Cnc Machine China

Top sponsor listing

Top sponsor listing

1/16

1/16

CN

CN

1/7

1/7

1/13

1/13

1/11

1/11

1/24

1/24

1/18

1/18

About cnc machine china

Where to Find CNC Machine Suppliers in China?

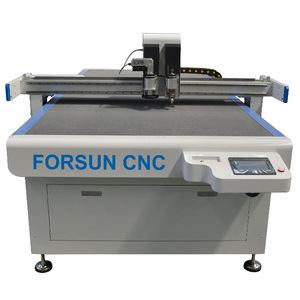

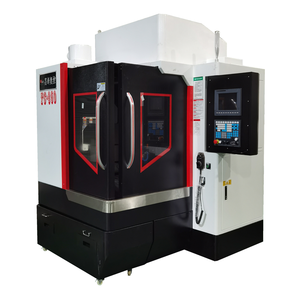

China remains the world’s largest producer of CNC machines, with key manufacturing clusters concentrated in Shandong and Guangdong provinces. Shandong hosts a dense network of machine tool manufacturers specializing in vertical machining centers, CNC lathes, and industrial-grade routers, supported by regional steel and casting industries that reduce raw material costs by 15–20%. Dongguan in Guangdong province focuses on precision metal components and custom machining services, leveraging proximity to high-tech electronics and automotive supply chains.

These industrial hubs feature vertically integrated production ecosystems—encompassing casting, heat treatment, CNC processing, and final assembly—within tightly clustered geographic zones. This integration enables lead times as short as 30 days for standard models and supports scalable output for bulk orders. Buyers benefit from localized component sourcing, mature technical labor pools, and streamlined logistics, achieving 20–30% lower total procurement costs compared to equivalent equipment sourced from Europe or North America.

How to Choose CNC Machine Suppliers in China?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

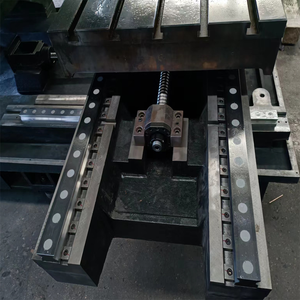

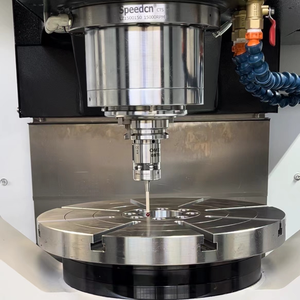

Verify adherence to international quality standards such as ISO 9001. For export markets, confirm CE marking or compliance with regional safety directives (e.g., OSHA, IEC). Request documentation on spindle accuracy (≤0.005mm runout), positioning repeatability (±0.01mm), and control system specifications (Fanuc, Siemens, GSK).

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for dedicated CNC production lines

- In-house capabilities covering milling, turning, drilling, and mold making

- Engineering support for customization, including CAD/CAM design and prototype validation

- On-time delivery rate exceeding 94% as an indicator of production reliability

Transaction Risk Mitigation

Utilize secure payment structures such as escrow or letter of credit for initial large-volume orders. Prioritize suppliers with documented reorder rates above 25%, indicating customer satisfaction and post-sale support effectiveness. Conduct pre-shipment inspections to validate machine calibration, component origin, and software integration before release of final payment.

What Are the Leading CNC Machine Suppliers in China?

| Company Name | Location | Verified Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Dongguan Thriving Metal Parts Co., Ltd. | Guangdong, CN | Custom Manufacturer | Sheet Metal Fabrication, Machining Services, Moulds, Casting | US $480,000+ | 94% | ≤2h | 36% | Yes (drawings, materials, labeling, packaging) |

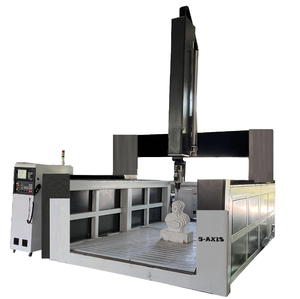

| Shandong Guandiao CNC Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | Woodworking CNC Routers, 3D Carving Machines | US $670,000+ | 100% | ≤2h | 22% | Yes (spindle speed, control system, frame material) |

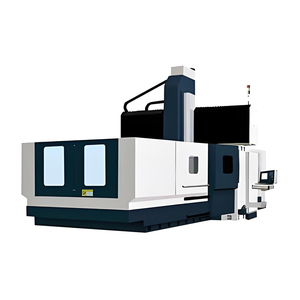

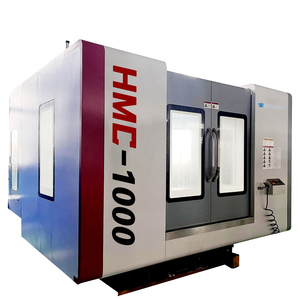

| Shandong Weste Cnc Machine Tool Co., Ltd. | Shandong, CN | Not Specified | Machining Centres, CNC Milling Machines, CNC Lathes | US $30,000+ | 100% | ≤3h | 100% | Limited (model-specific configurations) |

| Shandong Yijin Cnc Machine Tool Co., Ltd. | Shandong, CN | Not Specified | Machining Centres, CNC Lathes, Planer Machines | US $40,000+ | 100% | ≤1h | 50% | Yes (multi-axis configurations, control systems) |

| Shandong Mainland Cnc Equipment Co., Ltd. | Shandong, CN | Not Specified | CNC Lathes, Vertical Machining Centres, Band Saws | US $180,000+ | 100% | ≤3h | 25% | Yes (brand-specific controls, model variants) |

Performance Analysis

Shandong-based suppliers demonstrate strong logistical reliability, with all listed companies achieving 100% on-time delivery. Shandong Guandiao and Shandong Yijin stand out for responsiveness (≤2h and ≤1h average reply time) and robust revenue performance, indicating established export operations. Notably, Shandong Weste reports a 100% reorder rate—suggesting high end-user satisfaction despite lower online visibility. Dongguan Thriving offers extensive customization depth across materials (aluminum, brass, PEEK), surface treatments (anodizing, brushing), and dimensional tolerances, making it suitable for precision OEM applications. Buyers requiring multi-axis machining should prioritize suppliers listing 5-axis CNC centers and Fanuc/Siemens control compatibility.

FAQs

What certifications should CNC machine suppliers have?

Essential certifications include ISO 9001 for quality management. Export-oriented suppliers should also provide CE marking for compliance with European machinery directives. Additional standards like RoHS may apply for components used in electronics manufacturing.

What is the typical MOQ and lead time for CNC machines?

Minimum order quantity is typically 1 set for standard machines. Lead times range from 30 to 45 days depending on complexity—basic 3-axis routers ship faster, while 5-axis vertical machining centers may require additional calibration and testing.

Can suppliers customize CNC machines for specific applications?

Yes, most suppliers offer configuration options including spindle power (1.5kW–15kW), control systems (GSK, Syntec, Fanuc), table size (6090, 1300x2500mm), and automation features (auto-lubrication, swing head). Custom branding, voltage adaptation (380V/50Hz vs. 220V/60Hz), and software integration are commonly available.

Do suppliers provide technical support and installation assistance?

Leading suppliers offer remote setup guidance via video and manuals. Some provide on-site commissioning services at additional cost. Confirm availability of English-language documentation, troubleshooting guides, and spare parts inventory prior to purchase.

How are CNC machines packaged and shipped internationally?

Machines are secured in seaworthy wooden crates with anti-vibration mounts. Most suppliers support FOB Qingdao, FOB Shanghai, or CIF terms. Sea freight is standard for full-container loads; air shipping is feasible only for compact desktop models due to weight and size constraints.