Circular Formwork Columns Factories

CN

CN

CN

CN

About circular formwork columns factories

Where to Find Circular Formwork Columns Suppliers?

China remains the central hub for circular formwork columns manufacturing, with key production clusters concentrated in Henan, Shandong, and Jiangsu provinces. These regions host vertically integrated factories specializing in reusable concrete formwork systems, leveraging localized supply chains for steel, plywood, and engineered plastics. Henan’s Zhengzhou and Shandong’s Jinan are particularly notable for their high concentration of custom manufacturers equipped with dedicated production lines for modular column formwork.

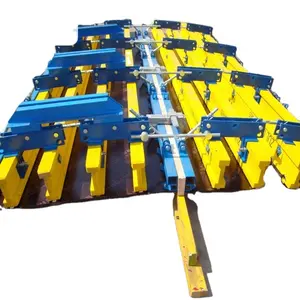

The industrial ecosystem supports both standard and engineered-to-order solutions, with many suppliers operating end-to-end facilities that include CNC cutting, bending, welding, and surface treatment units. This integration enables rapid prototyping and scalable output—typical lead times range from 15 to 30 days for bulk orders. Buyers benefit from cost efficiencies driven by domestic material sourcing and streamlined logistics, with average production costs 20–35% lower than equivalent Western suppliers. Most factories cater to international export markets, offering compliance-ready documentation and containerized packaging for global shipments.

How to Choose Circular Formwork Columns Suppliers?

Effective supplier selection requires a structured evaluation of technical capability, quality assurance, and transaction reliability:

Production Infrastructure Assessment

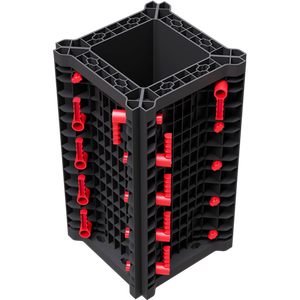

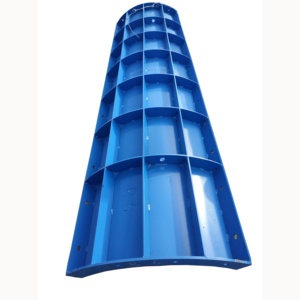

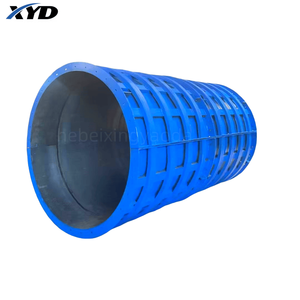

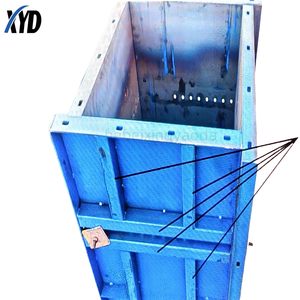

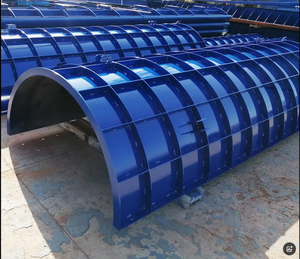

Prioritize suppliers with confirmed in-house manufacturing capabilities. Key indicators include ownership of dedicated molding or steel fabrication lines, capacity for diameter customization (typically ranging from 300mm to 3000mm), and ability to produce adjustable or non-adjustable configurations. Verify facility scale through available metrics such as monthly output volume or factory area, where leading producers report capacities exceeding 300 square meters per order.

Quality and Compliance Verification

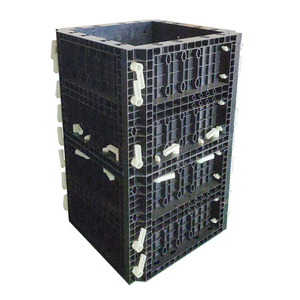

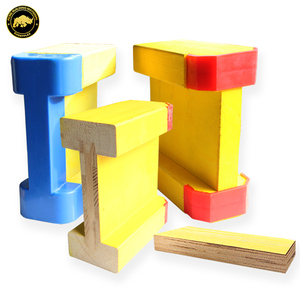

While formal certifications (e.g., ISO 9001) are not universally listed, consistent on-time delivery rates (target ≥97%) and documented response times (ideally ≤2 hours) serve as operational proxies for reliability. Evaluate whether suppliers provide technical drawings, material specifications, and load-bearing performance data. For plastic-based systems, confirm resin type (PP, PVC, ABS) and structural integrity under repeated use. Steel and plywood variants should specify thickness, bracing design, and galvanization level to ensure durability across multiple pours.

