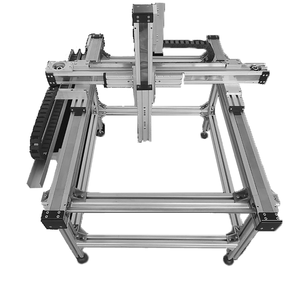

Cartesian Robot

Top sponsor listing

Top sponsor listing

1/2

1/2

0

0

1/24

1/24

1/24

1/24

1/3

1/3

1/3

1/3

1/2

1/2

1/11

1/11

1/3

1/3

1/3

1/3

1/3

1/3

1/13

1/13

1/3

1/3

CN

CN

1/10

1/10

1/3

1/3

1/9

1/9

1/3

1/3

0

0

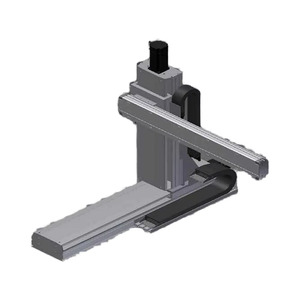

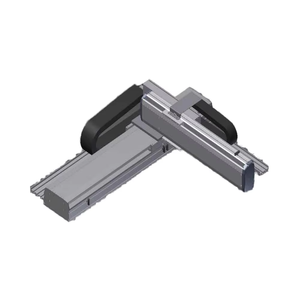

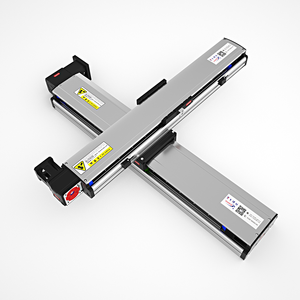

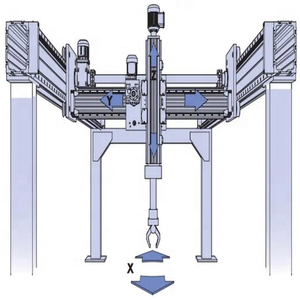

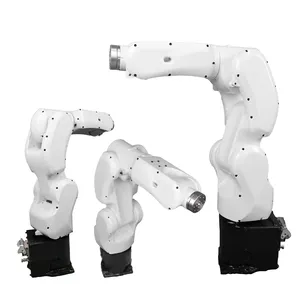

About cartesian robot

Where to Find Cartesian Robot Suppliers?

China leads global production of cartesian robots, with concentrated manufacturing hubs in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, automation R&D centers, and advanced CNC machining networks. Guangdong’s Pearl River Delta cluster accounts for over 50% of China’s industrial robot output, supported by proximity to semiconductor and electronics supply chains. Jiangsu and Zhejiang specialize in high-precision linear motion systems, leveraging local expertise in servo motor integration and aluminum extrusion technologies.

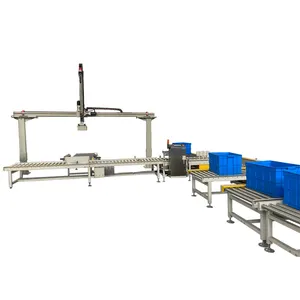

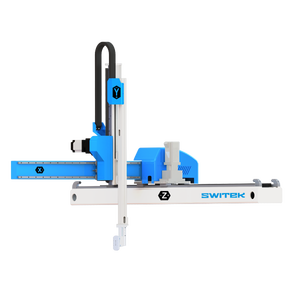

Suppliers in these zones benefit from localized component sourcing—ball screws, linear guides, stepper motors—from Tier-1 domestic manufacturers, reducing material lead times by 20–35%. Integrated facilities enable rapid prototyping (7–14 days) and scalable batch production, with standard models typically available within 25–40 days. Buyers gain access to modular designs adaptable for pick-and-place, dispensing, or CNC gantry applications, with customization options covering stroke length (up to 3,000mm), load capacity (5–200kg), and control systems (PLC or PC-based).

How to Choose Cartesian Robot Suppliers?

