Ceiling Track Lights

Top sponsor listing

Top sponsor listing

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/20

1/20

1/2

1/2

CN

CN

1/60

1/60

0

0

0

0

1/3

1/3

1/3

1/3

1/27

1/27

0

0

1/3

1/3

1/12

1/12

1/3

1/3

1/3

1/3

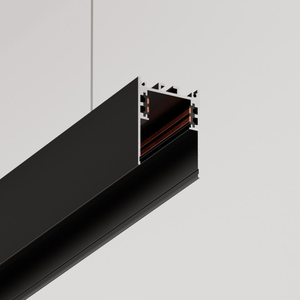

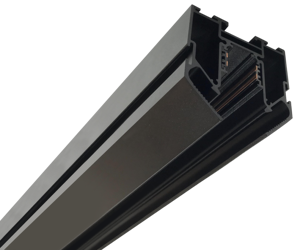

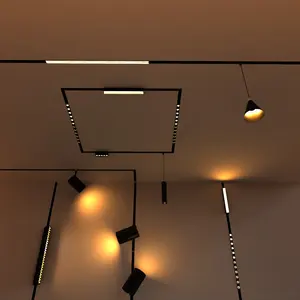

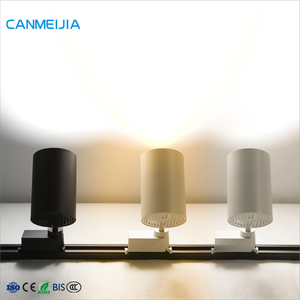

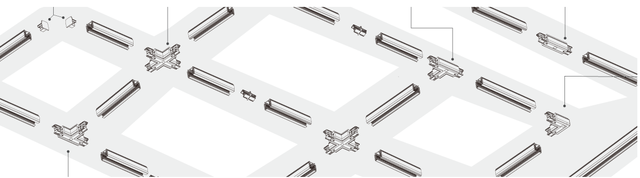

About ceiling track lights

Where to Find Ceiling Track Lights Suppliers?

China remains the central hub for ceiling track lights manufacturing, with key production clusters in Guangdong and Zhejiang provinces. These regions host vertically integrated supply chains encompassing die-casting, extrusion, LED module assembly, and surface treatment processes. Guangdong, particularly around Shenzhen and Dongguan, specializes in high-efficiency SMD LED integration and smart lighting systems, leveraging proximity to semiconductor and electronics suppliers. Zhejiang’s Yuyao and Ningbo zones focus on aluminum profile fabrication and powder coating, achieving 10–15% cost efficiencies in structural components due to localized raw material sourcing.

The industrial ecosystems support rapid prototyping and scalable production, with many facilities operating automated SMT lines capable of 500,000+ units per month. Component co-location reduces logistics overhead and enables lead times as short as 20–35 days for standard configurations. Buyers benefit from consolidated vendor networks where optical lenses, drivers, mounting hardware, and control modules are sourced within 30km, ensuring consistent quality alignment and responsive rework cycles. Bulk procurement advantages include 25–35% lower unit costs compared to EU- or US-based manufacturers and MOQs ranging from 50 to 500 units depending on customization level.

How to Choose Ceiling Track Lights Suppliers?

Implement structured evaluation criteria to mitigate quality and compliance risks:

Technical Compliance

Confirm adherence to IEC 60598-1 safety standards and EMC requirements (EN 55015, EN 61547). For markets requiring regulatory approval, verify valid CE, RoHS, and UKCA certifications. North American projects demand ETL or UL listing for damp or wet location ratings. Request photometric test reports (LM-79) and IP rating validation for recessed or high-humidity installations.

Production Capability Audits

Assess operational scale and technical autonomy:

- Minimum 3,000m² factory area with dedicated clean-room SMT zones

- In-house tooling and mold-making capacity for custom track profiles

- Integrated testing stations for electrical safety (hipot), thermal performance, and flicker index

Validate facility capabilities via video audits and request evidence of monthly output volume. Prioritize suppliers with driver aging chambers and integrating spheres for consistent lumen maintenance data.

Transaction Safeguards

Utilize secure payment structures such as LC at sight or escrow services tied to shipment milestones. Review supplier export history—prefer partners with documented shipments to Tier-1 distributors or commercial projects. Conduct pre-shipment inspections using third-party QA firms to verify color temperature consistency (±3SDCM), beam angle accuracy, and mechanical tolerance. Sample validation should include 72-hour burn-in tests and dimming compatibility checks across leading TRIAC, 0–10V, and DALI protocols.

What Are the Best Ceiling Track Lights Suppliers?

No supplier data available for analysis.

Performance Analysis

In absence of specific supplier metrics, procurement strategy should emphasize certification verification and process transparency. Prioritize manufacturers demonstrating full traceability from LED binning to final assembly. For architectural or retail applications requiring precise beam control, confirm access to Type II–V optics libraries and adjustable head mechanisms. Evaluate responsiveness through technical engagement—suppliers capable of providing IES files, layout simulations, and wiring schematics within 48 hours typically exhibit stronger engineering support infrastructure.

FAQs

How to verify ceiling track lights supplier reliability?

Cross-reference issued certificates with notified bodies. Request factory audit reports detailing QC checkpoints, solder reflow profiles, and driver burn-in procedures. Analyze customer references for project-specific installations, especially in commercial or healthcare environments where lighting performance is mission-critical.

What is the average sampling timeline?

Standard samples take 7–14 days for existing models. Custom designs involving new extrusions or PCB layouts require 20–30 days, including tooling setup. Air freight adds 5–9 days for international delivery.

Can suppliers ship ceiling track lights worldwide?

Yes, experienced exporters manage global logistics via FOB, CIF, or DDP terms. Confirm packaging specifications meet drop-test standards for long-haul transport. Ensure documentation includes circuit diagrams, warning labels in local language, and compliance marks accepted in destination markets.

Do manufacturers provide free samples?

Sample policies vary by order potential. Established suppliers may waive fees for qualified buyers committing to minimum annual volumes (e.g., 1,000+ units). Otherwise, expect charges covering 40–60% of sample cost, redeemable against first production run.

How to initiate customization requests?

Submit detailed specifications including track length (1m–4m standard), finish (anodized, white paint, brushed nickel), voltage (120V/220V/277V), and control type (phase-cut, 0–10V, wireless). Reputable partners provide CAD drawings, photometric data, and prototype units within 3–5 weeks for approval.