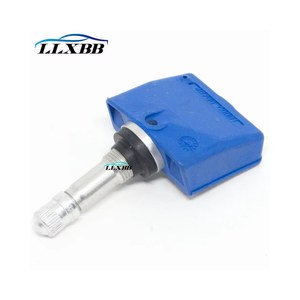

Change Tpms

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

About change tpms

Where to Find TPMS Sensor Suppliers?

China remains the central hub for TPMS (Tire Pressure Monitoring System) sensor manufacturing, with concentrated production clusters in Zhejiang, Guangdong, and Jiangsu provinces. These regions host over 70% of Asia’s automotive electronics suppliers, supported by mature PCB fabrication networks, SMT assembly lines, and proximity to Tier-1 automotive component distributors. Ningbo and Shenzhen specialize in high-volume OEM/ODM production, leveraging automated testing systems and low-cost semiconductor sourcing to achieve 25–35% lower unit costs compared to EU or North American manufacturers.

The industrial ecosystem enables rapid prototyping and scalable output, with many facilities operating ISO/TS 16949-aligned quality management systems. Integrated supply chains allow for streamlined procurement of critical materials such as aluminum alloy valve stems, rubber seals, and MEMS pressure transducers. Buyers benefit from lead times averaging 20–35 days for batch orders, modular design flexibility, and access to dual-frequency (315 MHz and 433 MHz) compatibility across global vehicle platforms.

How to Choose TPMS Sensor Suppliers?

Implement rigorous evaluation criteria to ensure technical reliability and supply chain consistency:

Quality & Compliance Verification

Confirm adherence to ISO 9001 and IATF 16949 standards as baseline indicators of process control. For export to regulated markets, validate CE, FCC, and RoHS certifications with official test reports. Request full documentation on EMI shielding performance, battery longevity (typically 5–7 years), and operating temperature range (-40°C to +125°C).

Manufacturing Capability Assessment

Evaluate key operational metrics:

- Minimum monthly output capacity of 100,000 units for volume stability

- In-house capabilities including SMT mounting, laser welding, and RF calibration

- Automated functional testing (pressure accuracy ±1 psi, transmission range verification)

Cross-reference factory size (recommended ≥3,000m²) with order fulfillment history to assess scalability.

Procurement Risk Mitigation

Utilize secure payment structures such as letter of credit or third-party escrow until product validation is complete. Prioritize suppliers offering sample testing under real-world conditions—verify signal interference resistance, seal integrity under vibration stress, and compatibility with major TPMS scan tools. Analyze after-sales support responsiveness and firmware update availability for programmable sensors.

What Are the Best TPMS Sensor Suppliers?

No supplier data available for comparative analysis.

Performance Analysis

In absence of specific supplier profiles, buyers should focus on regional strengths: Zhejiang-based manufacturers typically offer superior automation and traceability systems, while Guangdong suppliers excel in fast turnaround and multi-protocol programming. Emphasis should be placed on suppliers demonstrating compliance with OE specifications (e.g., matching OE part numbers for GM, Ford, Toyota, BMW). Video audits of SMT lines and QC checkpoints are recommended to verify claimed capabilities prior to order placement.

FAQs

How to verify TPMS sensor supplier reliability?

Audit certification validity through accredited bodies. Request batch-specific test logs covering pressure calibration, battery voltage screening, and RF output consistency. Review customer feedback related to field failure rates and reprogramming success across multiple vehicle makes.

What is the average sampling timeline?

Standard samples take 7–14 days to produce. Custom configurations requiring unique housing designs or frequency tuning may require 20–28 days. Air shipping adds 5–8 days for international delivery.

Can suppliers ship TPMS sensors worldwide?

Yes, experienced exporters manage global logistics via air or sea freight under EXW, FOB, or DDP terms. Confirm compliance with destination regulations, particularly FCC Part 15 for U.S. imports and E-Mark certification for European Union entry.

Do manufacturers provide free samples?

Sample policies vary by order volume. Many suppliers waive fees for qualified buyers committing to minimum 5,000-unit initial orders. Otherwise, expect to pay full production cost plus shipping for evaluation units.

How to initiate customization requests?

Submit detailed requirements including vehicle compatibility list, desired protocol (EEPROM type), casing material (brass, aluminum, or composite), and branding options (laser engraving, color coding). Reputable partners will return engineering drawings within 48 hours and deliver prototypes within four weeks.