Cnc Automation Robots Manufacturers

CN

CN

Top sponsor listing

Top sponsor listing

1/1

1/1

1/2

1/2

1/3

1/3

1/9

1/9

1/3

1/3

1/7

1/7

0

0

1/3

1/3

1/3

1/3

1/2

1/2

1/15

1/15

1/3

1/3

1/24

1/24

1/16

1/16

0

0

1/1

1/1

1/3

1/3

1/3

1/3

1/31

1/31

About cnc automation robots manufacturers

Where to Find CNC Automation Robots Manufacturers?

China remains the global epicenter for CNC automation robotics manufacturing, with key production clusters in Guangdong and Zhejiang provinces driving innovation and cost efficiency. Shenzhen, within Guangdong, hosts a high concentration of advanced automation firms specializing in collaborative robots (cobots) and integrated CNC tending systems. These suppliers benefit from proximity to semiconductor, electronics, and precision machinery supply chains, enabling rapid prototyping and assembly. Zhejiang’s Wenzhou and Hangzhou regions focus on industrial-grade robotic arms and linear motion systems, supported by mature metal fabrication ecosystems that reduce component lead times by 20–30%.

The regional specialization allows buyers access to both scalable production and engineering customization. Vertically integrated facilities offer end-to-end control—from servo motor integration to final system calibration—within compact geographic zones. This infrastructure supports average delivery cycles of 30–45 days for standard configurations, with custom solutions typically completed within 60 days. Cost advantages range from 15–35% compared to European or North American manufacturers, driven by localized sourcing of structural alloys, drive systems, and control electronics.

How to Choose CNC Automation Robots Manufacturers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm suppliers possess in-house design and programming expertise for CNC integration. Look for demonstrated experience with FANUC, Siemens, or Mitsubishi control interfaces. ISO 9001 certification should be a baseline requirement, with CE marking essential for compliance in EU markets. Request validation documentation for repeatability accuracy (typically ±0.02–0.05mm) and payload testing under continuous operation.

Production Infrastructure Assessment

Evaluate core competencies through facility benchmarks:

- Minimum factory footprint of 3,000m² indicating capacity for dedicated CNC robot assembly lines

- In-house machining capabilities including CNC lathes, milling centers, and precision grinding

- Dedicated R&D teams focused on motion control algorithms and safety protocols (e.g., ISO 10218-1)

- Integration testing bays simulating real-world CNC machine tending workflows

Cross-reference declared response times and on-time delivery rates—targets should exceed 95% fulfillment and ≤4-hour average communication latency.

Sourcing Risk Mitigation

Utilize secure transaction frameworks such as third-party inspection services prior to shipment. Prioritize suppliers with verifiable export histories to your target market, particularly those familiar with customs classification of industrial robots (HS Code 8479.50). Conduct sample trials evaluating setup time, cycle synchronization with CNC equipment, and emergency stop response. For customized integrations, require CAD/3D simulation files before production commencement.

What Are the Leading CNC Automation Robots Manufacturers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Verified Manufacturer |

|---|---|---|---|---|---|---|---|

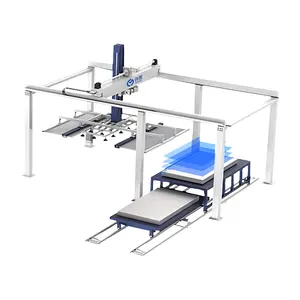

| Shenzhen Era Automation Co., Ltd. | Collaborative Robots, AGV, Material Handling | 100% | ≤2h | 66% | US $260,000+ | N/A | No |

| Zhangjiagang Simbormachinery Co., Ltd. | Manipulator, Collaborative Robots, Conveyors | 100% | ≤4h | 100% | US $140,000+ | N/A | No |

| Wenzhou Chaoxu Machinery Co., Ltd. | CNC Lathe, Plastic Cutting Machines, Punching | 100% | ≤6h | - | - | Color, material, size, logo, packaging, graphic | Yes |

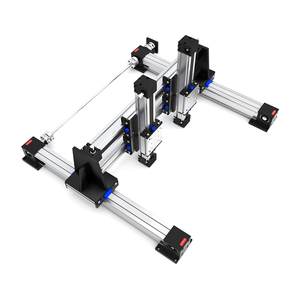

| Shenzhen Jufeng Jingke Automation Technology Co., Ltd. | Linear Robots, Guides, Motor Accessories | 100% | ≤1h | 25% | US $10,000+ | N/A | No |

| Jinan Artech Machinery Co., Ltd. | 6-Axis & 7-Axis Industrial Robots, Heavy-Duty Arms | 87% | ≤3h | <15% | US $540,000+ | Logo, packaging, label | Yes |

Performance Analysis

Shenzhen Era Automation stands out for its high reorder rate (66%) and sub-2-hour responsiveness, indicating strong customer satisfaction in collaborative robot deployment. Zhangjiagang Simbormachinery demonstrates exceptional retention (100% reorder rate), suggesting reliability in manipulator and CNC integration applications. While Jinan Artech reports the highest online revenue, its lower on-time delivery rate (87%) and minimal reorder activity warrant closer due diligence. Wenzhou Chaoxu and Shenzhen Jufeng Jingke achieve perfect on-time performance, with the latter offering the fastest supplier engagement (≤1h). Buyers seeking turnkey CNC tending cells should prioritize companies with proven cobot integration portfolios and documented safety compliance.

FAQs

How to verify CNC automation robot manufacturer credibility?

Audit quality management systems via ISO 9001 certification and request test reports for robot arm lifespan (typically 10,000+ operational hours). Validate export experience through shipping records and client references in regulated industries such as automotive or aerospace.

What is the typical MOQ and pricing range?

Most suppliers set minimum order quantities at 1 unit, with prices ranging from $3,999 for compact cobots to over $70,000 for heavy-duty 6-axis industrial robots. Pricing reflects payload capacity, reach, and control system sophistication.

Do manufacturers support global shipping and installation?

Yes, experienced exporters provide international logistics coordination under FOB or CIF terms. Some offer remote commissioning support; on-site installation services may incur additional fees and require advance scheduling.

Are customization options available for CNC robot integration?

Leading suppliers support mechanical and software-level customization, including stroke length, gripper tooling, communication protocols (Modbus, Profinet), and HMI interface localization. Custom branding and packaging are commonly offered.

What are standard lead times for samples and bulk orders?

Sample units ship within 15–25 days depending on complexity. Full production batches take 30–60 days post-design approval. Expedited timelines may be negotiable for standardized models with available components.