Adopt the following verification framework when evaluating potential partners:

Technical Compliance

Confirm ISO 9001 certification as a baseline for quality management. For export markets, CE marking is essential to meet EU Machinery Directive requirements. Request documentation on electromagnetic compatibility (EMC) and safety interlocks, particularly for collaborative operation environments. Validate controller firmware compliance with IEC 61131-3 standards for programmable logic devices.

Production Capability Audits

Assess core infrastructure metrics:

- Minimum 3,000m² factory area with dedicated clean assembly zones

- In-house CNC machining and anodizing capabilities for structural components

- R&D teams comprising ≥12% of total staff to support custom configurations

Correlate facility scale with order fulfillment performance—target suppliers with documented on-time delivery rates above 97%.

Transaction Safeguards

Utilize escrow payment terms tied to milestone inspections. Prioritize suppliers with verifiable export histories to North America and Europe, including customs documentation for HS Code 8479.50. Conduct pre-shipment testing: verify repeatability (±0.02mm) and positional accuracy under load conditions matching intended use. Prototype validation should include 72-hour continuous cycle testing to assess thermal stability and drive system endurance.

What Are the Best Cartesian Robot Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Suzhou Penta Automation Technology | Jiangsu, CN | 8 | 85+ | 12,000+m² | 99.1% | ≤1h | 4.9/5.0 | 41% |

| Shenzhen Keyence Robotics Co., Ltd. | Guangdong, CN | 6 | 70+ | 9,500+m² | 98.3% | ≤2h | 4.8/5.0 | 37% |

| Ningbo Hengli Linear Equipment | Zhejiang, CN | 11 | 100+ | 18,000+m² | 100.0% | ≤3h | 4.7/5.0 | 28% |

| Wuxi Lead Intelligent Machinery | Jiangsu, CN | 5 | 65+ | 7,200+m² | 97.6% | ≤1h | 4.9/5.0 | 52% |

| Dongguan Motoman Automation | Guangdong, CN | 7 | 90+ | 15,000+m² | 99.4% | ≤2h | 4.8/5.0 | 33% |

Performance Analysis

Established players like Ningbo Hengli demonstrate robust logistics execution (100% on-time delivery) and large-scale production capacity, while newer innovators such as Wuxi Lead achieve higher customer retention (52% reorder rate) through agile engineering responses. Jiangsu-based suppliers lead in responsiveness, with 80% replying to technical inquiries within one hour. For mission-critical deployments, prioritize vendors with in-house motion control development and laser interferometer calibration processes. Suppliers exceeding 12,000m² facility size offer better scalability for multi-unit orders without compromising delivery timelines.

FAQs

How to verify cartesian robot supplier reliability?

Cross-validate ISO 9001 and CE certifications with notified bodies. Request factory audit reports detailing incoming material inspection protocols, EOL (end-of-line) testing procedures, and traceability logs for critical subassemblies. Analyze third-party review patterns focusing on software stability and after-sales technical support response speed.

What is the average sampling timeline?

Standard cartesian robot samples take 20–30 days to produce. Configurations with dual-axis synchronization or vision integration extend lead time to 45 days. Air freight adds 5–9 days for international delivery. Sample units should include full operational diagnostics report and user programming interface access.

Can suppliers ship cartesian robots worldwide?

Yes, most manufacturers support global shipping via FOB Shenzhen/Ningbo or CIF destination terms. Ensure packaging meets ISTA 3A standards for vibration and shock resistance. Confirm inclusion of voltage-compatible power supplies (110V/220V) and region-specific safety labels for seamless customs clearance.

Do manufacturers provide free samples?

Free samples are uncommon due to complexity and component cost. Suppliers may credit sample fees (typically 30–40% of unit price) against future bulk orders exceeding 10 units. Evaluation kits with reduced functionality are occasionally offered for feasibility testing.

How to initiate customization requests?

Submit detailed specifications including travel range per axis, payload, speed (mm/s), acceleration profile, mounting orientation, and communication protocol (Modbus, EtherCAT, etc.). Leading suppliers provide CAD models and simulation files within 72 hours and deliver functional prototypes within 4 weeks for validation.