Customization and Transaction Safeguards

Assess customization scope—including diameter, height, interlocking mechanisms, surface finish, and branding options—through direct inquiry and sample validation. Require clear terms on minimum order quantity (MOQ), which varies significantly: plastic molds may require as little as 1–2 pieces, while steel or large-format plywood systems often mandate 100+ pieces or 200+ square meters. Utilize secure payment methods with milestone verification, especially for first-time engagements. Request product layout plans, assembly diagrams, and waterproofing test results prior to full-scale procurement.

What Are the Best Circular Formwork Columns Suppliers?

| Company Name | Location | Verified Type | Main Materials | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|---|

| Zhengzhou Songmao Building Materials Co., Ltd. | Henan, CN | Custom Manufacturer | Plywood, Plastic, Steel | $5.70–14.00 | 1–2 pieces | 100% | ≤2h | 20% | US $1.4M+ |

| SHANDONG ZEEMO CONSTRUCTION TECHNOLOGY CO LTD | Shandong, CN | Custom Manufacturer | Wood, Steel, Plywood | $9.00–15.90 | 100m–300m² | 100% | ≤3h | <15% | US $120K+ |

| Yancheng Lianggong Formwork Co.,ltd. | Jiangsu, CN | Custom Manufacturer | Plastic, Steel | $19.00–$1,200.00 | 100 pcs / 2 tons | 100% | ≤2h | 50% | US $920K+ |

| Work-Sun (beijing) International Trade Co., Ltd. | Beijing, CN | Custom Manufacturer | PP, PVC, ABS Plastic | $5.00–70.00 | 1–200 m² | 100% | ≤1h | 16% | US $2K+ |

| Shanxi Sufeng New Material Technology Co., Ltd. | Shanxi, CN | Multispecialty Supplier | PVC, Plastic | $1.50–40.00 | 1 meter / 50 pcs | 100% | ≤2h | <15% | US $10K+ |

Performance Analysis

Zhengzhou Songmao stands out for low MOQ flexibility and diverse material offerings, making it suitable for small-scale or prototype projects. Yancheng Lianggong demonstrates strong customer retention (50% reorder rate) and premium engineering capacity, particularly in heavy-duty steel formwork requiring ton-level orders. SHANDONG ZEEMO and Shanxi Sufeng focus on standardized plastic systems with competitive pricing, though lower online revenue suggests niche or regional market positioning. Work-Sun offers the fastest response time (≤1 hour), advantageous for urgent sourcing cycles. All top-tier suppliers maintain 100% on-time delivery records, indicating robust production planning and export coordination.

FAQs

What materials are commonly used in circular formwork columns?

The primary materials include laminated plywood, galvanized steel, and engineered thermoplastics (PP, PVC, ABS). Plywood is cost-effective for limited reuse, steel offers high load capacity for tall columns, and plastic provides lightweight, corrosion-resistant solutions ideal for repetitive casting.

What is the typical lead time for circular formwork orders?

Standard orders typically ship within 15–30 days after confirmation. Custom designs involving unique diameters, heights, or reinforcement may extend lead times to 35–45 days, depending on complexity and tooling requirements.

Can suppliers provide technical drawings and assembly instructions?

Yes, most verified manufacturers offer detailed product layouts, dimension schematics, and installation guides upon request. High-capability suppliers also provide CAD files or 3D models for integration into construction planning software.

Do suppliers support OEM or private labeling?

Extensive customization options are available, including logo printing, color coding, and tailored packaging. Suppliers such as Zhengzhou Songmao and Yancheng Lianggong explicitly list OEM services for plastic and steel formwork systems.

How are circular formwork columns packaged for export?

Products are typically palletized and shrink-wrapped for moisture protection. Flat-packed configurations optimize container space, with loading plans provided for 20ft or 40ft containers. Steel and plywood units may be bundled with protective corner guards and desiccants for long-haul shipments.