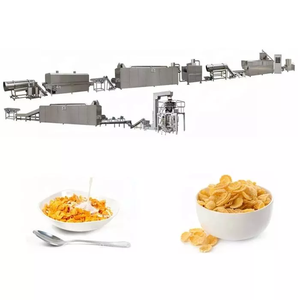

Cereal Processing Machines

CN

CN

CN

CN

About cereal processing machines

Where to Find Cereal Processing Machine Suppliers?

China remains the global epicenter for cereal processing machine manufacturing, with key production clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine raw material access, precision engineering, and streamlined logistics. Shandong, in particular, has emerged as a hub for high-capacity food processing lines, leveraging proximity to port infrastructure for efficient export distribution. The concentration of technical expertise and component suppliers within 50km radii enables rapid assembly and testing cycles, supporting both standard and customized machinery deployment.

Suppliers in these zones operate facilities ranging from 5,000 to over 24,000m², equipped with CNC machining centers, welding automation, and in-house R&D units focused on extrusion, puffing, and drying technologies. This integration reduces lead times to 30–60 days for full production lines and allows cost advantages of 20–35% compared to European or North American manufacturers. Buyers benefit from scalable solutions—from compact single-screw extruders for startups to fully automated breakfast cereal lines capable of 500–1,000 kg/h output.

How to Choose Cereal Processing Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international quality standards such as ISO 9001. For exports to regulated markets (EU, USA), confirm CE marking and compliance with food safety regulations including FDA and EU 1935/2004 on materials in contact with food. Request documentation for critical components—especially twin-screw extruders, drying ovens, and coating systems—and validate use of food-grade stainless steel (e.g., SUS304).

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Facility size exceeding 3,000m² indicating capacity for large-scale production

- In-house design and engineering teams specializing in grain extrusion and thermal processing

- Integration of PLC-based automation and HMI control systems in machine builds

Cross-reference claimed capabilities with verified on-time delivery performance (target ≥97%) and response times (≤3 hours) to assess operational reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party payment protection and post-delivery commissioning support. Analyze reorder rates as an indicator of customer satisfaction—rates above 30% suggest strong service performance. Insist on sample testing before bulk orders, particularly for product formulation compatibility (e.g., corn, oats, rice-based cereals).

What Are the Best Cereal Processing Machine Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shandong Fuyun Group Co., Ltd. | Shandong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100% | ≤3h | Not Rated | <15% |

| LINYANG Machinery COLTD | Shandong, CN | Data Unavailable | Data Unavailable | Data Unavailable | Not Reported | ≤1h | Not Rated | Not Reported |

| FENG LIAN DA MACHINERY CO LTD | Shandong, CN | Data Unavailable | Data Unavailable | Data Unavailable | Not Reported | ≤1h | Not Rated | Not Reported |

| Zhengzhou Qiongdan Machinery Co., Ltd. | Henan, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100% | ≤2h | Not Rated | <15% |

| Shandong Joyang Machinery Co., Ltd. | Shandong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100% | ≤1h | Not Rated | 66% |

Performance Analysis

Among analyzed suppliers, Shandong Joyang Machinery stands out with a 66% reorder rate—indicating high client retention—and sub-hour response times, suggesting robust customer engagement. While all listed companies report 100% on-time delivery where data is available, Joyang’s repeat business volume reflects superior post-sale support and system reliability. LINYANG and FENG LIAN DA emphasize rapid communication (≤1h response) and specialize in extrusion-based cereal lines, targeting mid-to-high-end market segments with equipment priced between $16,000 and $93,000 per set. In contrast, Shandong Fuyun and Zhengzhou Qiongdan offer entry-level automation at $499–$6,000, suitable for small producers or snack bar applications. Buyers seeking granola, puffed cereals, or fortified nutritional rice should prioritize suppliers with twin-screw extruder experience and customization options for texture, density, and flavor infusion.

FAQs

How to verify cereal processing machine supplier reliability?

Cross-check ISO or CE certifications with issuing bodies and request factory audit reports. Review transaction histories for consistent on-time delivery and analyze customer feedback for insights into after-sales service and machine durability. Video tours of production floors can confirm in-house manufacturing versus outsourcing.

What is the typical lead time for cereal processing machines?

Standard configurations require 30–45 days for production and testing. Customized lines with multi-stage processes (extrusion, toasting, coating) may take 50–70 days. Shipping via sea freight adds 15–30 days depending on destination.

Do suppliers offer customization for cereal types?

Yes, most suppliers support configuration for corn flakes, oat clusters, puffed rice, maize snacks, and nutritionally fortified cereals. Customization includes screw design, die molds, temperature profiles, and automation level. Some providers offer recipe development assistance for new product launches.

What are common MOQ and pricing structures?

Minimum order quantity is typically 1 set. Entry-level machines start at $499, while fully automated lines range from $16,000 to over $90,000. Pricing reflects automation grade, output capacity, and material specifications (e.g., stainless steel vs. carbon steel frames).

Can suppliers assist with installation and training?

Reputable manufacturers provide remote commissioning support and instructional documentation. Some offer on-site technician dispatch (at buyer’s expense) for initial setup and operator training, especially for complex extrusion systems.