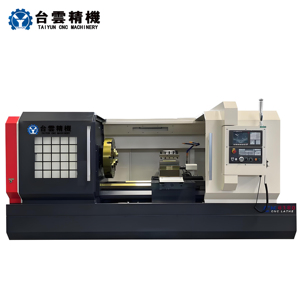

Cnc Lathe Distributor

CN

CN

About cnc lathe distributor

Where to Find CNC Lathe Distributors?

China remains the central hub for CNC lathe manufacturing, with key industrial clusters in Shanghai, Jiangsu, and Liaoning provinces driving global supply. These regions host vertically integrated production ecosystems that combine precision engineering, automated assembly lines, and robust component sourcing networks. Shanghai and Changzhou-based suppliers benefit from proximity to advanced R&D centers and international logistics gateways, enabling faster prototyping and export cycles. Dalian and Wuxi facilities leverage legacy machining expertise and localized steel supply chains, reducing material costs by 15–25% compared to non-specialized manufacturers.

The concentration of technical talent and supporting infrastructure allows for scalable production across both standard and custom configurations. Suppliers typically operate under ISO-certified quality management systems, with many offering in-house CNC programming, tooling design, and automation integration. Buyers gain access to flexible MOQs—from single-unit desktop models to full-container high-capacity lathes—supported by average lead times of 30–45 days for standard orders. The ecosystem supports rapid customization in spindle configuration, control systems, and dimensional specifications, making it ideal for niche industrial applications.

How to Choose CNC Lathe Distributors?

Selecting a reliable distributor requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Verify adherence to ISO 9001 standards as a baseline for process control. For exports to regulated markets, confirm CE marking or equivalent safety certifications. Request documentation on spindle accuracy (±0.01mm tolerance), surface finish quality (Ra ≤1.6μm), and motor performance (servo vs. stepper). Insist on test reports for critical components such as GSK or Fanuc-compatible control systems.

Production & Customization Capability

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house CNC machining, heat treatment, and assembly capabilities

- Dedicated engineering teams supporting customization (e.g., axis travel, chuck size, programming interface)

Cross-reference product listings with declared customization options—color, material, logo, packaging, and system integration—to validate flexibility.

Supply Chain Reliability

Prioritize suppliers with ≥97% on-time delivery rates and response times under 3 hours. Analyze reorder rates as an indicator of customer satisfaction—rates above 30% suggest consistent quality and service. Confirm export experience via transaction volume (e.g., >US$100,000 annual online revenue) and shipping terms (FOB, CIF). Utilize third-party inspection services pre-shipment to verify machine calibration and functionality.

What Are the Best CNC Lathe Distributors?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shanghai Sumore Industrial Co., Ltd. | Shanghai, CN | US $120,000+ | 100% | ≤3h | 27% | 1 set/piece | $1,500–4,000 | Color, material, size, logo, packaging, label, graphic |

| Changzhou Weizhuo Industrial Technology Co., Ltd. | Changzhou, CN | US $10,000+ | 87% | ≤3h | <15% | 1 set | $11,200–12,200 | Color, material, size, logo, model, packaging, label, graphic |

| Dalian Golden Machinery Co., Ltd. | Dalian, CN | US $50,000+ | 100% | ≤1h | 50% | 1 unit | $6,800–9,999 | Color, material, size, logo, packaging, label, graphic |

| Wuxi Fagor Technology Company Limited | Wuxi, CN | US $110,000+ | 100% | ≤3h | <15% | 1 set | $8,900–50,000 | Z-axis travel, turning length, color, material, size, logo, packaging, label, graphic |

| Zaozhuang Wojie CNC Machinery Co., Ltd. | Zaozhuang, CN | US $540,000+ | 100% | ≤2h | 33% | 1 set | $5,500–27,000 | Motor, tool holder, turret, lubrication system, control system, material, size, logo, chuck, packaging, label, non-standard specs, graphic, heat exchanger |

Performance Analysis

Zaozhuang Wojie CNC Machinery leads in transaction volume and customization depth, offering over 13 configurable parameters including control systems and thermal management—ideal for engineered-to-order projects. Dalian Golden Machinery stands out with a 50% reorder rate and sub-hour response time, indicating strong post-sale support and reliability. Shanghai Sumore provides entry-level mini-lathes at competitive prices ($1,500–4,000), suitable for small workshops or educational use. Changzhou Weizhuo maintains uniform pricing across multiple 4-axis models but shows lower repeat order activity, suggesting room for improvement in long-term client retention. Wuxi Fagor targets high-end applications with machines priced up to $50,000, supported by extensive configurability in motion dynamics and structural dimensions.

FAQs

How to verify CNC lathe distributor reliability?

Cross-check ISO/CE certifications with accredited bodies. Request facility videos or virtual audits to confirm in-house production capabilities. Review transaction history, focusing on on-time delivery consistency and dispute resolution records. Validate customer feedback related to machine precision, software compatibility, and after-sales technical support.

What is the typical lead time for CNC lathes?

Standard models are typically delivered within 30–45 days after order confirmation. Custom-configured units may require 50–70 days depending on complexity. Expedited production is available from select suppliers for urgent requirements, subject to surcharges.

Do distributors offer global shipping?

Yes, most established suppliers manage international logistics via sea freight (FCL/LCL) or air cargo for samples. Confirm Incoterms (FOB, CIF) and ensure compliance with import regulations in the destination country, particularly for electrical and mechanical equipment.

Are free samples available?

Sample policies vary. Some suppliers provide demo units or partial refunds upon bulk purchase, while others charge full sample cost. Expect sampling fees to cover 30–50% of unit price, especially for high-value machines. Pre-production prototypes may be offered for custom designs.

What customization options are commonly supported?

Key customizable elements include spindle type (single/twin), axis count (2–4 axes), bed length, control system (GSK, Siemens, Fanuc), tool turret configuration, motor power, and safety enclosures. Suppliers also accommodate branding (logo, color), packaging, and compliance labeling for OEM partnerships.