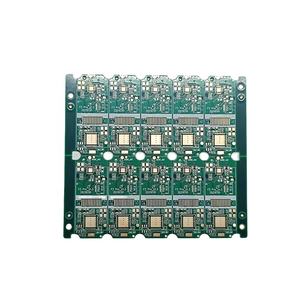

Circuit Board Components

Top sponsor listing

Top sponsor listing

About circuit board components

Where to Find Circuit Board Components Suppliers?

China remains the global epicenter for circuit board components manufacturing, with Shenzhen and Hong Kong serving as primary hubs due to their dense ecosystems of electronics OEMs, component distributors, and rapid prototyping facilities. These regions host vertically integrated supply chains that streamline material sourcing—from FR-4 substrates to surface-mount devices (SMDs)—enabling efficient production cycles for both standard and custom PCB assemblies.

The industrial clusters offer scalable solutions for low-volume prototypes and high-volume orders alike. Suppliers leverage automated SMT lines, in-house testing labs, and direct access to IC foundries and passive component stockists, reducing lead times by 20–35% compared to non-specialized manufacturers. Buyers benefit from localized logistics networks, allowing consolidated shipments and faster response to design revisions. Average production lead times range from 7–15 days for sample batches and 18–25 days for full-scale orders, depending on complexity and customization requirements.

How to Choose Circuit Board Components Suppliers?

Selecting reliable partners requires a structured evaluation of technical capability, quality assurance, and transaction reliability:

Technical & Production Capabilities

Verify suppliers have in-house capabilities across the full PCB lifecycle: design validation (Gerber file review), fabrication (multilayer, rigid, flexible, ceramic, or aluminum PCBs), component sourcing, SMT/DIP assembly, and functional testing. Prioritize suppliers offering one-stop PCBA services with demonstrated expertise in mixed-technology boards.

Evaluate infrastructure indicators:

- Minimum monthly output capacity exceeding 50,000 units for volume scalability

- In-house engineering support for design-for-manufacturability (DFM) analysis

- Support for advanced packaging, impedance control, and fine-pitch components

Cross-reference product listings with on-time delivery performance (target ≥94%) to assess operational stability.

Quality Assurance Standards

Confirm adherence to IPC-A-610 Class 2 or higher acceptance criteria for electronic assemblies. While formal ISO 9001 certification is not explicitly stated in all cases, consistent on-time delivery rates above 94% and documented rework procedures indicate robust internal quality systems. For export-bound electronics, ensure compliance with RoHS and REACH directives, particularly when supplying into EU or North American markets.

Customization & Transaction Reliability

Assess flexibility in size, color, layer count, material selection (e.g., flexible polyimide, aluminum-backed), and branding options such as silkscreen logos or custom packaging labels. Use response time (≤6 hours preferred) and reorder rate as proxies for customer satisfaction. Favor suppliers with transparent pricing structures, clear MOQ terms, and secure payment mechanisms such as escrow or milestone-based disbursements.

What Are the Best Circuit Board Components Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Key Capabilities |

|---|---|---|---|---|---|---|---|

| Kinglisheng(Shenzhen) Electronic & Technology Co., Limited | Shenzhen, CN | PCBA (411), Multilayer PCB (36), Ceramic PCB (9) | 92% | ≤2h | 46% | US $360,000+ | High-volume PCBA, multilayer & specialized substrate fabrication, full component sourcing, Gerber-based design support |

| Shenzhen Blue Bird Electronic Technology Co., Ltd. | Shenzhen, CN | PCBA (72), Microcontrollers (7), Transistors (3) | 100% | ≤6h | - | US $30+ | End-to-end PCBA, 14-year manufacturing experience, prototype-to-production scaling, small-batch customization |

| Pinsheng Electronics (HK) Co., Limited | Hong Kong, CN | PCBA (82), FPC (18), Heavy Copper PCB (13) | 94% | ≤6h | 40% | US $150,000+ | OEM/ODM services, flexible and heavy copper PCBs, stage lighting applications, batch traceability |

| Shenzhen Sinmicro Technology Ltd. | Shenzhen, CN | PCBA, Rigid/Flexible Design, Cloning Services | 96% | ≤3h | 22% | US $70,000+ | Low-MOQ assembly, design cloning, fast turnaround, multi-layer rigid-flex integration |

| PT TOMING MESIN INDONESIA | Indonesia | Waste Treatment Machinery (609), Scrap Shredders (107) | - | ≤2h | - | - | Electronic components dismantling machines—not a direct PCB component manufacturer; niche in recycling equipment |

Performance Analysis

Kinglisheng leads in scale and product diversity, with over 400 PCBA listings and strong reorder metrics, indicating consistent buyer retention. Shenzhen Blue Bird stands out for perfect on-time delivery despite lower online revenue, suggesting reliability for smaller or pilot orders. Pinsheng Electronics offers balanced performance with specialization in FPC and heavy copper PCBs—ideal for industrial and high-power applications. Sinmicro provides agile, low-MOQ solutions with responsive communication, suitable for startups and R&D projects. Notably, PT TOMING MESIN INDONESIA focuses on recycling machinery rather than component production, highlighting the importance of vetting supplier core competencies before engagement.

FAQs

How to verify circuit board components supplier reliability?

Cross-check delivery performance, response times, and listed product categories to confirm specialization in PCB/PCBA manufacturing. Request process documentation such as DFM reports, solder paste inspection (SPI) data, and AOI/X-ray test results. Evaluate technical responsiveness during inquiry stages as an indicator of post-order support quality.

What are typical MOQ and pricing structures?

MOQs vary widely: some suppliers offer single-piece prototypes starting at $0.20/unit, while others require minimum batches of 3–100 units. Pricing depends on layer count, surface finish, component density, and whether bare boards or full assemblies are ordered. High-volume orders (>1,000 pcs) typically achieve 30–50% cost reduction through economies of scale.

Can suppliers handle full turnkey assembly?

Yes, leading suppliers offer turnkey PCBA services including component procurement, BOM optimization, counterfeit part avoidance, and end-of-line functional testing. Confirm if they maintain authorized distributor partnerships or use independent sourcing channels, which affects component authenticity and warranty coverage.

Do suppliers support design cloning or reverse engineering?

Several suppliers, including Sinmicro and Kinglisheng, explicitly list PCB cloning and graphic/logo replication as services. Provide physical samples or scanned schematics for duplication, ensuring intellectual property rights are observed in target markets.

What logistics and export options are available?

Most suppliers ship globally via express carriers (DHL, FedEx) for samples and air freight for bulk orders. Sea freight is viable for container-sized consignments. Confirm Incoterms (FOB, CIF), customs documentation support, and compliance with destination regulations for electronic hardware.