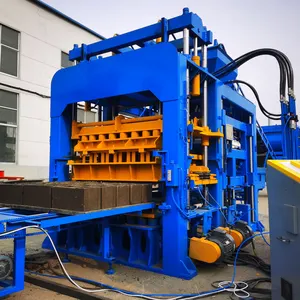

Cement Block Maker Machine Price

CN

CN

About cement block maker machine price

Where to Find Cement Block Maker Machine Suppliers?

China remains the dominant global hub for cement block making machine manufacturing, with key industrial clusters concentrated in Hebei, Shandong, and Qingdao regions. These provinces host vertically integrated supply chains that support rapid prototyping and large-scale production of hydraulic, semi-automatic, and fully automatic block molding systems. The proximity to raw material sources—such as steel and casting components—enables cost efficiencies, with localized production reducing unit costs by 18–25% compared to non-Asian manufacturers.

Suppliers in these zones benefit from mature construction machinery ecosystems, where specialized component vendors, automation engineers, and logistics networks operate within compact geographic radii. This integration allows standard lead times of 20–40 days for ready-to-ship models, while customized configurations typically require 45–60 days. Economies of scale are evident among high-volume producers, some reporting monthly outputs exceeding 100 units per facility. Buyers gain access to diverse machine types—from manual brick presses to high-capacity QT8-15 models—capable of producing interlocking pavers, hollow blocks, and solid concrete units.

How to Choose Cement Block Maker Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical capability, operational transparency, and transactional reliability:

Technical Specifications & Compliance

Verify adherence to international safety and performance standards such as CE, ISO 9001, and applicable electrical or mechanical certifications. Request documentation on core system components—including hydraulic pressure ratings (typically 16–25 MPa), mold compatibility, and power requirements (three-phase motors common). Confirm machine specifications align with local grid conditions and production targets (e.g., output capacity of 1,500–6,000 blocks per hour depending on model).

Production Capacity Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house engineering teams supporting customization (e.g., pallet size, block design, automation level)

- On-site CNC machining, welding, and assembly lines to ensure quality control

Cross-reference declared capabilities with on-time delivery rates; prioritize suppliers maintaining ≥97% fulfillment consistency.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services until post-delivery inspection is completed. Prioritize suppliers offering sample testing protocols and third-party inspection acceptance. Conduct video audits of production facilities to validate claims about machinery calibration, inventory management, and packaging procedures before finalizing orders.

What Are the Best Cement Block Maker Machine Suppliers?

| Company Name | Location | Online Revenue | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Hebei Zhongke Jiantong Machinery Equipment Co., Ltd. | Hebei, CN | US $80,000+ | Brick Making Machinery (293) | 100% | ≤4h | <15% | Limited | $289–6,940 |

| Shandong Canhua International Trade Co., Ltd. | Shandong, CN | US $170,000+ | Brick Making Machinery, Concrete Mixers | 100% | ≤2h | <15% | Extensive (material, color, automation) | $5,450–29,500 |

| Qingdao Darifeng Machinery Co., Ltd. | Qingdao, CN | US $500,000+ | Brick Making Machinery, Hydraulic Presses | 97% | ≤5h | 54% | High (design, noise reduction, molds) | $5,800–18,500 |

| Linyi Aiwei International Trade Co., Ltd. | Shandong, CN | US $30,000+ | Concrete Block Machines, Batching Systems | 100% | ≤1h | 16% | Moderate (conveyor, mold, phase options) | $2,189–25,000 |

| Gongyi Yayuan Trade Co., Ltd. | Henan, CN | US $1,000+ | Plastic Crushers, Brick Machines | 100% | ≤1h | - | Limited | $1,550–45,000 |

Performance Analysis

Qingdao Darifeng stands out with the highest reorder rate (54%), indicating strong customer satisfaction despite slightly longer response times. Its extensive customization portfolio supports complex production needs, including low-noise operation and multi-shape mold integration. Shandong Canhua offers broad configurability and competitive pricing across mid-to-high-end models, backed by fast response cycles (≤2h) and full automation options. Hebei Zhongke provides entry-level machines at aggressive price points ($289), suitable for small-scale operations but with limited technical scalability. Linyi Aiwei demonstrates responsiveness and reliability, though its product range skews toward higher-priced industrial units. Gongyi Yayuan lists ultra-low-cost manual models but lacks reorder data and has minimal specialization in brick-making equipment relative to other product lines.

FAQs

What is the typical MOQ for cement block making machines?

Most suppliers set a minimum order quantity (MOQ) of 1 set for standard models. Bulk discounts may apply for orders of 3 or more units, particularly for manual or semi-automatic variants.

How long does production and shipping take?

Lead time averages 20–30 days for in-stock machines and 45–60 days for custom-built systems. Sea freight transit adds 25–40 days depending on destination region. Air freight is rarely used due to size and weight constraints.

Can I request custom modifications?

Yes, many suppliers offer customization for mold dimensions, automation level, conveyor configuration, power source (electric/hydraulic), and branding (logo, color). Confirm feasibility via technical drawings and prototype validation prior to order placement.

Are samples available before bulk purchase?

Full-machine samples are generally not provided due to size and cost. However, suppliers may offer test videos, factory demonstrations, or component samples (e.g., produced blocks) to verify performance. Some waive sampling fees upon confirmation of future volume orders.

What payment terms are common in international transactions?

Standard terms include 30% advance payment via T/T, with balance due before shipment. Escrow services and Trade Assurance programs are recommended to mitigate risk. Letters of credit (L/C) are accepted by larger exporters for high-value contracts.