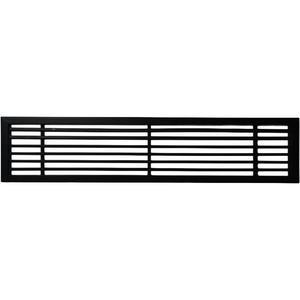

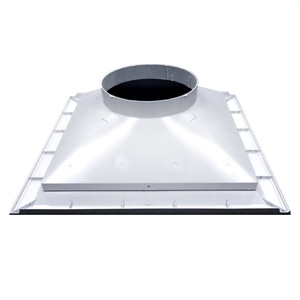

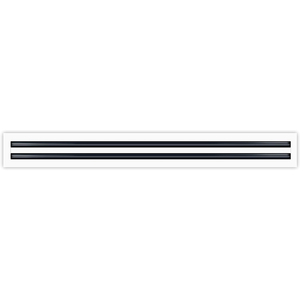

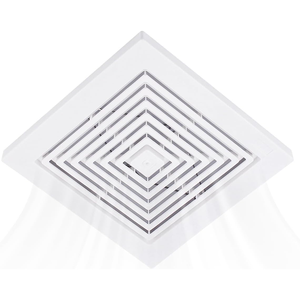

Ceiling Air Diffuser

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About ceiling air diffuser

Where to Find Ceiling Air Diffuser Suppliers?

China remains the central hub for ceiling air diffuser manufacturing, with key production clusters in Guangdong, Henan, and Fujian provinces. These regions host vertically integrated supply chains specializing in HVAC components, enabling efficient material sourcing and rapid prototyping. Foshan in Guangdong Province is particularly notable for its concentration of ventilation system manufacturers, leveraging proximity to aluminum and plastic extrusion facilities to reduce lead times by 15–20% compared to offshore alternatives.

The industrial ecosystem supports both mass production and low-volume customized orders, with suppliers equipped with CNC punching, powder coating lines, and anodizing capabilities. Many factories operate under ISO 9001 quality management frameworks, ensuring consistency in dimensional tolerances and airflow performance. Buyers benefit from localized access to raw materials—such as 6063-T5 aluminum, ABS, and PVC—reducing component costs by up to 30%. Standard lead times range from 15–30 days, depending on customization level and order volume.

How to Choose Ceiling Air Diffuser Suppliers?

Procurement decisions should be guided by technical capability, compliance verification, and operational reliability metrics:

Material & Engineering Specifications

Confirm supplier expertise in working with specified materials: aluminum (for corrosion resistance and durability), thermoplastics (ABS/PVC for lightweight applications), or composite finishes. Evaluate design flexibility for slot width (commonly 3–25mm), faceplate dimensions, and integration with fire dampers or sensor modules. Suppliers offering CAD support, 3D modeling, and airflow simulation data provide added engineering value.

Quality Assurance Protocols

Prioritize suppliers with documented quality control systems. While formal ISO certification is not universally listed, consistent on-time delivery rates above 97% and product conformity to international standards (e.g., ASTM E84 for flame spread index) are strong proxies for reliability. Request test reports for salt spray resistance (critical for coastal installations) and static pressure performance.

Production Capacity Verification

Assess scalability through facility indicators:

- Minimum factory area exceeding 3,000m² for sustained output

- In-house tooling and mold-making capabilities for custom profiles

- Anodizing or powder coating lines for surface finish control

Cross-reference online transaction volumes with reorder rates; suppliers with >15% repeat order rates demonstrate customer satisfaction and product consistency.

Customization & Logistics Readiness

Verify options for color matching (RAL/DIN standards), logo imprinting, end-cap designs, and packaging configurations. Confirm export experience, including proper labeling, moisture-resistant packaging, and compatibility with containerized shipping. Escrow-based payment terms mitigate risk during initial engagements.

What Are the Best Ceiling Air Diffuser Suppliers?

| Company Name | Main Materials | Customization Options | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Product Range |

|---|---|---|---|---|---|---|---|

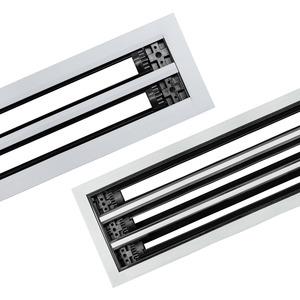

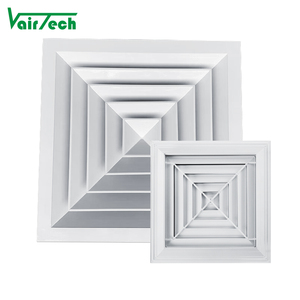

| Foshan Vairtech Ventilation Co., Ltd. | Aluminum, PVC, ABS | Color, size, slot width, finish, fire damper, sensor integration | 97% | ≤1h | 15% | US $1,900,000+ | Linear slot, square, round, flush-mount diffusers |

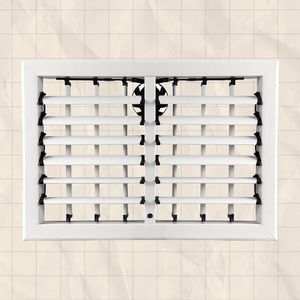

| Zhengzhou Yugongzhongcheng Energy Saving Technology Co., LTD | ABS, PVC | Color, thickness, logo, packaging, dimensions | 100% | ≤2h | <15% | US $40,000+ | Plastic louvers, adjustable vents, round ceiling models |

| Zhaoqing Grandaire Air Conditioning Co., Ltd. | Aluminum | Limited customization (removable core, panel style) | 66% | ≤4h | 100% | US $250,000+ | Round, square, flat-panel aluminum diffusers |

| Xiamen Green Foam Insulation Material Co., Ltd. | Aluminum | Slot count (2–4), finish, connection type | 100% | ≤1h | <15% | US $80,000+ | Linear grilles, spiral ducts, 4-way square diffusers |

Performance Analysis

Foshan Vairtech leads in engineering versatility and scale, offering extensive customization across materials and smart integrations, supported by high revenue volume and sub-hour response times. Zhengzhou Yugongzhongcheng and Xiamen Green Foam achieve perfect on-time delivery records, indicating robust production planning, though lower reorder rates suggest room for improvement in post-sale engagement. Zhaoqing Grandaire stands out with a 100% reorder rate, reflecting strong customer retention despite slower response cycles and moderate delivery performance. Aluminum-focused suppliers dominate premium segments, while plastic-based producers serve cost-sensitive residential and retrofit markets.

FAQs

What materials are commonly used in ceiling air diffusers?

Primary materials include 6063-T5 aluminum (for durability and corrosion resistance), ABS (impact-resistant thermoplastic), and PVC (low-cost, moisture-proof). Surface treatments include anodizing, powder coating, and paintable finishes for architectural integration.

What is the typical MOQ for ceiling air diffusers?

MOQ varies by material and complexity: 10–20 pieces for high-value aluminum models, 100+ pieces for plastic variants. Some suppliers offer single-piece sampling at premium rates for design validation.

How long does customization take?

Standard custom orders require 20–25 days, including tooling adjustments and finish application. Complex requests involving sensors, special alloys, or integrated dampers may extend lead times to 35 days.

Can suppliers provide technical drawings and samples?

Yes, most suppliers offer dimensioned CAD drawings, airflow diagrams, and physical samples upon request. Sample lead time averages 7–14 days, with express shipping options available.

Are ceiling air diffusers compliant with building codes?

Compliance depends on regional regulations. Suppliers should confirm adherence to local fire safety standards (e.g., UL 263/ASTM E84 for smoke development) and provide documentation for submittal. Fire-rated models with dampers are available for commercial applications.