Cassava Starch Processing

1/11

1/11

1/6

1/6

1/12

1/12

1/9

1/9

1/12

1/12

1/13

1/13

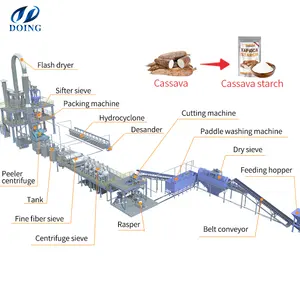

About cassava starch processing

Where to Find Cassava Starch Processing Equipment Suppliers?

China leads global production of cassava starch processing equipment, with key manufacturing clusters in Henan and Hunan provinces. Henan alone accounts for over 70% of China’s food processing machinery suppliers, supported by a dense network of component manufacturers and engineering talent. The region’s industrial ecosystem enables vertically integrated production—from stainless steel fabrication to motor assembly—reducing lead times and lowering costs by 20–30% compared to non-specialized regions. Hunan contributes niche innovation in compact, energy-efficient systems tailored for small-scale agricultural processors.

These hubs offer buyers access to scalable production capacity, with average supplier factory areas exceeding 5,000m² and monthly output capabilities ranging from 50 to 500 units per model. Proximity to raw material sources such as cold-rolled steel and food-grade polymers enhances cost efficiency. Buyers benefit from localized supply chains that support rapid prototyping, flexible batch sizing, and customization of critical components like crushers, sieves, and centrifugal separators. Standard lead times range from 15 to 30 days for stock models, with expedited builds available within 10 days for urgent orders.

How to Choose Cassava Starch Processing Equipment Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance and Design Capability

Verify adherence to international quality standards such as ISO 9001 and CE marking, particularly for electrical systems and mechanical safety. Assess design specifications including material compatibility (e.g., 304 stainless steel contact surfaces), moisture handling capacity, and throughput accuracy. Request performance data on extraction efficiency—top-tier machines achieve 85–92% starch recovery from fresh cassava roots.

Production Capacity and Infrastructure

Evaluate the following indicators of scalability and reliability:

- Minimum facility size of 3,000m² for consistent volume output

- In-house machining capabilities (CNC, welding, powder coating)

- Dedicated R&D or engineering team for custom configurations

Cross-reference declared output volumes with online revenue metrics and on-time delivery rates (target ≥98%) to validate operational stability.

Customization and Transaction Security

Confirm availability of OEM/ODM services including color coding, voltage adaptation (220V/380V), control panel localization, and branding. Prioritize suppliers offering third-party payment protection and documented dispute resolution processes. Pre-shipment inspection protocols should include load testing and dimensional verification. Sample units are typically available within 7–14 days for functional assessment.

What Are the Best Cassava Starch Processing Equipment Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Main Product Focus |

|---|---|---|---|---|---|---|---|

| Hunan Tingxiang Mechanical And Electrical Technology Co., Ltd. | Hunan, CN | US $110,000+ | 100% | ≤1h | 25% | Color, size, logo, packaging, label | Cassava starch processing equipment, cassava starch |

| Zhengzhou Pasen Machinery Co., Ltd. | Henan, CN | US $250,000+ | 100% | ≤4h | 16% | Color, material, size, logo, packaging, label, graphic | Cassava starch processing equipment, cassava starch |

| Henan Jinfuda Trading Co., Ltd. | Henan, CN | US $570,000+ | 98% | ≤3h | <15% | Color, material, size, logo, packaging, label, graphic | Cassava starch processing equipment, cassava starch |

| Henan Unio Machinery Co., Ltd. | Henan, CN | US $310,000+ | 99% | ≤2h | <15% | Color, material, size, logo, packaging, label, graphic | Cassava starch processing equipment, cassava starch |

| Henan Xinjusheng Trading Co., Ltd. | Henan, CN | US $130,000+ | 100% | ≤3h | <15% | Not specified | Vegetable cutters, food processing machinery, snack machines |

Performance Analysis

Henan-based suppliers dominate in scale and responsiveness, with Zhengzhou Pasen and Henan Jinfuda reporting higher annual revenues and comprehensive customization capabilities. Hunan Tingxiang stands out with a 25% reorder rate and sub-one-hour response time, indicating strong customer satisfaction despite lower overall revenue. All top-tier suppliers maintain on-time delivery rates above 98%, with three achieving perfect 100% fulfillment records. Customization depth varies: Pasen and Jinfuda offer material-level modifications, enabling integration into diverse production environments. While most suppliers serve broad food processing segments, specialization in cassava-specific machinery is evident in product naming, configuration, and pricing consistency.

FAQs

How to verify cassava starch processing equipment supplier reliability?

Validate certifications through independent registries and request factory audit reports or video walkthroughs. Analyze transaction history metrics such as on-time delivery rate, response speed, and reorder frequency. Review product documentation for material specifications, motor ratings, and safety compliance. Engage in direct technical discussions to assess engineering competence.

What is the typical minimum order quantity (MOQ) and pricing range?

MOQs vary by machine type and supplier, ranging from 1 set for high-end automated lines to 5–10 sets for modular units. Entry-level crushing machines start at $30–$75 per unit, while full extraction lines exceed $1,500. Bulk discounts are commonly offered beyond 10 units, with negotiated pricing available for container-load orders.

Can suppliers customize equipment for regional processing requirements?

Yes, leading suppliers provide extensive customization including voltage adjustment, corrosion-resistant coatings, feed hopper geometry, and automation level (manual, semi-auto, fully automatic). Some offer turnkey plant design support for integrated cassava starch facilities with capacities from 500kg/h to 1,500kg/h.

Do suppliers provide samples or trial units?

Sample availability depends on equipment complexity. Small-scale grinders and extractors can be shipped as samples within 7–10 days, often at partial cost coverage. Full production-line trials are conducted at supplier facilities upon request. Buyers are advised to conduct performance benchmarking before large-scale procurement.

What are the standard logistics and export terms?

Most suppliers offer FOB, CIF, and DAP shipping options with sea freight recommended for full-container loads due to cost efficiency. Air freight is viable for sample units or urgent spare parts. Packaging typically includes wooden crates for structural protection and moisture-resistant wrapping for coastal shipments.