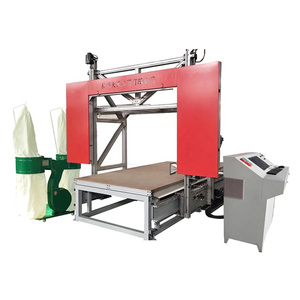

Cnc Foam Cutting Machine Producer

Top sponsor listing

Top sponsor listing

About cnc foam cutting machine producer

Where to Find CNC Foam Cutting Machine Suppliers?

China remains the central hub for CNC foam cutting machine production, with key manufacturing clusters in Shandong, Guangdong, and Henan provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, automated assembly lines, and access to raw materials such as steel, servo motors, and control systems. Shandong’s Qingdao zone specializes in heavy-duty industrial models, leveraging proximity to port infrastructure for efficient global export. Meanwhile, Shenzhen and Foshan in Guangdong focus on advanced automation technologies, including oscillating knife and contour-cutting systems tailored for furniture, packaging, and insulation sectors.

The concentration of component suppliers, R&D centers, and logistics networks within 50km radii enables rapid prototyping and scalable production. Buyers benefit from reduced lead times—typically 30–45 days for standard units—and cost advantages driven by localized supply chains, which lower manufacturing expenses by 20–30% compared to Western producers. The presence of mature machinery parks also supports customization at scale, particularly for multi-axis CNC systems and specialized foam processing applications.

How to Choose CNC Foam Cutting Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international standards such as CE certification, especially for buyers in Europe and North America. Ensure machines comply with electrical safety (IEC 60204) and mechanical design norms. Request documentation for core components—including Siemens or Delta CNC controllers, linear guides, and servo drives—to confirm authenticity and performance benchmarks.

Production Capability Audits

Assess supplier infrastructure using these criteria:

- Minimum factory area of 3,000m² indicating capacity for batch production

- In-house engineering teams capable of custom programming and mechanical design

- Integrated testing protocols for motion accuracy, blade oscillation frequency, and thermal management

Cross-reference declared capabilities with verified metrics such as on-time delivery rates (>97%) and reorder frequency to validate reliability.

Customization & Quality Assurance

Confirm availability of customization options including worktable size (ranging from 1.3x2.5m to 2x4m), cutting thickness (up to 1,500mm), and integration of oscillating knives, hot wires, or rotary modules. Prioritize suppliers offering pre-shipment test runs with video verification and detailed inspection reports. A documented quality management system aligned with ISO 9001 principles is strongly indicative of consistent output.

What Are the Best CNC Foam Cutting Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Sample Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Qingdao Seanoel Industry And Trade Co., Ltd. | Shandong, CN | Foam Cutting Machine (328), Quilting Machines (1670) | US $580,000+ | 100% | ≤1h | 23% | $4,900–$67,000 |

| Shenzhen Zhonglida Machinery Co., Ltd. | Guangdong, CN | Foam Cutting Machine (186), Packaging Machines (99) | US $10,000+ | - | ≤1h | <15% | $7,990–$45,800 |

| Foshan Ligang Automation Technology Co., Ltd. | Guangdong, CN | Foam Cutting Machine (71), Rubber Machinery (137) | - | 100% | ≤5h | - | $13,440 (fixed) |

| Zhengzhou Kinda Electronic Technology Co., Ltd. | Henan, CN | Foam Cutting Machine (featured), Paper Machinery (473) | US $110,000+ | 100% | ≤1h | 66% | $4,900–$10,800 |

| Qingdao Xinmeiteng Sponge Machinery Manufacturing Co., Ltd. | Shandong, CN | Foam Cutting Machine (116), Foam Machinery (34) | - | 100% | ≤3h | - | $21,800–$68,500 |

Performance Analysis

Qingdao Seanoel stands out for high-volume output and diversified product integration, supported by strong online revenue and perfect on-time delivery. Zhengzhou Kinda demonstrates exceptional customer retention (66% reorder rate), suggesting robust after-sales service and competitive entry-level pricing. Shenzhen Zhonglida offers mid-range solutions with responsive communication but lacks verifiable delivery performance. Foshan Ligang provides standardized oscillating knife models at fixed pricing, ideal for buyers seeking predictable costs. Qingdao Xinmeiteng targets high-end applications with premium vertical and rotary CNC systems, reflecting specialization in sponge and EVA processing. All top-tier suppliers maintain sub-5-hour response times, with Shandong and Henan-based firms showing higher compliance consistency.

FAQs

How to verify CNC foam cutting machine supplier reliability?

Cross-check certifications (CE, ISO) through official registries. Request evidence of in-house production, including facility videos and equipment lists. Analyze transaction history focusing on order fulfillment rates, dispute resolution, and buyer feedback related to machine durability and technical support.

What is the typical lead time for CNC foam cutting machines?

Standard configurations require 30–45 days from order confirmation to shipment. Customized models with extended tables or dual-head setups may take 50–60 days. Express production (with surcharge) can reduce timelines to 20 days for select suppliers.

Can suppliers accommodate OEM/ODM requests?

Yes, most suppliers offer OEM labeling, color customization, and interface localization. ODM services include modified gantry designs, integrated conveyors, and proprietary software interfaces. Minimum order quantities typically start at one unit for standard models, with no additional fee for minor branding changes.

Do manufacturers provide machine testing before shipment?

Reputable suppliers conduct full operational tests using sample foam blocks (EVA, PU, EPS). Video validation of cutting accuracy, edge finish, and CNC path execution is commonly provided. Some offer remote live inspections via Zoom or Teams for added transparency.

What are common payment and shipping terms?

Payment structures usually involve 30% deposit and 70% balance before shipment. Escrow and letter of credit options are available for large orders. FOB Qingdao, Shenzhen, or Shanghai are standard; CIF terms are negotiable. Sea freight is recommended for full-container loads due to equipment weight (2,000–8,000 kg per unit).