Cloth Pattern Maker

CN

CN

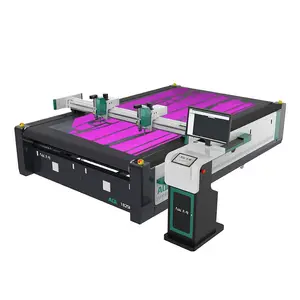

About cloth pattern maker

Where to Find Cloth Pattern Maker Suppliers?

China remains the global epicenter for cloth pattern maker manufacturing, with key industrial hubs in Henan, Shandong, and Hubei provinces driving innovation and scale. Zhengzhou (Henan) hosts compact machinery producers specializing in manual and semi-automated fabric swatch cutters, leveraging regional logistics networks for rapid dispatch. Shandong’s Jinan and Qingdao clusters focus on high-end CNC-driven digital cutting systems, supported by integrated metalworking and electronics supply chains that reduce component lead times by 20–25%.

These concentrated ecosystems enable vertical integration—from sheet metal fabrication to embedded software calibration—allowing suppliers to deliver standardized units within 15–30 days. Buyers benefit from proximity to ancillary service providers, including laser part marking, conveyor integration, and IoT-enabled monitoring module assembly, all within a 50-kilometer radius. The region supports flexible production runs, with MOQs as low as one set for entry-level models and scalable output for automated flatbed plotters capable of processing multi-layer textiles up to 6mm thickness.

How to Choose Cloth Pattern Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Equipment Scope

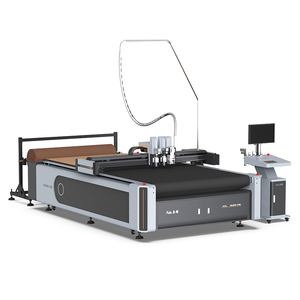

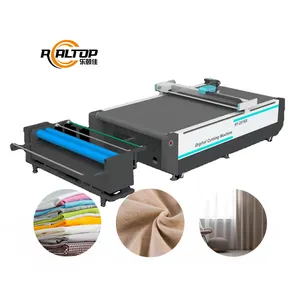

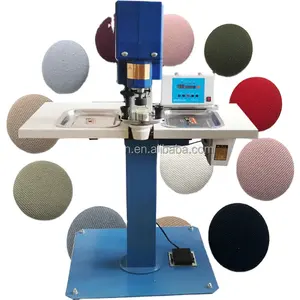

Confirm alignment between machine specifications and intended application. Entry-level manual swatch cutters (priced from $199) suit small studios, while industrial CNC fabric cutters ($10,000–$17,000) serve mass apparel producers requiring precision layer stacking and automatic feeding. Verify compatibility with target materials—cotton, polyester, fleece, PU leather—and assess blade or ultrasonic roller durability under continuous operation. CE marking is critical for European market compliance, particularly for electrical safety and EMC standards.

Production Capability Verification

Assess supplier infrastructure through measurable indicators:

- Facility size exceeding 3,000m² for sustained volume output

- In-house R&D capacity evidenced by digitizer integration, software interface development, or multi-material cutting heads

- On-site testing protocols for motion control accuracy (±0.1mm tolerance) and thermal management in ultrasonic embossing systems

Cross-reference online revenue metrics (e.g., US $300,000+) and reorder rates (>40%) as proxies for market validation and after-sales reliability.

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services to align payment release with equipment performance verification. Prioritize suppliers offering sample units or video demonstrations of live cutting operations. Analyze response time (<3 hours ideal) and on-time delivery records (≥94%) to gauge operational responsiveness. For customized configurations, confirm support for design uploads, graphic instruction sets, and labeling options prior to order confirmation.

What Are the Best Cloth Pattern Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Dream Machinery Co., Ltd. | Henan, CN | Manual cutters, zigzag textile cutters, sewing machines | US $20,000+ | 100% | ≤3h | 40% | $199–$1,659 | Limited |

| Shandong Yuchen Cnc Co., Ltd. | Shandong, CN | Automatic CNC cutting systems, digital garment pattern makers | US $300,000+ | 94% | ≤1h | 33% | $8,000–$15,190 | Full: material, size, feeding, packaging, logo |

| Wuhan GEMEI Joint Technology Co., Ltd | Hubei, CN | CNC garment machines, digitizers, sewing templates | US $10,000+ | 100% | ≤2h | <15% | $720–$4,690 | Moderate: includes multi-layer PVC cutting |

| Jinan Aol CNC Equipment Co., Ltd. | Shandong, CN | Digital oscillating cutters, flatbed apparel pattern systems | US $1,400,000+ | 92% | ≤2h | 43% | $10,000–$19,500 | Extensive: shape, design upload, precision tuning |

| Jinan Top Cnc Machines Co., Ltd. | Shandong, CN | Programmable sewing machines, die cutters, curtain fabric systems | US $40,000+ | 83% | ≤5h | 75% | $4,447–$7,980 | Standard: color, material, logo, packaging |

Performance Analysis

Jinan Aol CNC leads in high-value system deployment, commanding premium pricing supported by robust customization and a $1.4M+ online sales volume. Shandong Yuchen stands out for ultra-responsive communication (≤1h) and comprehensive post-purchase configuration support. While Jinan Top CNC reports the highest reorder rate (75%), its lower on-time delivery rate (83%) suggests potential fulfillment volatility. Zhengzhou Dream offers cost-effective solutions for startups but lacks advanced automation features. Wuhan GEMEI provides mid-range digital systems with strong delivery consistency but limited repeat customer traction, indicating possible gaps in long-term service engagement.

FAQs

How to verify cloth pattern maker supplier reliability?

Validate certifications (CE, ISO) through independent registries. Request factory audit reports detailing quality control procedures, material traceability, and final product testing. Scrutinize customer reviews focused on software stability, mechanical wear resistance, and technical support responsiveness.

What is the typical lead time for standard and custom orders?

Standard units ship within 10–20 days. Customized CNC systems with multi-layer feeding or specialized blades require 25–40 days, including programming and dry-run validation. Air freight adds 5–10 days globally; sea freight ranges from 25–45 days depending on destination port congestion.

Do suppliers support OEM branding and packaging?

Yes, leading manufacturers offer full OEM services—including logo imprinting, branded user manuals, and custom packaging—particularly those with documented customization workflows. Minimum branding thresholds typically apply (e.g., 5+ units).

Are samples available before bulk ordering?

Most suppliers provide functional samples at full or partial cost. Expect to pay 30–70% of unit price for prototype units, refundable upon placement of larger orders. Video demonstrations of cutting cycles are commonly offered as alternatives for initial assessment.

What materials can cloth pattern makers process?

Capable models handle cotton, polyester, wool, knits, non-wovens, PU leather, and laminated fabrics. High-power CNC systems support up to 6mm thickness. Ultrasonic rollers are optimal for heat-sealing synthetic edges without fraying, while oscillating knives suit intricate zigzag patterns in medium-density textiles.