

1/7

About car key machine maker

Where to Find Car Key Machine Makers?

China remains the dominant hub for car key machine manufacturing, with key production clusters concentrated in Guangdong and Henan provinces. These regions host vertically integrated facilities that combine R&D, component sourcing, and final assembly under one ecosystem, enabling cost efficiencies and rapid scalability. Shenzhen-based suppliers leverage proximity to electronics supply chains, offering advanced models with digital controls and automation features, while Henan manufacturers focus on mechanical durability and high-volume output for locksmithing and automotive service markets.

The industrial clusters support agile production cycles due to localized access to CNC machining, motor systems, and precision tooling components. Suppliers typically operate dedicated production lines for vertical, horizontal, and fully automatic key duplicating machines, allowing customization across voltage (110V–220V), power ratings (180W standard), and material compatibility (brass, steel, nickel-plated blanks). Buyers benefit from shorter lead times—averaging 15–30 days for standard orders—and competitive pricing driven by economies of scale and mature supplier networks within 50km radii.

How to Choose Car Key Machine Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional criteria:

Technical Specifications & Compliance

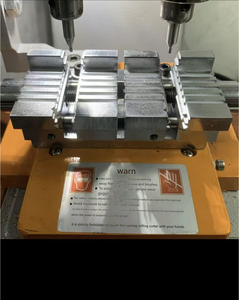

Verify that machines meet international safety and performance benchmarks. Look for CE marking as a baseline indicator of electrical and mechanical compliance, particularly for export to EU and North American markets. Confirm operational specifications including motor power (typically 180W), cutting accuracy (±0.05mm tolerance), and compatibility with common key profiles (e.g., 368A, DEFU-001, S60G2). Request test reports or video demonstrations validating machine calibration and blade longevity.

Production Capability Verification

Assess core manufacturing infrastructure through available data points:

- Ownership of in-house production lines (confirmed via "own production line" tags)

- Monthly output capacity inferred from minimum order quantities (MOQs) and reorder rates

- Customization capabilities: color, logo, packaging, and graphic labeling options

- Inclusion of R&D elements such as smart key programming or self-service kiosk integration

Cross-reference response times (≤1h to ≤5h) and on-time delivery rates (92–99%) as proxies for operational efficiency and supply chain reliability.

Transaction Security & Quality Assurance

Prioritize suppliers with verifiable transaction histories and documented quality control processes. Analyze online revenue indicators (ranging from US $10,000+ to over US $420,000+) as signals of market presence and order volume. Utilize secure payment mechanisms such as escrow services, especially for first-time engagements. Conduct pre-shipment inspections or request sample units to evaluate build quality, noise levels, and ease of use before full-scale procurement.

What Are the Best Car Key Machine Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Henan Locks Trading Co., Ltd. | Henan, CN | Vertical/horizontal duplicators, professional locksmith machines | Color, material, size, logo, packaging, label, graphic | 99% | ≤1h | 18% | US $210,000+ | $60–459 |

| Shenzhen Topbest Technology Co., Limited | Guangdong, CN | DEFU-series cutters, automatic vehicle key machines | Car door lock, motorcycle key, car key machine branding | 99% | ≤3h | 32% | US $420,000+ | $60–351 |

| Shenzhen Hua Shi Locksmith Technology Co. Ltd. | Guangdong, CN | Smart key systems, Xhorse Dolphin, KEYDIY KD-X2 | Limited customization; focused on branded diagnostics | 97% | ≤5h | <15% | US $90,000+ | $138–$6,999.99 |

| FOSHAN LHF TECHNOLOGY CO.,LTD | Guangdong, CN | DEFU 100E1, auto key makers, duplicators | Material, size, logo, packaging | 94% | ≤4h | 24% | US $20,000+ | $22–350 |

| Qingxin Tech (Guangzhou) Co., Ltd. | Guangdong, CN | Xhorse Condor, KEYDIY remotes, universal cutters | Remote control and button configuration | 92% | ≤3h | 17% | US $10,000+ | $10–$3,299 |

Performance Analysis

Shenzhen Topbest Technology leads in reorder rate (32%) and total online revenue (US $420,000+), indicating strong customer retention and market penetration, likely supported by competitive pricing and broad product range. Henan Locks Trading excels in responsiveness (≤1h) and delivery reliability (99%), making it suitable for time-sensitive procurement. Guangdong-based firms dominate innovation, offering high-end automated and smart key programming systems, albeit at higher price points ($1,500+ for smart models).

Suppliers like FOSHAN LHF TECHNOLOGY offer entry-level machines starting at $22, ideal for small workshops or distributors targeting budget segments. In contrast, Qingxin Tech provides niche, premium equipment such as the $3,299 Xhorse Condor XC-009, catering to professional locksmiths requiring precision and diagnostic integration. Reorder rates below 20% suggest room for service improvement among newer entrants, while consistent on-time delivery (>94%) across all five indicates reliable logistics execution.

FAQs

How to verify car key machine supplier reliability?

Cross-check claims of "own production line" with facility videos or third-party audit reports. Validate certifications (CE, ISO) through issuing bodies. Examine transaction metrics: prioritize suppliers with ≥97% on-time delivery, sub-4-hour response times, and verifiable customization experience.

What is the typical MOQ and lead time?

Minimum Order Quantities range from 1 piece for standard models to 50 sets for self-service kiosks. Lead times average 15–25 days post-payment confirmation, depending on order complexity and customization level. Air freight adds 7–10 days for international delivery.

Can suppliers customize car key machines?

Yes, most suppliers listed offer customization in color, material, size, logo imprinting, packaging, and graphical design. Advanced configurations may include brand-specific labeling or integration with existing workshop management systems. Confirm feasibility via direct inquiry and request mock-up samples before production.

Do manufacturers provide samples?

Sample availability varies. Some suppliers offer single-unit purchases at quoted prices (e.g., $60–70 for basic models), effectively serving as testable samples. Others require MOQ fulfillment even for trial runs. Expect partial reimbursement if the sample cost is credited toward a subsequent bulk order.

How to assess technical support and after-sales service?

Evaluate support readiness through response time consistency and communication clarity. Leading suppliers provide instructional videos, user manuals in English, and troubleshooting guides. For complex systems, confirm remote assistance or firmware update capabilities. Review reorder rates and customer feedback for indirect insights into long-term satisfaction.