China Custom Cnc Parts Factory

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/29

1/29

1/3

1/3

1/24

1/24

CN

CN

1/18

1/18

1/17

1/17

0

0

1/3

1/3

1/11

1/11

1/3

1/3

1/1

1/1

1/24

1/24

1/3

1/3

0

0

1/3

1/3

1/17

1/17

1/3

1/3

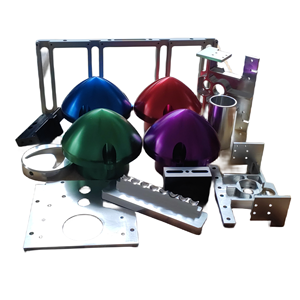

About china custom cnc parts factory

Where to Find Custom CNC Parts Suppliers in China?

China remains the global epicenter for precision CNC machining, with concentrated manufacturing hubs in Guangdong, Fujian, and Jiangsu provinces enabling rapid production of custom components. Shenzhen and Dongguan in Guangdong province host over 70% of high-precision CNC service providers, supported by mature ecosystems integrating material sourcing, multi-axis machining, and surface treatment capabilities. Xiamen in Fujian has emerged as a specialized center for small-batch, high-complexity parts, particularly for automotive and industrial equipment sectors.

These clusters benefit from vertically integrated supply chains—facilitating tight tolerances (±0.005mm) across aluminum, stainless steel, titanium, and alloy materials. Buyers access scalable production models: low-volume prototyping (1–100 units) with lead times of 7–14 days, and medium-volume runs (1,000+ units) within 20–30 days. Cost advantages range from 30–50% compared to domestic Western suppliers, driven by localized tooling, automation, and energy-efficient 5-axis CNC infrastructure.

How to Choose a Reliable Custom CNC Parts Supplier?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

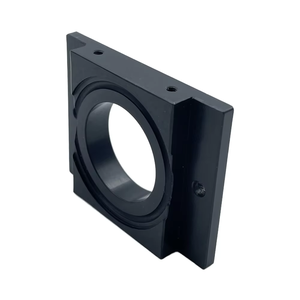

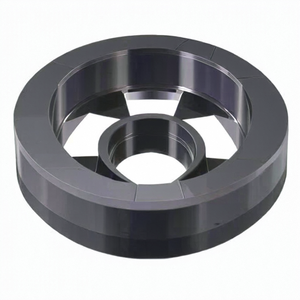

Technical & Production Capabilities

Verify access to multi-axis CNC milling, turning, grinding, and EDM processes. Suppliers should maintain in-house capabilities for secondary operations including anodizing, plating, laser engraving, and heat treatment. Priority should be given to manufacturers operating dedicated R&D or engineering teams capable of DFM (Design for Manufacturing) feedback. Facilities exceeding 3,000m² with documented monthly output capacity ensure scalability.

Quality Assurance Systems

Confirm adherence to ISO 9001 standards as a baseline. For regulated industries (medical, aerospace, automotive), request evidence of IATF 16949, AS9100, or RoHS compliance. Review inspection protocols: use of CMMs (Coordinate Measuring Machines), optical comparators, and first-article inspection (FAI) reports are indicators of robust quality control. On-time delivery rates above 95% and reorder rates exceeding 20% reflect consistent performance.

Customization & Transaction Security

Assess flexibility in material selection, finishing options, and OEM/ODM support. Leading suppliers offer full traceability, batch tracking, and packaging customization. Utilize secure payment mechanisms such as escrow services and insist on pre-shipment inspections. Analyze response times (ideally ≤2 hours) and language proficiency to ensure communication efficiency.

What Are the Top Custom CNC Parts Manufacturers in China?

| Company Name | Location | Main Services | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Xiamen RCH Import & Export Co., Ltd. | Fujian, CN | Machining, Casting | $30,000+ | 100% | ≤2h | 25% | 1 piece/set | $5–$1,580 |

| Shenzhen Rapid Manufacturing Co., Ltd. | Guangdong, CN | Machining, Sheet Metal | Not disclosed | 100% | ≤3h | Not available | 1–10 units | $0.50–$1.20 |

| Shenzhen Chengyue Intelligent Manufacturing Equipment Co., Ltd. | Guangdong, CN | Sheet Metal, Machining | $800+ | 66% | ≤2h | <15% | 1 piece | $0.01–$3.00 |

| Dongguan Zhonglijin Metal Products Co., Ltd. | Guangdong, CN | Casting, Machining, Sheet Metal | $40,000+ | 100% | ≤8h | 20% | 10 pieces | $0.25–$5.50 |

| Shenzhen Smart Mold Technology Limited | Guangdong, CN | Custom Machining, Prototyping | $900,000+ | 96% | ≤2h | 25% | 1 piece | $0.05–$5.15 |

Performance Analysis

Xiamen RCH and Shenzhen Rapid Manufacturing demonstrate strong reliability with 100% on-time delivery and responsive communication, suitable for time-sensitive prototyping and low-volume production. Shenzhen Smart Mold leads in transaction volume ($900K+ online revenue), indicating high market trust and repeat business, despite slightly lower delivery consistency (96%). Dongguan Zhonglijin offers broad process integration—casting, machining, and sheet metal—ideal for complex assemblies. In contrast, Shenzhen Chengyue, while offering ultra-low pricing from $0.01/unit, shows suboptimal delivery performance (66%), suggesting potential scalability or quality control limitations. Buyers requiring strict compliance should prioritize suppliers with verified revenue, high reorder rates, and documented quality systems.

FAQs

What is the typical MOQ for custom CNC parts in China?

Minimum order quantities vary: prototype orders often start at 1 piece, while cost-efficient production typically requires 10–100 units. High-volume runs (1,000+) achieve optimal per-unit pricing. Some suppliers waive MOQs for initial samples under buyer-funded terms.

How long does it take to receive custom CNC-machined parts?

Lead times average 7–14 days for prototypes and 15–30 days for production batches, depending on complexity, finishing requirements, and order volume. Express services may reduce turnaround to 5 days at a premium.

Can Chinese CNC factories handle tight-tolerance, high-precision components?

Yes, leading facilities utilize 5-axis CNC machines and CMM-based inspection to achieve tolerances as tight as ±0.005mm. Precision depends on machine calibration, operator skill, and quality management systems—verify capabilities through sample testing and facility documentation.

Do suppliers provide material certifications and inspection reports?

Reputable manufacturers supply mill test certificates (MTCs) for raw materials and first-article inspection reports upon request. Third-party inspection services (e.g., SGS, TÜV) can be arranged for high-value or regulated applications.

What file formats are accepted for CNC part designs?

Standard formats include STEP (.stp), IGES (.igs), SolidWorks (.sldprt), and DWG/DXF for 2D drawings. Suppliers typically require detailed technical specifications, including material grade, tolerances, surface finish, and critical dimensions.